Repeat Length Measurement – highly precise at maximum speed

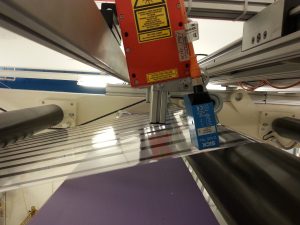

The purpose of pattern repeat length measurement is to shorten the running-in process and to achieve permanently correct mark distances. When product elasticities and machine drives have to be matched, and when mark distances must be in a tolerance range defined by the customer, the printers and process engineers are demanded. Without tools and relying just on feeling, the adjustment work can be time-consuming and wasteful. … Whether measurement for documentation purposes, from process monitoring to process control, the laser-encoder based pattern repeat-length measurement systems μSPEED-RL are non-contact and consistantly accurate measurement solutions.

Typical imprinted measurement materials:

- Paper, Cardboard, Tissue, …

- Film, foil, plastic packaging

- Textiles, carpets, nonwoven, fabric

- Webs, sheets, foils of metal

- Cable, wire, rope

- Profiles, tubes, strands

Typical machines with measurement problems:

- Printing machines

- Web printing machines

- Rewinder

- Doctor Roller

- Inkjet printers

- Laser marking systems

Application Examples

Repeat Length

Measurement System

Monitoring of the pattern repeat lengths is crucial for a printer. Tension of the machines and the stretchability of ...

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services in the field of pattern repeat length measurement:

- Advice on mark distance measurement

- Measurement and calibration services

- Assistance in finding system malfunctions

- OEM sensor developments in the field of pattern repeat length measurement