Measurement of length, width, thickness on sheet metals, panels, circuit boards

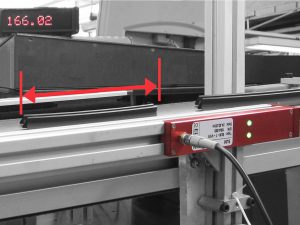

Dimensional control in sheet metal and panel production requires a robust, accurate, if possible non-contact, gauging solution. ELOVIS combines proven serial single sensors into a solution for 100% inspection of sheet metals, panels and circuit boards in the ongoing production process. This is done with a measurement accuracy of up to 0.5 mm for plates up to 7500 mm in length, 2500 mm in width and speeds up to 120 m / min. The dimensional control is used to detect incorrect parts, tolerance violation and the documentation of the manufacturing or delivery quality status. The combined dimensional control systems from ELOVIS are used for measuring length, width, height and thickness of metal plates, sheet metals, panels and circuit boards.

Typical Application Data:

- Measurement parameters are length, width, thickness

- Modular concept enables inline as well as offline measurement

- Production speeds: typically up to 240 m / min

- Measuring accuracy: typically 0.1 mm per meter

- Offline system prepared for the conversion of measurement data into CAD / CAM data

- amortization: 2-3 months; If necessary, integration of the measuring system into the existing system technology

Material examples:

- Metal plates, sheet metals

- Panels, circuit boards

- Made of steel, aluminum, copper, bronze, alloys, stainless steel, …

Machines equipped with non-contact cross-section measurement:

- Cross Cutter

- Stamps

- Trimming lines, edging lines

- Coating lines

- Painting lines

Matching Products and Services

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offers the following services for the measurement of widths, heights, diameters:

- Advice on cross-section measurement

- measurement services

- Help with complaints from your customers

- OEM sensor developments in the field of cross-section measurement