Machine Control, Calibration of Tachometers, … by speed detection

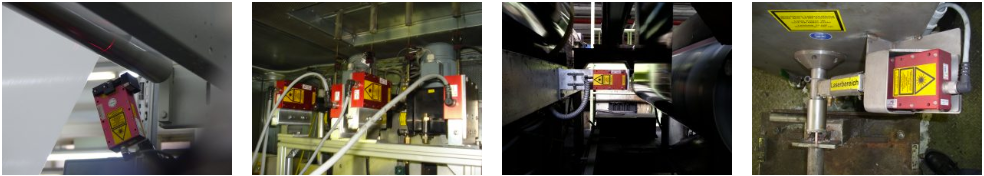

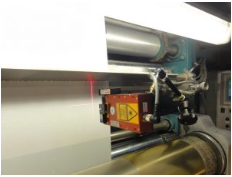

ELOVIS systems for motion and speed measurement work without contact and therefore free of slippage, abrasion and wear. ELOVIS speed gauges are mounted at a safe distance to the conveyor or measurement material and measure the speed of the passing material surface. The sensors are used for machine drive control, for measuring differential speeds between drive and material as well as for the measurement of shrinkage and strain. Speeds are measured on webs, tapes, discrete parts, but also on cylinders and rollers made of a wide variety of materials. The non-contact speed measurement also offers significant accuracy and application advantages over conventional measuring methods at the portable, tripod-based speed measurement, for example for tachometer calibration as well as for the search of errors in the conveyor technology. Several thousand successful installations speak for themselves: “Non-contact Speed Measurement – by the laser-encoder gauges of the μSPEED series from ELOVIS – is user-friendly, handy, robust, reliable and permanently accurate”.

Speed

Measurement

Should the speed of moving web and parts be accurately recorded in order to monitor, control and regulate machines? M...

Measurement of Differential

Speed

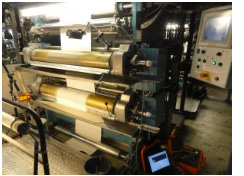

Record differential speed between web, cylinder, conveyor belt or support screen in order to monitor, control and reg...

Speed

Synchronisation

Detect speed of moving surfaces to synchronize aggregates and control and regulate equipment. ... The synchronization...

More

Portable Speed Measurement, Calibration of Speedometers, Displaying

Motion Processes, Speed Measurement of Liquids...

