dimensional control of furniture plates, chipboard, sheets, panels, boards, packages

If several dimensions of semi-finished products have to be checked to secure subsequent processes, combined measurement solutions from a single source are the first choice. If lengths, widths, heights, thicknesses of semi-finished products are checked by hand and in random samples, the test is not only personnel-intensive and person-dependent but in many cases even critical under the aspect of work safety and increasingly inadmissible. The solution is a combination of non-contact length and cross-section light scanners, if necessary supplemented by additional 2D and 3D sensors that perform their work without interrupting the process, while the measured objects pass through, in a stable, user-independent and highly accurate manner. The dimensional check is used to detect incorrect parts, tolerance violation and documentation of the manufacturing or delivery quality status. Measuring solutions from ELOVIS are used for non-contact length, width, height and thickness measurement of plates, packages, pallet stacks, rolls, beams and rods made of a wide variety of materials.

Typical measurement objects:

- Furniture panels and wood panels

- Particleboard, OSB boards, HDF, MDF

- Wooden workpieces, beams, boards

- Sheets, sheets, plates, plates of metal

- Packages and cartons pallet loads

- Paper rolls, rolls of film, rolls of nonwoven and textile or carpet

Machines requiring a dimensional control:

- Continuous processing machines for edge processing, trimming, surface treatment, painting, …

- Conveyor line after cross cutters

- Logistics centers with package conveyor lines or pallet conveyor lines

- Storage systems for paper rolls, film rolls, textile, nonwoven, carpet

Applicartion Examples

Dimensional Check of Furniture Panels

Are you looking for a measurement solution for automatic, exact length and width control in the production of furnitu...

Dimensional check on sheet metals and circuit boards

Dimensional control in sheet metal and panel production requires a robust, accurate, if possible non-contact, gauging...

Pack size and packages, volume measurement

Are you looking for a measurement solution for automatic volume measurement in the logistics and packaging industry. ...

Matching Products and Services

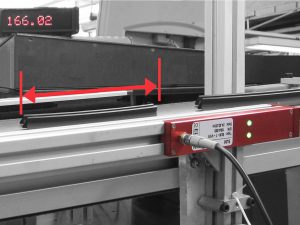

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

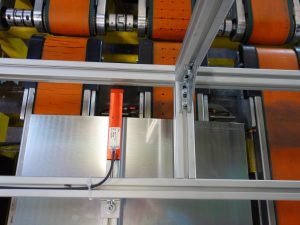

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offer the following services in this area:

- Advice on combined non-contact length, width, height, diameter measurement

- Measurement services Measurement

- System Rent

- Assistance in finding system malfunctions

- OEM sensor developments in the field of combined length, width, height and diameter measurement