ELOVIS Measurement Solutions for Extursion Industry

ELOVIS offers special measuring solutions for the extrusion industry. Measuring tasks for line optimization, for cut control and for remeasuring profile part lengths and profile geometries (height and width) are covered. µSPEED laser encoders are used for speed and length measurement tasks as well as for cut control. Also used are SLM longitudinal light sensors for precise length measurement on cut parts and the µVIS systems for geometry monitoring. Some typical examples of measurement solutions in the extrusion industry are listed here.

Non-contact measurement of discrete part lengths – ELOVIS Measurement Solutions for Extrusion Industry:

- Profile length check after cutting

- Pipe / tube length check after cut

- Good / waste length sorting

- Cutting optimization

Control of length cutting – ELOVIS Solutions for Extrusion Industry:

- Measurement at endless materaial before saw / knife

- Control of flying saws / knifes

Non-contact speed measurement – ELOVIS Measurement Solutions for Extrusion Industry:

- Profile speed measurement after the die

- Speed measurement for haul-off control and saw synchronisation

- Velocity measurement to prevent or detect break-off

Width / height non-contact measurement – ELOVIS Measurement Solutions for Extrusion Industry:

- Profile width, profile height

- Strip width, stip evenness

Extrusion Industry - Application Examples

Length Measurement of profiles after cutting

High demands of the automotive, furniture, electronics or medical industry on the cutting accuracy of profiles make t...

Length Measurement of pipes after cutting

The final measurement of all tubes after the cutting allows a shortening of the setup time of the cutting system and ...

Test station for final part length measurement

If discrete part lengths are to be measured quickly and reliably and the measurement length has to be documented, the...

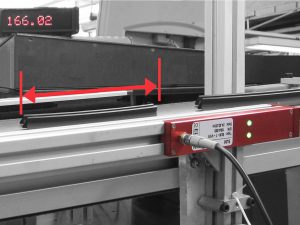

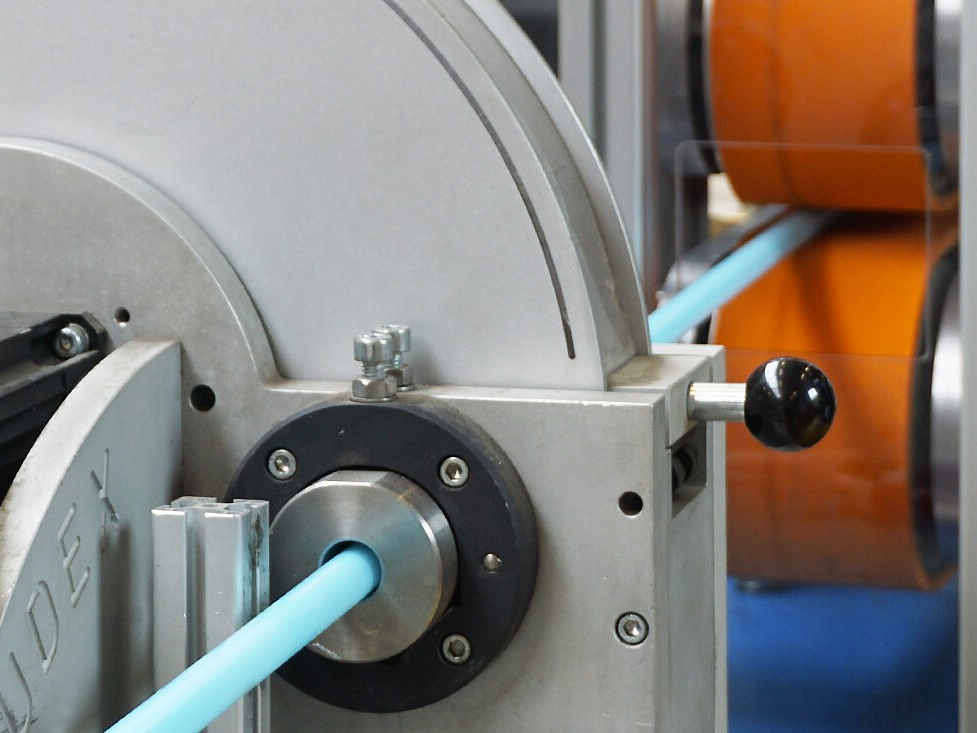

Cutting Control in Pipe/Profile Extrusion

When sawing and cutting extruded materials, such as pipes, hoses and profiles, a slip-free length measurement is esse...

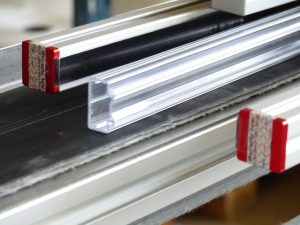

Length of transparent plastic profiles

Even the final length measurement of translucent plastic profiles is easily and accurately possible with the non-cont...

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

ELOVIS Services

ELOVIS offers the following services for the extrusion industry:

- Consulting on the subject of length and speed measurement

- Measurement and calibration services

- Machine trouble shooting by speed measurement

- Help with system malfunctions

- OEM sensor developments in the field of length and speed measurement