Divided Measurement System for Discrete Part Length Measurement on parts up to approx. 15 m

μMETER-SLM/2 sensors are measurement systems with each, a divided transmitter and a divided receiver array for non-contact discrete part length measurement of goods during their longitudinal movement. SLM/2 systems are used for the final measurement of parts with a length of 5 m up to apprx. 15m, or if structurally no continuous SLM measurement arrays can be used. SLM/2 is generally permanently installed. To enlarge the length measuring range, it is also possible to connect several SLM/2 gauges in series, or to mount one of the two pairs of light arrays so that it can be moved (e.g. on a rail). SLM/2 gauges are pre-calibrated ex works. However, the entire system can only be calibrated in the course of installation on site using reference parts. The typical measurement accuracy of the system is +/- 0.1 mm per meter measuring length. SLM/2 systems are used for production optimization, good/bad sorting and documentation of the delivery quality status of discrete parts. SLM systems work without contact, are maintenance-free and measure largely independent of material. Typical measurement materials are profiles, tubes, plates, sheets, boards, beams, bolts, … made of the most diverse materials.

Product Types – SLM/2 divided measurement system for discrete part length measurement of long parts up to 15 m length

Technical Data – SLM/2 divided measurement system for a discrete part length measurement on long parts up to 15 m length

| µMETER | SLM/2-Lx |

| System Components | Two-parted transmitter and two-parted receiver arrays |

| Types | Measurement range of max. 4,5 m (e.g. for part lengths of 10 m to 14,5 m) |

| Measurement Material Length | typical 5 m to approx. 15 m (based on the project conditions) |

| Systematical Measurement Accuracy | ± 0,1 mm/m (based on the project conditions) |

| Repetitive Accuracy | ± 0,03 mm (confidence interval 1σ) |

| SLM Arrangement of Transmitter and Receiver to each other | Horizontal, vertical or diagonal |

| V-Measurement Range | Depending on sensor length and module distance |

| Measurement Distance between Transmitter and Receiver Arrays | 150 mm to 1.000 mm |

| Interfaces | 1 x RS-485 |

| I/Os | Input: Start, Gate, Calibration Output: Status |

| I/O Type | RS‐422 Gauge |

| Available Data | Speed, Length, Signal Quality, Status, Valid Measurement |

| Feldbus | Optional: Profibus-DP, ProfiNet‐RT, Ethernet‐IP, … |

| Protection Class | Sensor Arrays: IP50 |

| Dimensions (LxWxH) |

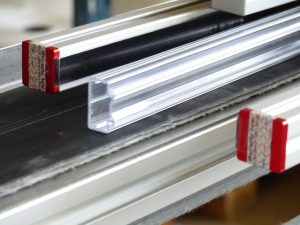

Sensor Arrays: 30x30mm Profil cross section, Bosch-Rexroth, Length depending on maximum measurement material length |

| Power Supply | 12 – 24 VDC |

| Weight | Sensor Arrays: Depending on length – ca. 1 kg per meter of gauge array |

| LED Data | 5mW, Infrared |

| Ambient Temperature | 5 to 55°C ‐ not condensing, outside of temperature range external cooling / heating required |

| Humidity | Environment should be dry |

Accessories – SLM/2 divided measurement system for discrete part length measurement on long parts up to approx. 15 m length

Standard Interface |

|

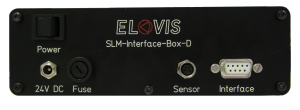

Interface Box for PC Operation SLM-BOX |

Interface box for connecting the SLM system to a PC or laptop. Allows for easy connection and supply of the SLM sensor. With RS485 output interface and plug-in power supply. |

Sensor Cable |

| Shielded Cables

SLM-K3, K10 |

Sensor cable for connecting the two SLM sensor lines with each other and for connection to an interface such as SLM box or bus module, a controller or a display. |  |

Displays and Control Units |

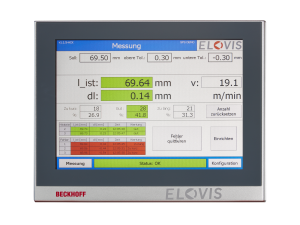

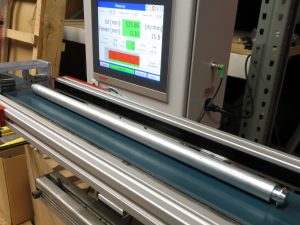

| Length Display

SLM-DISPLAY-BOX |

Interface box with length display for connecting the SLM system to a PC or laptop. Box with RS485 output interface and plug-in power supply. | |

| Control/Control Unit

SLM-CONTROLLER |

Display and Control Unit for the SLM sensors provide the following features:

