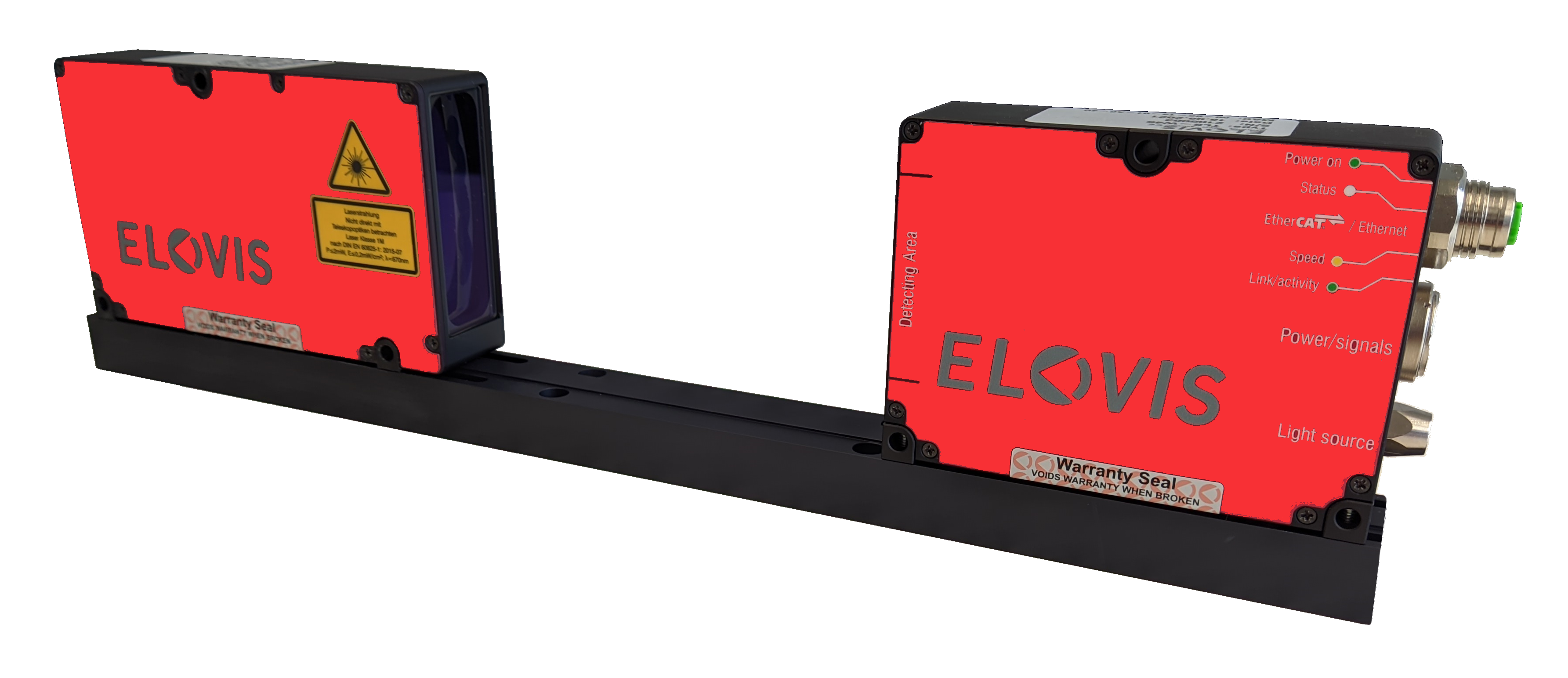

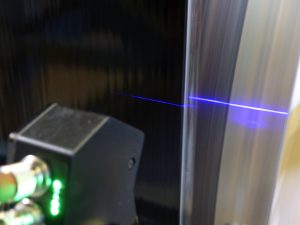

Optical Micrometer for determining edge distances cross to the transport direction

The width height diameter measurement systems μMETER-X of ELOVIS are used for non-contact cross-section measurement of profiles, strip goods and discrete parts in the production process, during conveying movement in the longitudinal direction. The highly accurate measurement in the light scanner generally serves production monitoring, process optimization and documentation of the delivery status of all manufactured goods. μMETER-X systems use light reflection or transmitted light. μMETER-X systems are maintenance-free, permanently calibrated and measure largely independent of the material. As a kind of “optical caliper”, μMETER-X systems are used for cross-section measurement, profile measurement as well as measurement of width, height, diameter … of web, tape, profiles, tube, plate, board, beam, bolt and roller made out of different materials.

