Slip, shrinkage and strain measurement as well as process control

Record differential speed between web, cylinder, conveyor belt or support screen in order to monitor, control and regulate systems. Due to slippage, material, surface and thickness dependencies, tactile measuring systems do not offer sufficiently high measuring accuracy. Hand-held tactile measuring equipment also represents a considerable risk of injury in portable use. Therefore, sensors are needed which are simple and quick to use without danger, which measure accurately on all surfaces, structures and colors without the need for parameterization, regardless of whether the material to be measured is tight, soft, dry or damp and whether it is to be measured on tapes, webs, on rollers, cylinders or screens. Applications extend from portable use to determining differential speeds at multiple measurement points in production facilities, to drive monitoring, tachometer calibration, plant control, and process optimization to detect shrinkage and strain.

Typical measurement materials:

- Paper, cardboard, tissue to cylinder

- Pulpjet, headbox for screen speed

- Film, foil, plastic packaging

- Textiles, carpets, nonwoven, nonwoven fabric

- webs, foils of metal

- Cable, wire in inlet and outlet

- Extrusion material such as profiles, hoses

- Rolling material, strips, sheets

Typical machines with measurement problems:

- Paper machines, long wire machines, headbox

- Winder, slitter, rewinder

- Tenter frame, stenter frame in inlet and outlet

- Dryer in inlet and outlet

- calendering machines

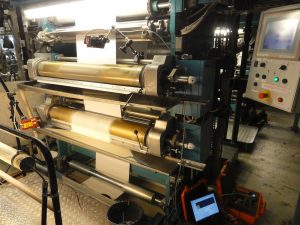

- laminating machines

- coating machines

- Rolling machines for measuring the degree of yield

Application Examples

Differential V between Drive and Material

Machine drives and material should be moved with the lowest possible differential speed. Ensuring this is not easy an...

Measurement of Speed Differences in the Headbox of a Paper Machine

The paper quality is often already determined in the headbox of a paper machine. The appropriate ratio between wire s...

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services regarding speed measurement:

- Consulting for non-contact speed measurement

- Measurement & Calibration Services

- Help in finding system malfunctions

- OEM sensor development in the area of non-contact speed measurement