Measure in Throughput – sort, regulate, document

Are you interrupting your production or reducing the throughput speed to check lengths manually? Sample test costs productivity and involves risks. In automated, contact based measurement procedures, incoming and outgoing material edges lead to increased wear and deviations in measurement. Movement against stops costs processing time and can damage measurement goods. One solution is non-contact length measurement systems, which neither disturb the process nor are subject to wear. ELOVIS recommends an accuracy in the millimeter range for the final measurement of part lengths up to 20m, or for even larger piece lengths μSPEED Laser-Encoder. For measurements in the 1/10 mm accuracy range and up to the current 5m measuring length, the use of the SLM length section light scanner technology is recommended. The non-contact final measurement of the part lengths is carried out with both sensors, μSPEED as well as the SLM gauge during moving measured goods in longitudinal direction. The measurement serves the good / bad sorting as well as the documentation of the delivery status. μSPEED and SLM gauges for non-contact part length measurement are used to measure profiles, tubes, plates, beams, bolts, struts, rails, hubs made of a wide variety of materials.

Typical materials:

- Plastic and extrusion (profiles, hoses, pipes …)

- Metal (profiles, tubes, rods, beams, rails …)

- Cable, wire

- Plastic plates and foil formats

- Metal (sheets, blanks, bows, …)

- Construction and insulation materials (plasterboard and fiberboard, …)

- Wood (firewood, KVH, beams, …)

- Chipboard (MDF boards, HDF boards, OSB boards)

- Rubber plates

Typical machines with problems in the piece length measurement as well as machines and machine elements for the production of piece goods, sawing parts, cut goods:

- Guillotine

- Cross Cutter

- Lateral Divider

- Cutting machine

- Sawing line, flying saw

- Throughfeed saw

- Punch

- Parting line

- Trimming line

Application Examples

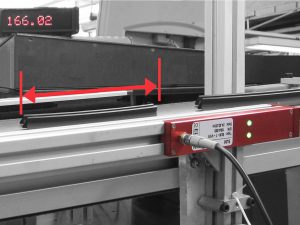

Length Measurement of Pipe Pieces and Profile Pieces

So far, pipes and profiles have only been randomly inspected for correct lengths after sawing. With the μSPEED gauge,...

Measure lengths of pieces of wood, beams and plates

Solid construction wood, wooden beams, boards, plates made of MDF, HDF, OSB, ... are mostly checked by hand after saw...

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

ELOVIS Services

ELOVIS offer the following services in the area of discrete part length measurement:

- Advice on discrete part length measurement

- Measurement and calibration services

- Assistance in finding system malfunctions

- OEM sensor developments in the field of part length measurement