Express service for loading a submarine cable laying vessel

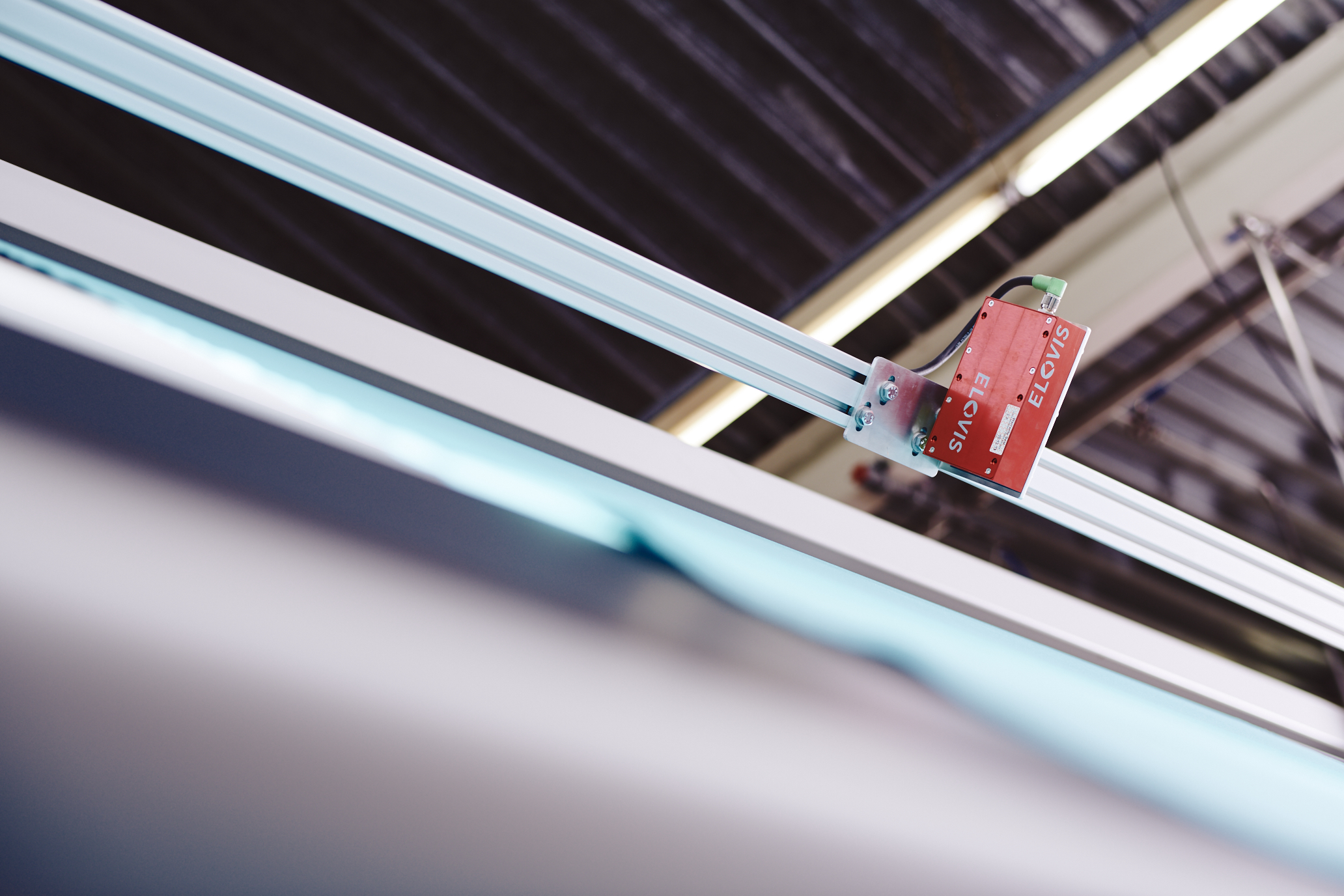

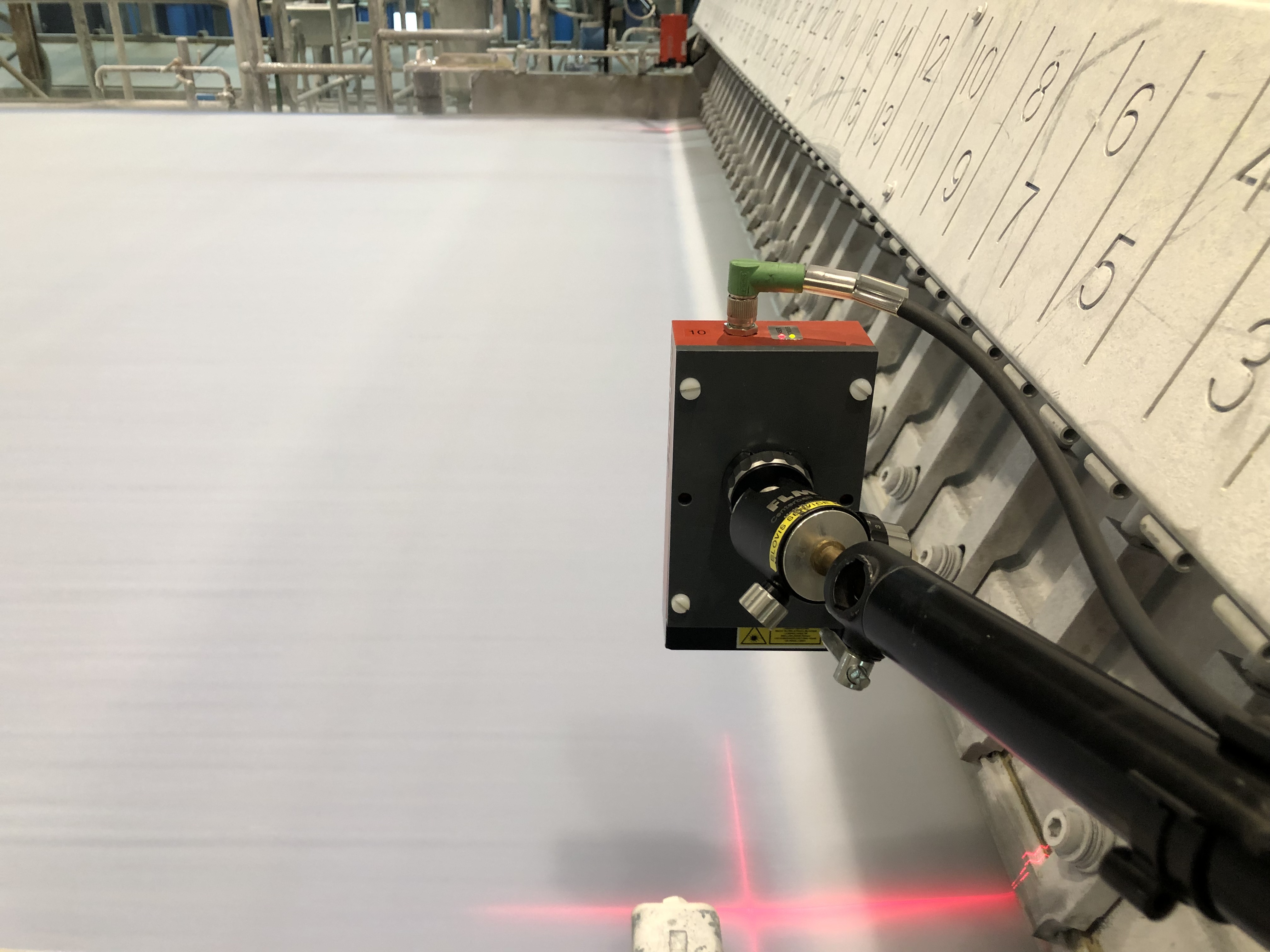

