Synchronous wireless data transfer via wireless network, wireless measurement of vibration and oscillation.

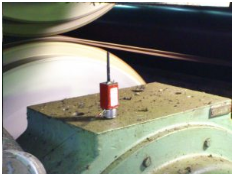

When troubleshooting complex objects (machines, buildings, structures, …), the measurement of vibrations, speeds, temperatures, pressures or other measured variables must often be carried out quickly and easily at different measuring points simultaneously. Laying sensor cables is the most time-consuming part of the measurement campaign and can take longer than the measurement itself in many cases. In some measuring applications, however, cables may interfere with the measurement, or cables can only be laid after the machine has been switched off due to moving machine parts. If the measuring point itself moves or rotates, sensors with cables cannot be used. … ELOVIS TEDIASENS sensor nodes type SN-I (Sensor-Node-Internal) are equipped with a 3-axis accelerometer, a rechargeable battery and a radio module. The radio nodes without integrated accelerometer are called SN-X (Sensor-Node-Extermal) and have instead 3 BNC sockets for the connection of various commercially available sensors. Both radio nodes are small and powerful. The radio nodes can transmit measurements over 9 hours in continuous operation. Typical radio distances are 20m to 100m. Up to 40 radio nodes, each with 3 channels can be operated simultaneously.

Wireless synchronous measurement data transfer

Should measurement data be transmitted wirelessly and synchronously? You do not find a sufficiently powerful, self-su...

Vibration & Oscillation Measurement

In trouble shooting, vibration measurements must be carried out quickly and easily at different measurement points. C...

Long-Term Monitoring

Measurement Data Logging

Object states should be monitored over a longer period of time at regular intervals, whereby the test data and any al...

Wireless data transmission and wireless vibration measurement: You will find here the wireless ELOVIS data transmission systems and vibration & oscillation measurement equipment. The advantages resulting from the use of these measuring devices are named afterwards.

ELOVIS data transmission systems, wireless, synchronous:

- Wireless system series

- Sensor node, radio node, self-organizing radio network

- Radio node with integrated sensors

- Radio node for external sensors

- Long-term monitoring and data logging

- Velocity measurement system with radio data transmission

TEDIASENS

Measurement advantages with ELOVIS wireless measurement devices:

- small, light, self-sufficient ⇒ 1000 m cable replacement in a briefcase

- quickly set up and put into operation ⇒ no cabling required

- Radio technology over long distances ⇒ avoids cable breakage problems with long cable lengths

- Synchronous technology ⇒ no disadvantages compared to cables

- Suitable for high bandwidth ⇒ powerful data transmission system

Wireless data transmission and wireless vibration measurement: The list shows applications for ELOVIS wireless vibration measuring devices.

Wireless synchronous measurement data transmission:

Fast operational readiness in service – self-sufficient for over 8 hours and longer

Wireless vibration measurement and oscillation measurement:

Fast operational readiness for trouble shooting with high-performance wireless vibration measurement system.

Long-term monitoring and measurement data recording:

Condition monitoring over longer measuring time with alarm for limit value overflow, data storage and pre-trigger data logging

Wired Data Transmission and Vibration Measurement: This section lists typical traditional and mostly wired measurement data transmission systems and vibration & oszilation measurement equipment. The measuring problems resulting from the use of these measuring devices are listed here.

Traditional, wired sensors:

- Wired accelerometers

- wired temperature and humidity sensors

- wired pressure and force sensors

- rotation speed Sensors

- Speed Sensors

Problems with wired data recording systems:

- Working time and labor when installing the sensors at different measurement points

- Huge weight of cables (ergonomics, transport costs, travel expenses)

- Problem of work safety because cable laying is often necessary in safety-critical machine areas

- Cost of production loss if machine downtime is required to install cable-based sensors

Wireless data transmission and wireless vibration measurement: The following industries are using wireless ELOVIS measuring equipment.

Mechanical Engineering:

- Paper and board machines

- Rolling machines

- Sieves, classifiers, mills

- Drives and transmissions of large machines

- Gear Manufacturer

Construction industry:

- Bridge monitoring

- Building monitoring

- Tunnel monitoring

- Building supervision (fans, air conditioners, …)

Transportation industry:

- Luggage Monitoring

- Packet monitoring

Wireless data transmission and wireless vibration measurement: List of some videos of ELOVIS vibration measuring instruments in industrial use:

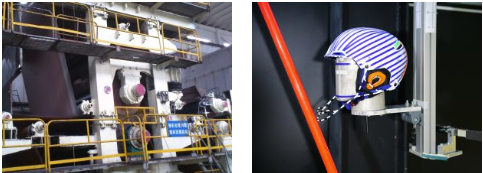

| Application Video – Impact Test on a Ski Helmet

Wireless data transmission and wireless vibration measurement |

|