Product Types – Cross-Section Light Scanner – Width Height Diameter Measurement Systems

µMETER-X-TLSSystem for high-precision measurement of width, height, diameter, gap, position, edge distance and segments

|

|

µMETER-X-VIS/3DWidth, Height, Diameter Measurement Systems with 3D signal evaluation:

|

|

µMETER-X-VIS/2DWidth Height Diameter Measurement Systems with 2D Signal Evaluation:

|

|

Cross-Section Light Scanner – Width Height Diameter Measurement Systems

Optical Micrometer / Measuring Cross-Section Light Scanner – in Production Process

| µMETER-X: | TLS-Wx | VIS/3D-Wx | VIS/2D-Wx |

| System Components | Transmitted light scanner (transmitter and receiver) | 3D Vision-System | 2D Vision-System |

| Product Types | different measuring field sizes | different measurement field sizes | different measurement field sizes |

| Measurement Field (Width) | 45 mm and 95 mm | 3 mm to 1.250 mm | 0,3 mm to 875 mm |

| Measurement Field (Depth) | 100 mm up to 1900 mm | 80 mm to 2.000 mm | – |

| Measurement Resolution | 1 µm (Linearity: +/- 10 µm) | typically: width: ± 0,05 mm to ± 0,9 mm depth: ± 0,01 mm to ± 0,5 mm |

typically: only width: ± 0,03 mm bis ± 1 mm |

| Repeatability | < 5 µm | depending on system ± 0,01 % to ± 0,5 % (confidence interval 1σ) | |

| Arrangement of the Sensor System | horizontally, vertically or also diagonally | horizontal, vertical or diagonal | horizontal, vertical or diagonal |

| Measurement Frequency | up to 2500 Hz | up to 1000 Hz | up to 500 Hz |

| Measurement Distance between Gauge and Measurement Object | 20 mm to 150 mm | 150 mm to 2.500 mm | 150 mm to 500 mm |

| Interfaces | Ethernet/EtherCAT | Ethernet/EtherCAT | 1 x RS-485 |

| I/Os | Input: Trigger Output: Sync |

Input: Start, Calibration Output: Status |

|

| I/O Type | not galvanically isolated 24 V logic (HTL), high level dependent on operating voltage | RS‐422 Gauge | |

| Available Data | Measured values, status | Measurement values, signal quality, status, valid measurement | |

| Fieldbus | Optional:

Profibus-DP, ProfiNet-RT, Ethernet-IP |

Optional:

Profibus-DP, ProfiNet‐RT, Ethernet‐IP, … |

|

| Protection Class | IP64 | IP50 | IP67 |

| Dimensions (LxWxH) |

depending on maximum measuring field size | depending on maximum measurement field size | |

| Power Supply | 24 VDC (11 … 30 VDC) | 12 – 24 VDC | |

| Weight | up tp 2,5 kg | depending on maximum measurement field size | |

| Light Wavelength and Category | 1M, 670 nm (red) – according to DIN EN 60825-1 : 2015-07 | Class 2, <100mW average, wave length 450nm | 1 mW up to 20 mW Infrared |

| Ambient Temperature | 0 to 50°C – non-condensing, outside temperature range external cooling / heating required | 0 to 50°C ‐ not condensing, beyond of temperature range external cooling/heating required | |

| Humidity | Environment should be dry, no condensation | Environment should be dry, no condensation | |

Cross-Section Light Scanner – Width Heigth Diameter Measurement Systems

Optical Micrometer / Measuring Cross-Section Light Scanner – In Production

Standard Interface |

|

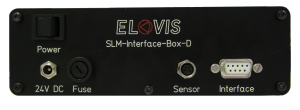

Interface Box for PC Operation µMETER-X-BOX |

Interface box for connecting the sensor to a PC or laptop. Allows for easy connection and supply of the sensor. With RS485 output interface and plug-in power supply. |

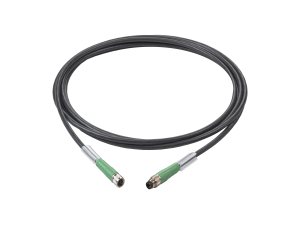

Sensor Cable |

| Shielded Cables

µMETER-X-K3, K10 |

Sensor cable for connection to an interface such as µMETER-X-Box or bus module, a controller or a display. |  |