|

|

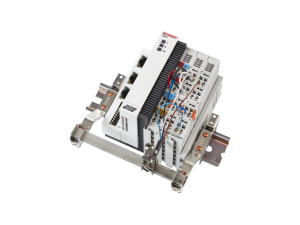

| Sorting Control

SLM-SPS |

The SPS sorting control for the SLM sensors provide the following features:

|

Mobile Equipment |

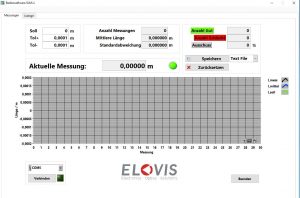

Software |

Feldbus and Communication Modules |

| Profibus-DP, ProfiNet-RT, Ethernet-IP

µSPEED-PB, µSPEED-PN, µSPEED-EN |

Standard bus interface modules with the following output: Length (in m) , speed (in m/s), status signal (valid/invalid) |

Protective Casing |

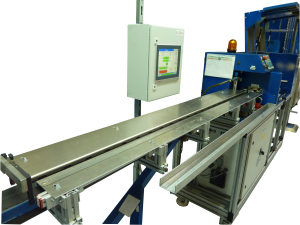

Conveyor Technology and Sorting Technology |

| Conveyor Technology and Sorting Technology | Conveyor technology, conveyor belts, carriages, slide rails, push-out devices and sorting machines are offered together with experienced partner companies. |

µMETER-SLM/2 – Divided Measurement System for Discrete Part Length Measurement on long parts up to approx. 15 m length