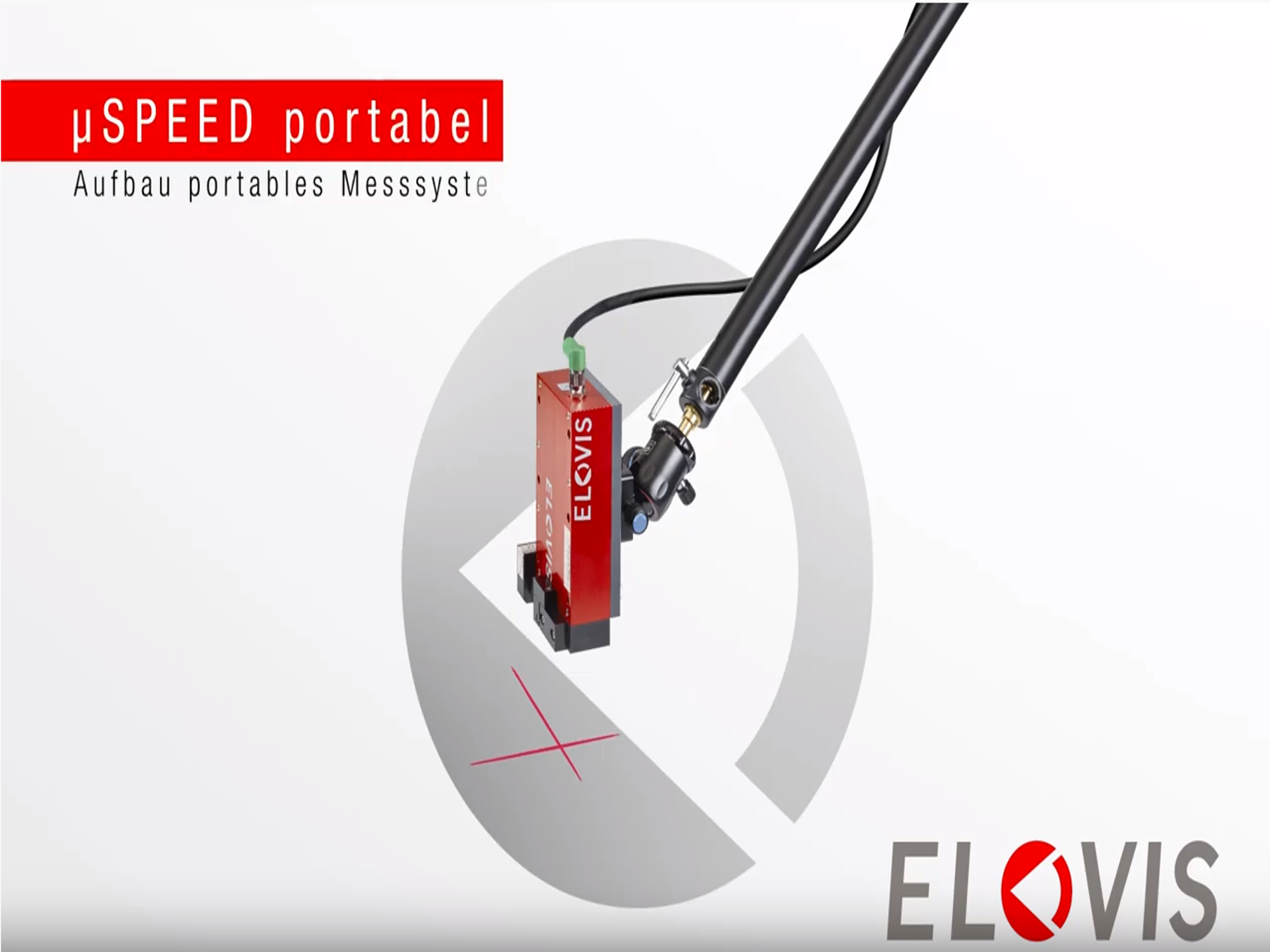

Portable Speed Measurement

Do you want a hand-held measurement device for the risk-free but reliable measurement of speeds? ... The recurrent re...

Calibration of Speedometers

Is your machine regulation based on a theoretical determination of velocities? How can risk-free speedometer calibrat...

Displaying

Motion Processes

Are you interested in the speed profile of a motion process? Do you need measurement values for concentricity, speed ...

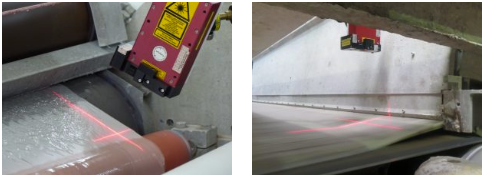

Speed Measurement of Liquids

The measurement of the material jet speed of fourdrinier paper machines is still usually done with indirect measureme...

Milling speed ratio

Looking for an afordable alternative for a degree of stretch control or speed ratio measurement? The measurement devi...

Non-contact speed and motion measurement: The list shows the applications for non-contact ELOVIS speed gauges.

Speed measurement:

Speed measurement on moving webs, tapes, rolls, wraps, bobbins

Measurement of the differential speed:

Parallel speed measurement at several measuring positions for speed comparison

Speed synchronization/speed balancing:

Control of the speeds of different materials or aggregates

Portable / mobile speed measurement:

Portable speed measuring systems in tripod mounting for fast measurement at many different measuring positions

Speedometer calibration:

Speed measuring systems for calibrating tachometers on plants or machines

Logging motion processes:

Detect process speed contactlessly and accurately

Measure the speed of liquids:

Measurement of the speed of liquids and liquid films

Speed ratio control:

Control of cold rolling mills via the differential speed

Non-contact speed and motion measurement: The non-contact ELOVIS speed measurement equipment is listed here. The advantages resulting from the use of these measuring means are subsequently named.

