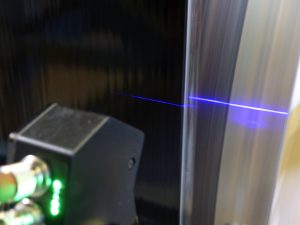

measurement during material movement, cross to the feeding direction

Widths of webs, tapes and plates are usually measured by hand in random sample inspections because contact measurement devices damage the products or because non-contact measurement devices are too costly. … In the production of webs, belts and plates, the edge trimming and the lengthswise cutters are adjusted at the beginning of the process. This is followed by a manual control of the width. In the ongoing manufacturing process, dimensions are generally no longer checked. A check can only be done again on the finished product, the roll of material or the plate. If deviations occur, the entire roll or a batch is declared as a waste. … The solution is a non-contact gauge that is easy to integrate and does not disrupt the regular production process. ELOVIS offers the µMETER-X systems for the measurement of webs, tapes and plates with widths up to the current 2000 mm and with an accuracy in the 1/10 millimeter range. The non-contact measurement is carried out by the µMETER-X gauge during the product cycle in cross feeding direction. The measurement is used for production optimization as well as for sending an error message in case of exceeding production tolerances and it is used for the documentation of the production quality. µMETER-X gauges are maintenance-free, permanently accurate and measure widely independent of material. µMETER-X gauges are used to measure the width of webs, tapes, plates, sheets, blanks, bolts, bars, beams or packages made of a wide variety of materials.

Typical measurement objects using non-contact width measurement:

Plates, boards, formats, such as:

- plastic sheets and foil formats

- metal (sheets, blanks, bows, …)

- construction and insulation materials (plasterboard and fiberboard, …)

- wood (firewood, KVH, beams, …)

- chipboards (MDF boards, HDF boards, OSB boards)

- furniture panels (MFB melamine-coated panels, printed panels, lacquered furniture panels, …)

- floor coverings, tiles, carpet tiles

Webs, tapes, strips and ribbons, such as:

- bituminous membranes, roofing membranes

- paper, cardboard, packaging webs

- foils, printed / unprinted, made of plastic, aluminum, composite material

- textile, non-woven, fleece, felt

- separator foils, battery foils

- strippings

Typical production machines that can be optimized with a width measurement:

Machines for the production of plate goods:

- guillotine, sheeter, cross divider

- cutting machine, sawing line

- flying saw, continuous saw

- punch, dividing line, trimming line

Machines for the production of web products and tapes:

- slitter, sheeter

- winding machines, rewinders

- slitter

- fabric inspection machine

- calendering machines

- laminating machines

Application Examples

Width measurement of bitumen membranes and roofing membranes

Bituminous sheeting and roofing membranes are to be tested for correct width in production. Width errors that already...

Width and thickness for narrow web/strap

Strapping, web or belt should be checked for correct width and correct thickness. Width and thickness errors that alr...

Matching Products and Services

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offers the following services in this area:

- Consultation for non-contact width measurement

- measurement services

- Measurement System Rent

- Help in finding system malfunctions

- OEM sensor developments in the field of gauge measurement of plates, webs, ribbons