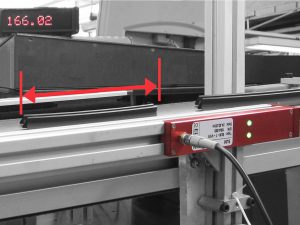

segmenting station including non-contact length measurement

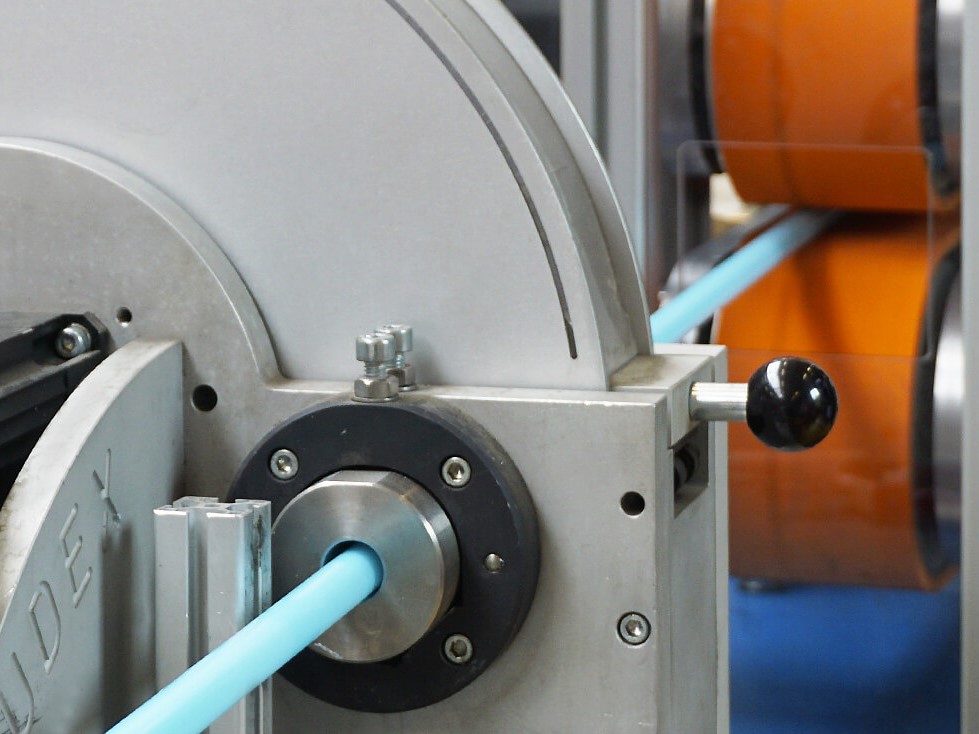

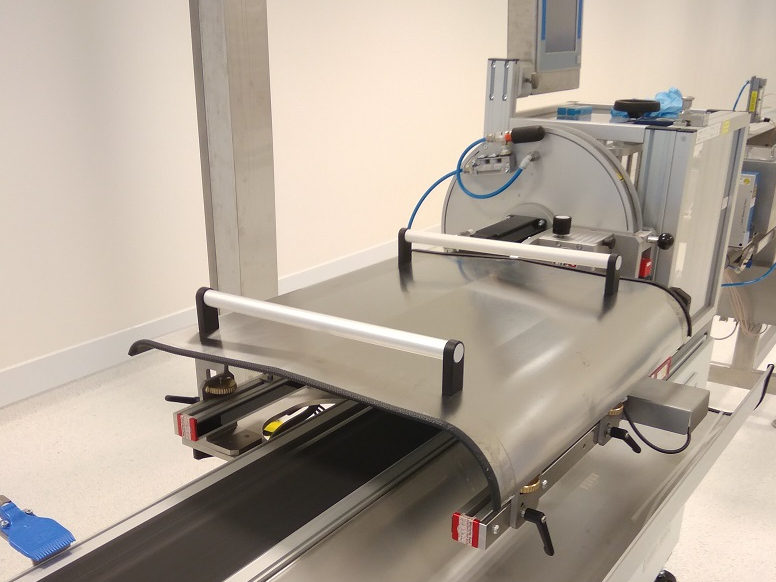

EXTRUDEX is a manufacturer of extruders and cutting devices. EXTRUDEX extruders are mainly used in the automotive and medical technology sectors as well as in the cable industry. EXTRUDEX uses ELOVIS SLM systems for length testing and documentation following cutting devices. In the application shown here, PU pipes are manufactured.

Typical application data:

- Measurement of PU-tube after cutting, before sorting / packaging

- Production speeds: typically up to 15 pcs/sec or 120m/min

- Cutting system without SLM system: only random sample inspection possible, accuracy: +/- 0.5mm/m

- 100% measurement with non-contact length measurement SLM, typical accuracy: 0.1mm/m

- Amortization: 2 months, integration of the measuring system into Weerth Anlagentechnik

Material examples:

- PU-tube, precision tube

- Diameter: from 6 mm to 40 mm

- Length range: 50 mm x 400 mm

- Tube-material: PU

EXTRUDEX machines, which are extended by non-contact length measurement:

- Extruder and downstream equipment

- Cutting machines and segmenting stations

- Guillotines

- Precision saws

- Double rotary cutter

Matching Products and Services

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

ELOVIS Services

ELOVIS offers the following services for the measurement of tubes, pipes and profiles:

- Advice on discrete part length measurement

- measurement services

- Help with length complaints of your customers

- OEM sensor developments in the area of piece length measurement