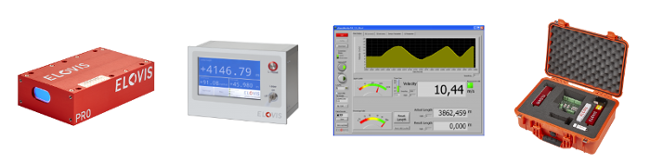

ELOVIS speed measuring equipment, non-contact:

- Laser-Encoder, Laser Tachometer, Laser Doppler Velocimeter, Surface Speed Measurement

µSPEED

Measurement advantages with non-contact ELOVIS measuring instruments:

- Wear-free, maintenance-free, permanently calibrated ⇒ no maintenance costs, low operating costs

- Self-monitoring with early warning system ⇒ failure protection

- Suitable at high speeds ⇒ prepared for the future

- Prevention of contamination ⇒ no carryover of impurities

- Large measurement distance tolerance range ⇒ Thickness-independent measurement

- Measuring principle eliminates the influence of material variation ⇒ Material-independent measurement

- Longlife laser and LED components ⇒ Long measuring life

- Measurement over entire process ⇒ 100% documentation and traceability of measurement results

- Traceable, calibratable, conformity assessable ⇒ Legal certainty

Non-contact speed and motion measurement: Non-contact ELOVIS gauges are used in the following industrial sectors to measure speed and motion.

Production of semi-finished material:

- Paper and board industry (paper raw material, rolls, formats, …)

- Printing and packaging industry (rolls, labels, …)

- Plastic industry (extrusion, profile, hose, pipe, film, film industry, …)

- Textile industry (technical textiles, fabrics, nonwovens, …)

- Carpet and flooring industry (rolls, tiles, …)

- Metal industry (bands, sheets, tubes, profiles, wire, cables, …)

- Cable and wire industry (rolls, spools, packaging, …)

Construction industry:

- Wood industry (veneer, piece wood, boards, …)

- Drywall (slabs, moldings, fittings, …)

- Insulation industry (webs, rolls, plates, …)

Vehicle industry:

- Vehicle industry (route measurement in cars, trucks, rail vehicles, sports vehicles, …)

Touching, tactile speed and motion measurement: The typical traditional and mostly surface touching speed measurement devices are listed here. The measurement problems resulting from the use of these measuring devices are also named here.

Speed Measurement Device, traditional, tactile:

- Measuring wheel, contact wheel, impeller, measuring crawler

- Measurement via drive, drive roller, measuring roller

- Sampling inspection

Measurement problems with traditional measuring equipment:

- Lack of accuracy due to slippage on tactile encoders (Wear, contamination, adhesion problems, accelerations, …)

- Lack of measurement accuracy due to surface dependency with tactile systems (Moisture, strength, softness, roughness, elasticity, …)

- Measurement deviations due to thickness dependence of tactile systems

- Heat problems with tactile systems (hot material)

- Material movement too fast (henceforth only sample inspections)

Consequences of measurement problems:

- Material defects due to incorrect processing / process speeds

- Complaints due to material defects

- High maintenance of tactile measuring equipment

- Material additions to avoid complaints

- Compensation due to lack of transparency and traceability

- Legal uncertainty in European trade

Non-contact speed and motion measurement: List of some application videos of ELOVIS measuring devices in industrial use:

| Product Tutorial – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Tutorial |

|

| Product Video – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Explanation and Application Overview |

|

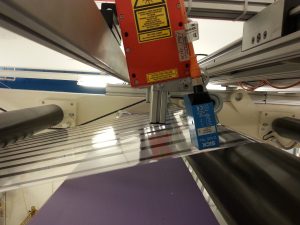

| Repeat Length Measurement – µSPEED-RL

Laser Encoder Length Measurement Systems and Speed Measurement Systems Laser-precise measurement of repeat mark distances in a film printing machine |

|

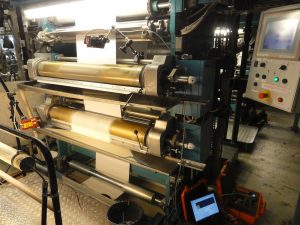

| Differential Speed Measurement in Foil Coating Production – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Measurement on a web and parallel on the coating roller with μSPEED parallel systems |

|

| Paper-Roll Cutter Counter Calibration – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Calibrating the length counter of a winder with a portable μSPEED sensor |

|

| Tenter Frame Shrinkage Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Differential measurement in the goods infeed as well as in the goods outfeed for the determination of the goods advance |

|

| Wire Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in bare-wire production with μSPEED laser system |

|

ELOVIS Services

ELOVIS offers the following services for non-contact speed measurement:

- Consulting regarding speed measurement

- Measurement & calibration services

- System rental and sales of non-contact gauges

- Assistance in dealing with length complaints of your customers