complete dimensional checks of profile, tube production and extrusion lines

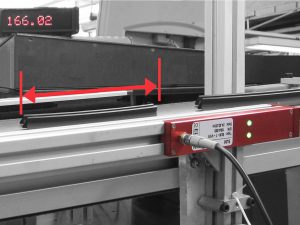

In the production of profiles, hoses and pipes, it is important to comply with different tolerances and to optimize or regulate the process with inline measurement values. If lengths, diameters, gap sizes of such semi-finished products are checked by hand and random sample inspection, the test is not only labor-intensive and person-dependent but in many cases even critical under the aspect of work safety and increasingly inadmissible. The solution is combined of non-contact laser doppler systems, length- and cross-section light scanners possibly supplemented by other 2D and 3D sensors that perform their work without interrupting the process, normally during regular transportation of the measurement objects, stable, user-independent and highly accurate. The dimensional control is used to detect incorrect parts, tolerance violation and for the documentation of the manufacturing or delivery quality status. Dimensional control systems from ELOVIS are used to measure profiles, seals, hoses, pipes made of a wide variety of materials.

Typical measurement objects:

- Extrusion Profiles

- Extrusion Moulding Profiles

- Sealing Profiles

- Hoses

- Medical Tubes

- Hydraulic Hoses

- Plastic Pipes

- Metal Pipes

- Bolts, Ingots

Machines requiring a dimensional check:

- Extrusion lines with guillotines and flying scissors

- Extruded profile lines with and without sawing

- Conveyor line after cross cutters, knives and punches

- Continuous processing machines for edge processing, trimming, surface treatment, painting, …

Application Examples

Matching Products and Services

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offers the following services in this area:

- Advice on non-contact width-height diameter measurement

- measurement services

- Measurement System Rent

- Help in finding system malfunctions

- OEM sensor developments in width-height diameter measurement