Displays and Control Units |

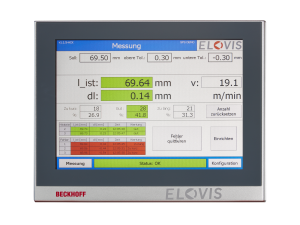

| Display of Measurement Values

µMETER-X-DISPLAY-BOX |

Interface box with measurement value display for connecting the sensor system to a PC or laptop. Box with RS485 output interface and plug-in power supply. | |

| Control/Control Unit

µMETER-X-CONTROLLER |

Display and Control Unit for the sensors provide the following features:

|

|

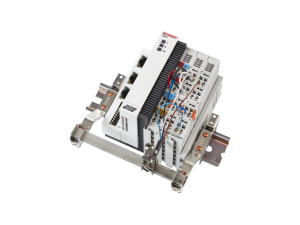

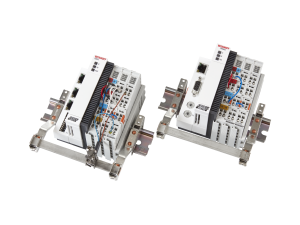

| Sorting Control

µMETER-X-SPS |

The SPS sorting control for the µMETER-X sensors provide the following features:

|

Mobile Equipment |

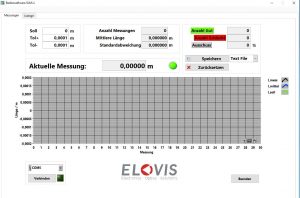

Software |

Fieldbus and Communication Modules |

| Profibus-DP, ProfiNet-RT, Ethernet-IP

µMETER-XPB, -PN, -EN |

Standard bus interface modules with the following output: Measurement Value (in m) , Speed (in m/s), Status Signal (valid/invalid) |

Cross-Section Light Scanner for Width Height Diameter Measurement

The material to be measured passes through the measurement area across the conveying direction of the µMETER-X System in longitudinal direction. As soon as the material is located on the same height as the sensor, the corresponding cross-sectional dimension is automatically and continuously determined. To ensure that the measurement can take place with high accuracy, the measurement material has to be as clean and dry as possible. In addition, the measurement object should pass the µMETER-X system as straight as possible. The measurement principle can be described as optical micrometer / measuring cross-section light scanner for measurements in the production cycle. The µVIS-3D system is based on a laser light-section concept in incident light. But the µVIS-3D system can also process transmitted light information. The µVIS-2D system is based on shading of a reflector by the measuring material.

Videos about Cross-Section Light Scanner – Width Height Diameter Measurement Systems

Optical Micrometer / Measuring Cross-Section Light Scanner – in Production Process

Optical Micrometer / Measuring Cross-Section Light Scanner – in

Product Video

Application Video

Downloads for Cross-Section Light Scanner – Width Height Diameter Measurement Systems

Optical Micrometer / Measuring Cross-Section Light Scanner – in Production Process

Product Brochure µMETER-X-V3D -> please contact ELOVIS

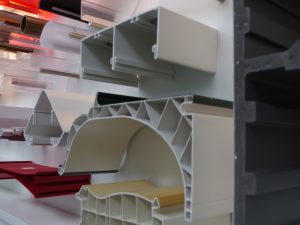

APPLICATIONS

Width, height, diameter

of profiles

Do you measure the widths and heights of profiles in random samples, because optical micrometers can only cope with p...

Widths Measurement of webs, strips and boards

Widths of webs, tapes and plates are usually measured by hand in random sample inspections because contact measuremen...

Width Height Edge

Distances in Incident Light

The measurement situation prevents the use of a transmitted-light system for the measurement of widths and heights or...

Measure Free-Forms

and Profiles 2D / 3D

You want to measure geometries on flat free-forms in two dimensions or on free-form surfaces in three dimensions? ......

APPLICATION EXAMPLES

Dimension of extrusion profiles

The early knowledge of the profile dimensions, such as height, width, gap dimensions, ... helps to timely counteract ...

Width measurement of bitumen membranes and roofing membranes

Bituminous sheeting and roofing membranes are to be tested for correct width in production. Width errors that already...

Width and thickness for narrow web/strap

Strapping, web or belt should be checked for correct width and correct thickness. Width and thickness errors that alr...