Speed & Length Measurement Technology

In the past weeks we have presented various applications of our measurement systems. As the anniversary campaign is now coming to an end, you will find here once again a short summary of applications and advantages of the sensors. We will continue to grant discounts of up to 25 % for all orders that we receive until the end of the year. This applies to the following systems:

- Laser Encoder of the µSpeed series

- Photoelectric proximity switches of the SLM series

Please do not hesitate to contact us if you have any questions regarding applications in your production or the anniversary offer.

Translated with www.DeepL.com/Translator (free version)

Bernd Engelsdorf

Managing Director

SYSTEMS OF THE µSPEED SERIES:

Typical applications:

- continuous length measurement

- cutting control

- calibration of encoders/tachometers

- differential speed measurement

Typical measurement materials:

- film, foil, paper, cardboard

- textile, nonwoven, fleece, composites

- hose, rubber

- cable, wire…

features:

- typ. measuring accuracy +/- 0,05 %

- contactless and slip-free

- independent of material

- permanently calibrated and maintenance-free

- bidirectional

- mobile use possible

- calibratable according to MID 2014/32/EU

- optional laser protection class 1

SYSTEMS OF THE SLM SERIES:

Typical applications:

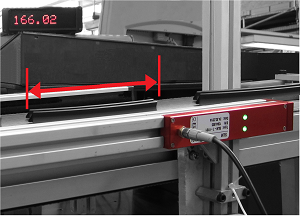

- length control after cut

- inline measurement in throughput

- good/bad sorting

- scrap optimization

- aanual test station

Typical measurement materials:

- profiles

- tubes

- sheets

- plates…

features:

- typ. Measuring accuracy +/- 0.1 mm per m

- independent of material

- permanently calibrated and maintenance-free

- no parameterisation required

- 100% length control/documentation

Application Example 3 dated 2020-11-10:

NON-CONTACT MEASUREMENT OF ROLL AND COIL LENGTH

Is your billing based on correct length values? Are all materials measured with the same accuracy? Or do you risk length complaints?

The exact roll length should be measured during winding of web or spooled goods at high acceleration and high speed. Contact measurement systems, such as friction wheels, measuring wheels or measuring rollers, are subject to slippage and wear. The consequences are uncertainty among customers, length complaints and refunds.

This can be avoided by the use of μSPEED non-contact length measurement systems, which measure independent of material and surface at any speed. ELOVIS laser encoders measure their whole lifetime with constantly high accuracy.

Typical measurement materials:

- film, foil, tarpaulins, membranes

- cable, wire, rope

- paper, cardboard, tissue

- textile, carpet, nonwoven, fabrics

- web material, sheets, foils of metal

- profiles, tubes, hoses, strands

- packaging material of plastic, paper…

The consultation for non-contact length measurement and an evaluation of your recent measurement solution can be done by the ELOVIS-service. Additionally ELOVIS offers rental systems, which help to evaluate the measurement situation for all products over a longer period. Do not hesitate to contact us for your application!

- Interested? Have projects? Have potentials?

- Then … call: 0049 721 / 933 823 – 0

- Or … mail to: info@elovis.de

- Further information and application examples

Application Example 2 dated 2020-10-05:

CALIBRATABLE LENGTH MEASUREMENT

If goods are sold in Europe by length or area, they must usually be measured with “calibrated” length measuring machines, based on the European Measuring Instruments Directive MID 2014/32/EU. The directive stipulates that such length measuring machines must be subjected to a conformity assessment. While buyers of piece goods can usually still check the length of the goods themselves with a tape measure or measuring stick, a buyer of rolled goods, especially of long rolls, can’t do this that easy. For these cases ELOVIS offers measuring systems according to MID 2014/32/EU. In combination with the pre-tested ELOVIS MID-COUNTER, contactless µSPEED systems as well as measuring wheels and measuring beads can be used. With the MID-systems ELOVIS offers the metrological basis for MID-compliant equipment of length measuring machines.

Typical materials which are measured calibratable:

- paper and nonwovens

- Textiles, carpets, felt, geo-textiles

- Cable and wire

- Tubes, hoses, strands

- Films, self-adhesive films, truck tarpaulins

The consultation for MID conformity assessment as well as the assessment of the calibratability of your length measuring machine can also be done as a service by ELOVIS. ELOVIS can also accompany you completely through the conformity assessment process. Just come to us with your MID application!

- Interested? Have projects? Have potentials?

- Then … call: 0049 721 / 933 823 – 0

- Or … mail to: info@elovis.de

- Further information and application examples

Application Example 1 dated 2020-09-14:

CALIBRATION OF LENGTH COUNTERS

The point is to check whether the production length counters work reliably and accurately enough, or whether recalibration or overhaul is necessary. This is to avoid that excess lengths are delivered free of charge or that complaints arise due to the delivery of too short lengths.The mobile calibration of length counters by µSPEED laser encoders is used in many industrial productions.

Whether in the production of web material, such as Foils, film, paper, nonwovens, textiles and composites or in the production and packaging of strand and roll goods, e.g. Profiles, wire, cable, pipe, hose.

µSPEED laser encoders are set up fast, safely and stable in parallel with running production using a tripod and an optical adjustment device. Displaying the measurement values, measurement evaluation and data storage are carried out using ELOVIS PC software.

Calibration can be done by ELOVIS Service, or by the use of rental or purchase systems. A video tutorial makes commissioning and use of µSPEED extremely easy.

- Interested? Have projects? Have potentials?

- Then … call: 0049 721 / 933 823 – 0

- Or … mail to: info@elovis.de

- Further information and application examples