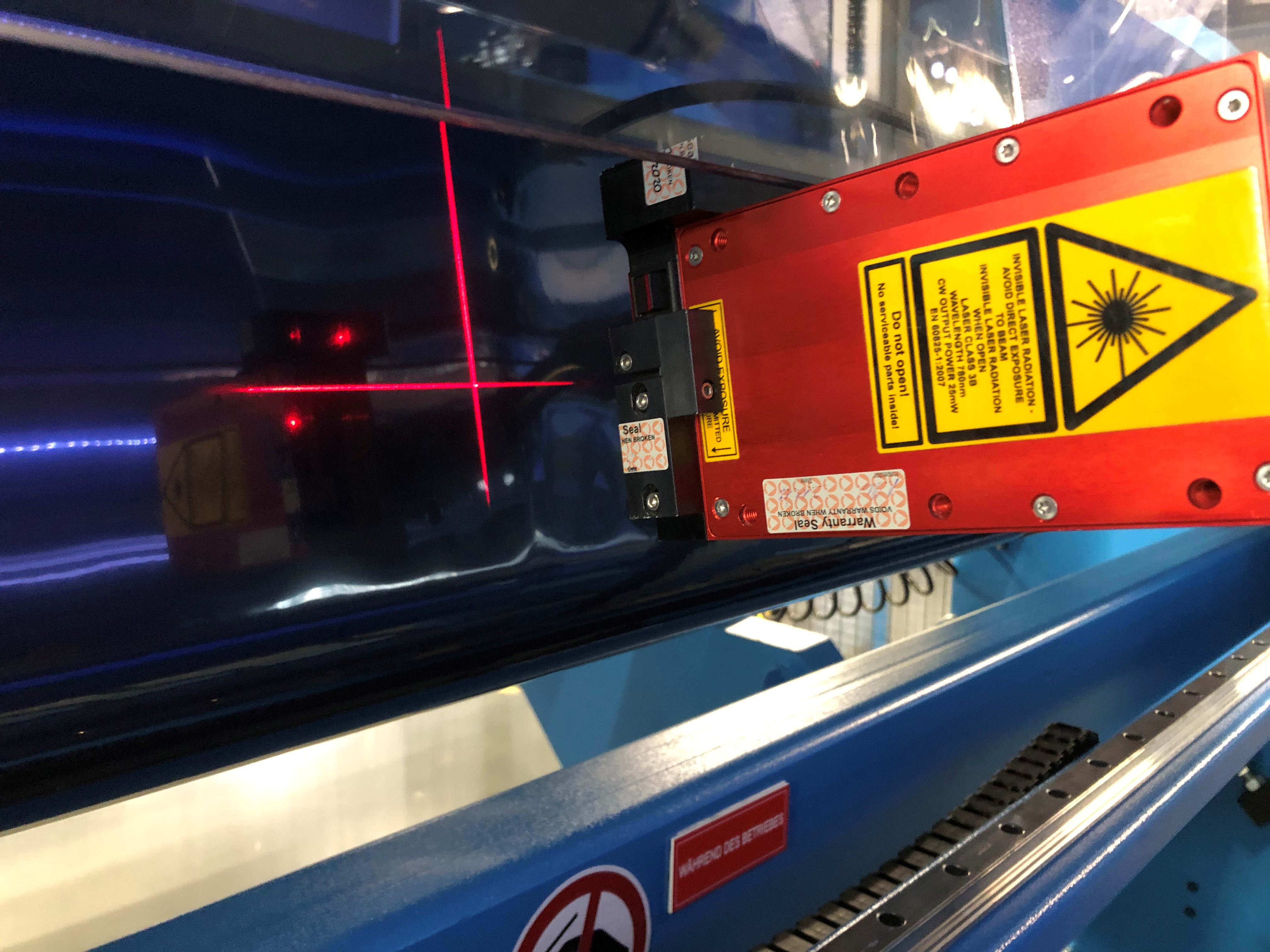

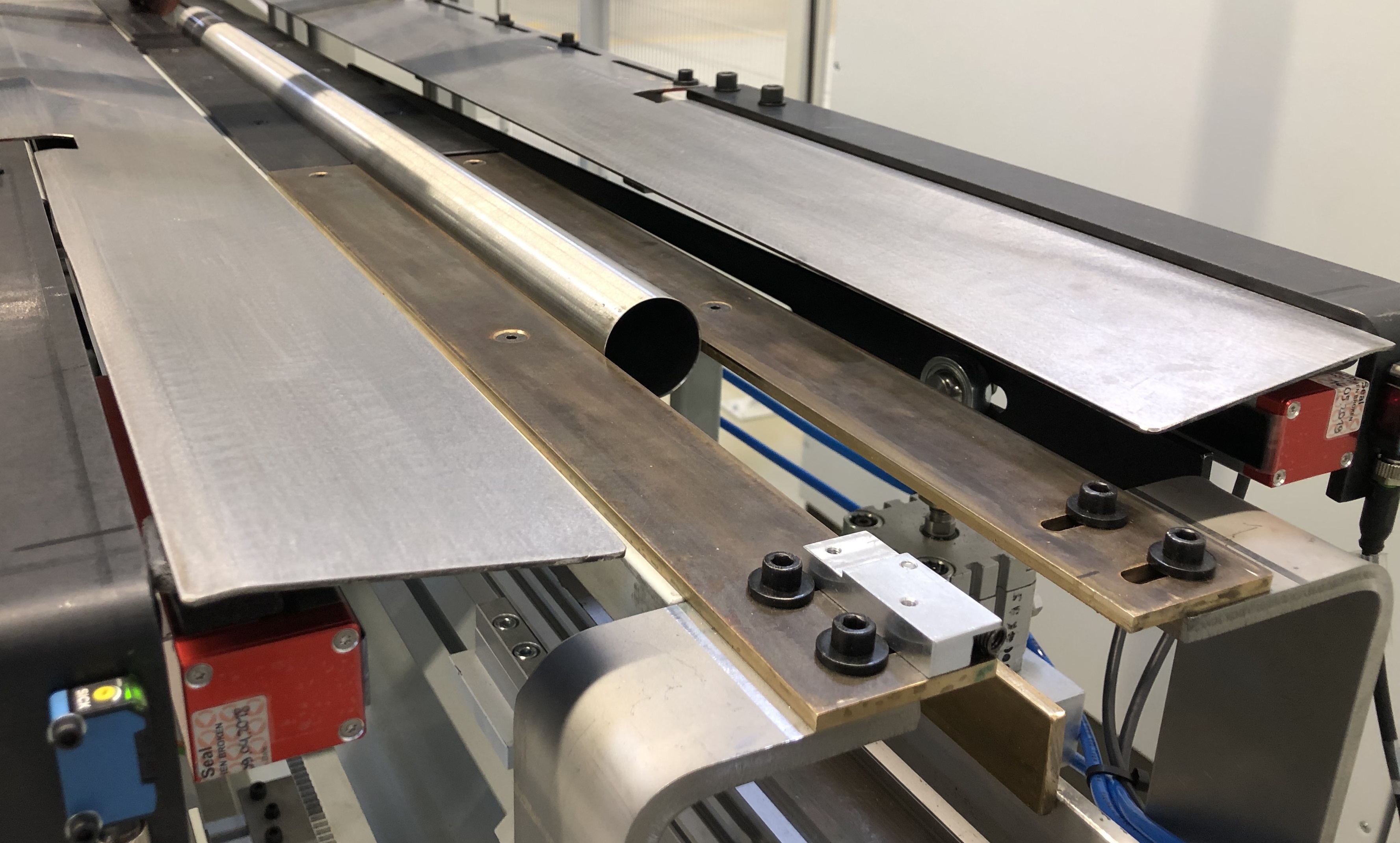

Storing the exact length of submarine power cables Mission description: Due to the lack of a reliable length measurement for charging and cutting to length from an exact specified submarine cable length, the operational command of the submarine cable displacement vessel decided to request an express service from ELOVIS. The length measuring equipment available on … Weiterlesen …