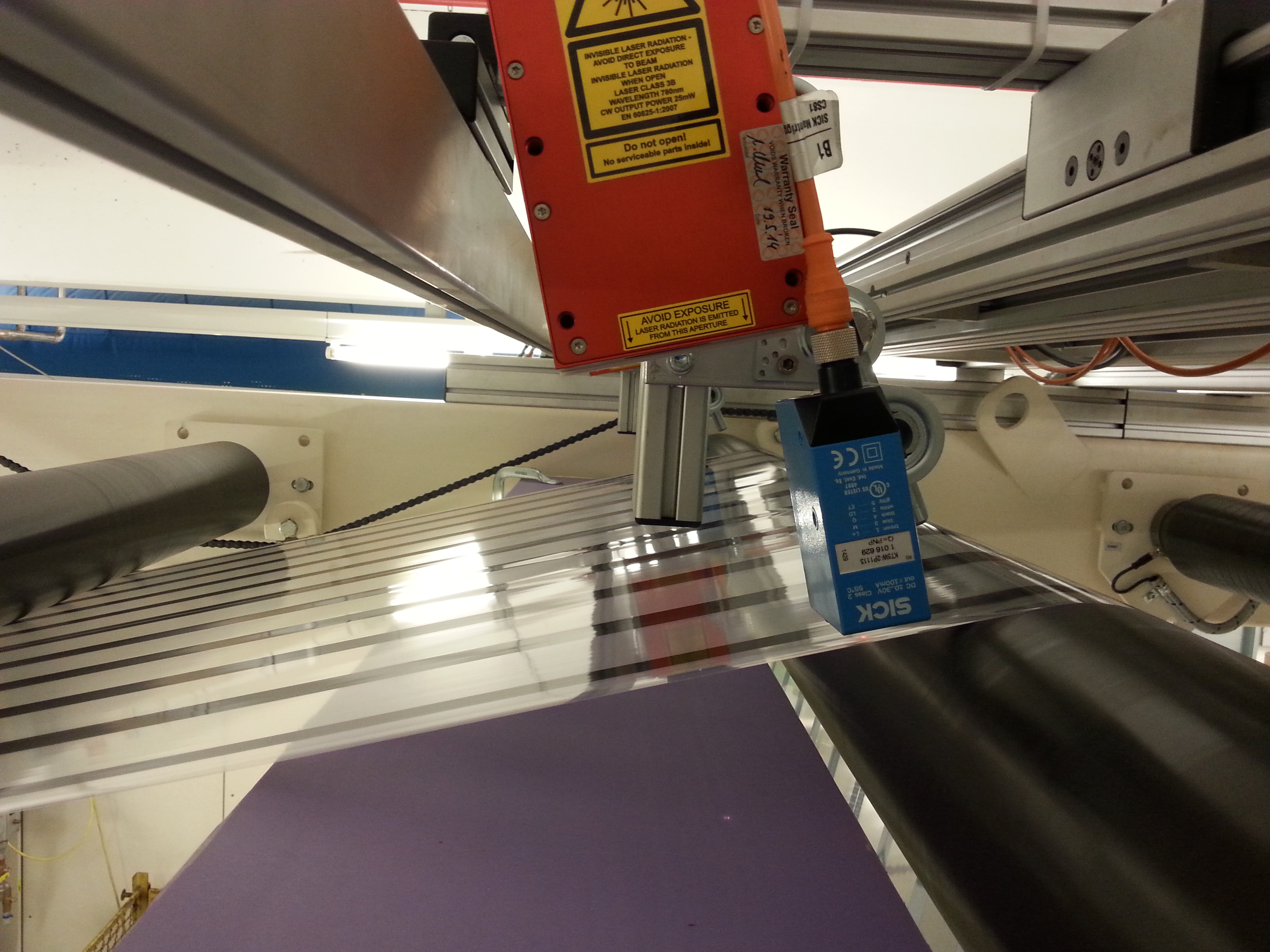

Measurement of mark distances in the printing press

Monitoring of the pattern repeat lengths is crucial for a printer. Tension of the machines and the stretchability of the material makes it difficult to meet the requirements for correct mark distances. The ELOVIS Laser-Encoder system μSPEED-RL system offers non-contact and continuous accurate inline measurement from the first meters.

Typical application data:

- Path Velocity: typically up to 1,800 m / min

- Mark spacing: typically from 50 mm to 1,000 mm

- Measurement accuracy with repeat length measuring system μSPEED-RL: typically +/- 0.3 mm

- Amortization: 3 months, optional: integration in machine control

Material examples:

- transparent film, high-gloss film, food film, packaging film, furniture film, …

- PET film, PE film, PP film, PVC film, PS film, PLA film, …

Machines equipped with non-contact length measurement:

- Printing machine, roll printing press

- roll cutting machine, roll cutter, cross cutter, lengthwise cutter

- Winding machines, rewinder, re-roller, doctor roller

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services for repeat length measurement:

- Advice on pattern repeat length measurement

- Measurement & calibration services

- Help with brand-name complaints from your customers

- OEM sensor developments in the field of printing mark distance measurement