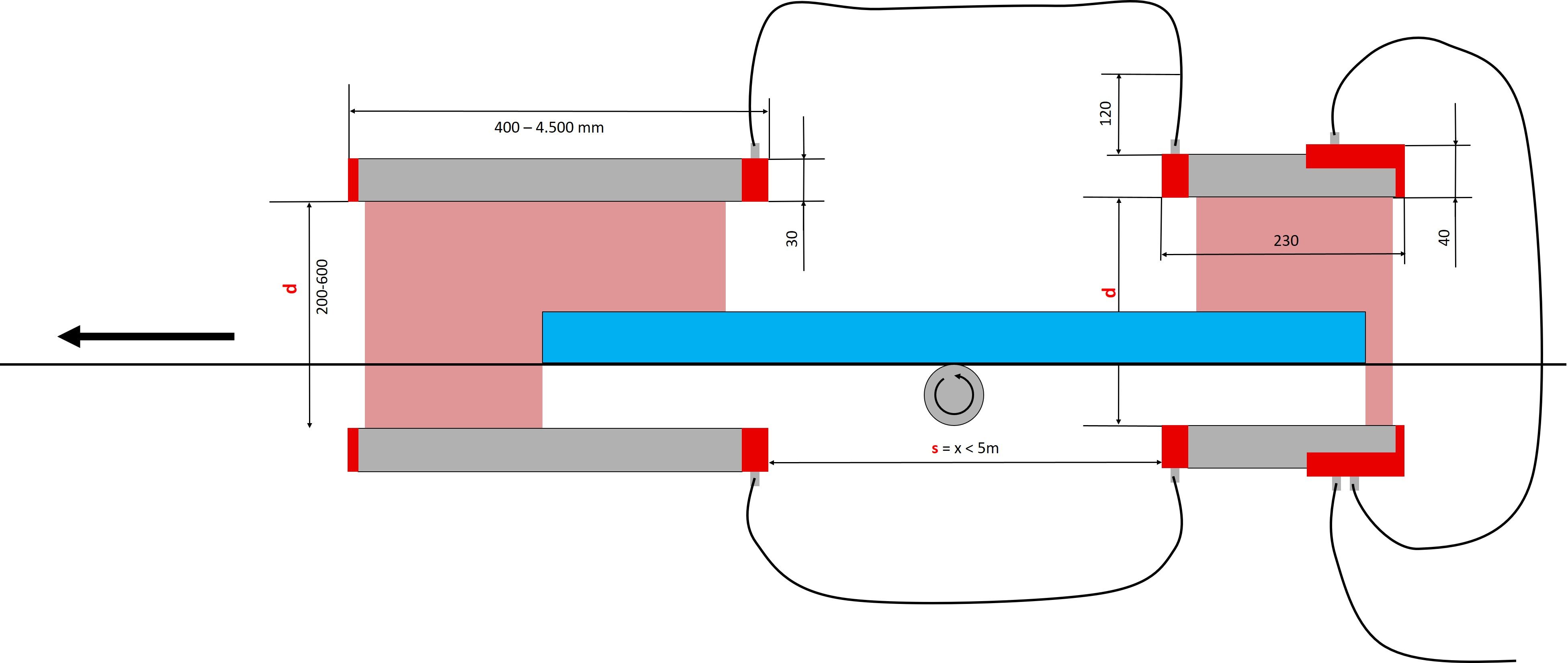

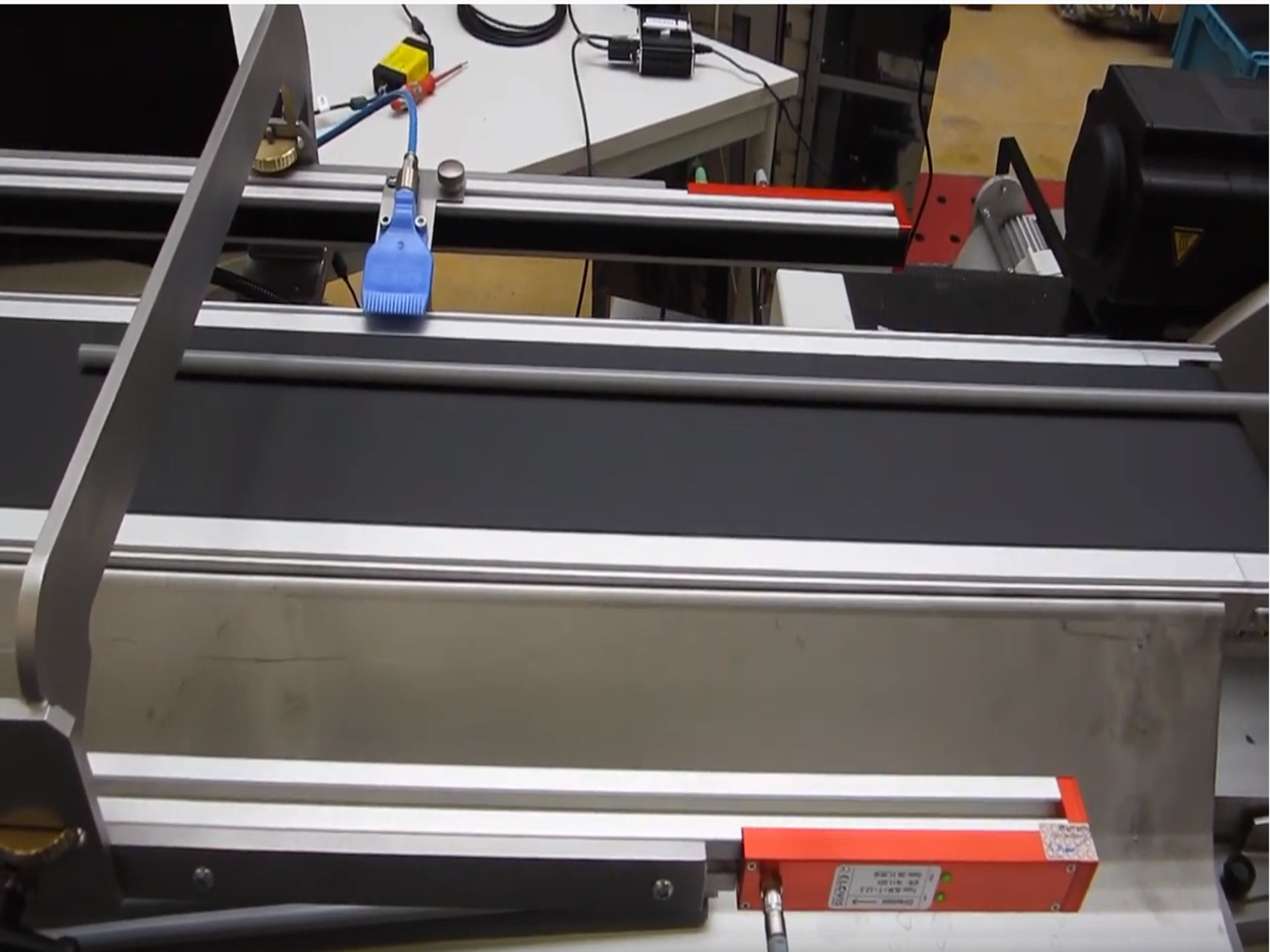

SLM/2 gauges consist of each, a divided transmitter and a divided receiver array for non-contact discrete part length measurement of parts during their longitudinal movement. SLM/2 systems are used for the final measurement of parts with a length of 5 m up to apprx. 15m, or if structurally no continuous SLM measurement arrays can be used. The discrete part to be measured passes the SLM/2 System without stopping in longitudinal direction. As soon as discrete part is located completely between both pairs of sensor arrays which are connected by cables (both with a light transmitter array and a receiver array), a measurement is automatically triggered. To ensure that the measurement can take place with high accuracy, the discrete part already has to be separated during measurement, however, a distance between two subsequent discrete parts of only 50 mm in between two parts is sufficient. In addition, the measurement object should pass the SLM system as straight as possible, because the SLM gauge measures the shadowing of the measurement object in the transmitted light. If the measurement object is twisted or inclined, the measured projection can cause a measurement which is rather too long or too short, depending on the object’s width and torsion. Furthermore, it is beneficial, if the edges of the measuring object are cut with right angles and there are no ridges, cutting waste or chips left over on the front and end surface. The active measurement array is only approx. 2 mm high and is located in the middle of the sensor profile, which has a cross-section of 30 x 30 mm.

SLM/2 principle drawing (side view):

SLM standard – working concept:

Videos – SLM/2 divided measurement system for discrete part length measurement on long parts up to 15 m length

| Product-Tutorial – SLM

Length-Section Light Scanner Part Length Measurement Systems – SLM Setup |

|

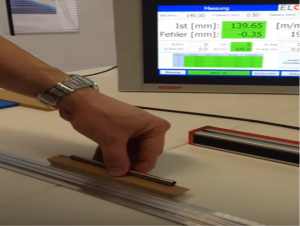

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems – Manual Tube Measurement |

|

| Application Video – SLM/2

Length-Section Light Scanner Part Length Measurement Systems – Length Measurement System for long discrete parts SLM/2 – Aluminium profiles |

|

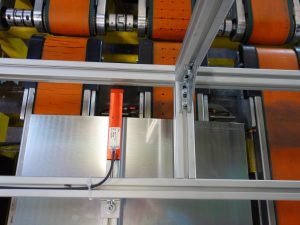

| Application Video – SLM/2

Length-Section Light Scanner Part Length Measurement Systems – Length Measurement System for long discrete parts SLM/2 – tubes |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems -Measurement of profile length with SLM |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Measurement of film sheet length after cutting, before sorting/packaging |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Length Measurement on cut tubes |

|

| Application Video – SLM

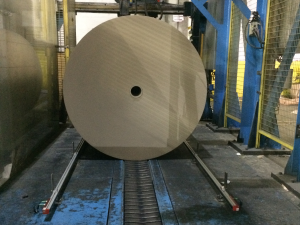

Length-Section Light Scanner Part Length Measurement Systems Width Measurement of rolls |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Part Length Measurement on short plastic profiles at high speeds |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Part Length Measurement of 354 mm long plastic profiles after extrusion and cut |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Small tubes in manual part guidance |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Width Measurement of Rolls with SLM |

|

APPLICATIONS

Measure piece lengths up to 5m

in transmitted light

Do you still measure piece lengths by hand in samples? Incoming and outgoing material edges ensure increased wear and...

Measure part length up to approximately 15 m

in transmitted light

The final measurement of very large parts is complex, staff-intensive, but still prone to error. If the maximum measu...

Length Measurement of long parts

in reflection

The measurement situation prevents the use of a transmitted light system for part length measurement? The space avail...

Measure part lengths

with free-form edges

You want to measure the length of parts with free-form edges? ... With the μVIS based 2D and 3D sensors a variety of ...

APPLICATION EXAMPLES

Length Measurement of profiles after cutting

High demands of the automotive, furniture, electronics or medical industry on the cutting accuracy of profiles make t...

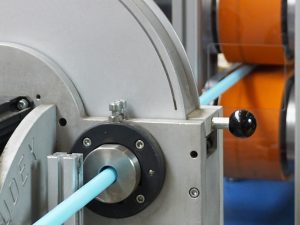

Length Measurement of pipes after cutting

The final measurement of all tubes after the cutting allows a shortening of the setup time of the cutting system and ...

Test station for final part length measurement

If discrete part lengths are to be measured quickly and reliably and the measurement length has to be documented, the...

Length Measurement of sheets and plates

Metal sheets and boards are cut and then palletized. A final measurement is often done manually on the pallet stack. ...

Length Measurement of window profiles

Window profiles with lengths between 2.5 m and 7 m should be cut as precisely as possible and checked directly after ...

Measure the length of wood and chipboard

The woodworking industry is now confronted with high accuracy requirements. In order to make a profit, it is importan...

Width of paper rolls on the chain conveyor

Paper rolls are transported to the warehouse via chain conveyors after wrapping. Prior to storage, the rolls of paper...

Length of transparent plastic profiles

Even the final length measurement of translucent plastic profiles is easily and accurately possible with the non-cont...

Measure the length of metal parts, pipes, bolts, slugs

Metal parts such as pipes, bolts, rods, slugs should have the correct part length. When operating presses and forging...

Weerth - cutting and measuring precision pipes and tubes

Weerth Handling Systeme manufactures systems for the non-cutting and burr-free cutting of metal pipes and tubes. For ...

ROBUST - Foil cutting machine with part length measurement

ROBUST is specialized in slitting machines and winding technology. The product range includes roll slitting and windi...

EXTRUDEX - extruder with guillotine and measuring unit

EXTRUDEX is a manufacturer of extruders and cutting devices. EXTRUDEX extruders are mainly used in the automotive and...