Differences in between Paper-Wire and Head-box Speed

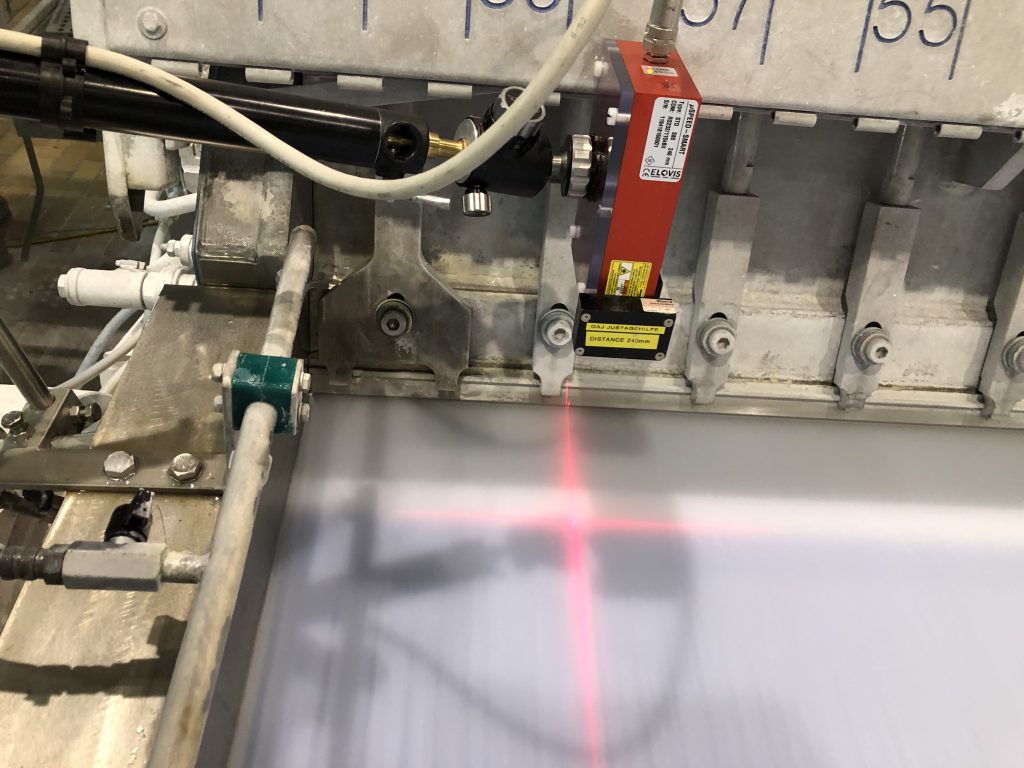

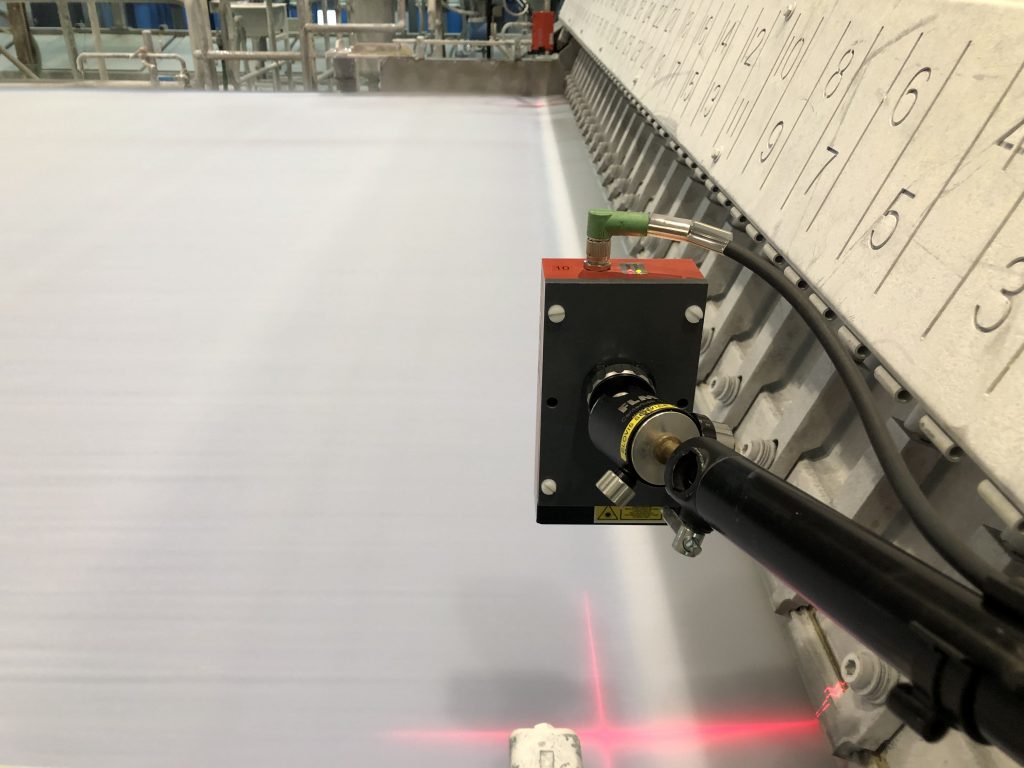

The paper quality is often already determined in the headbox of a paper machine. The appropriate ratio between wire speed and jet beam velocity must be maintained, but the pulp jet velocity should be as homogeneous as possible within the headbox. Therefore, there should be no or only very small speed differences. It is not easy to ensure this and it is not possible to check speed differences with tactile measuring equipment. µSPEED laser encoder systems work contactless and are even suitable for this measuring application, so for measuring differences between paper wire and stock steel or within the headbox. Therefore µSPEED systems are an important tool for trouble shooting in paper production!

Typical Application Data:

- Paper wire speed and stock jet speed: typically up to 2,400 m/min

- Since then: Measurement of the paper wire speed via the wire drive and estimation of the pulp jet speed via the pressure conditions in the headbox

- Measurement accuracy with non-contact length measurement µSPEED: typical: 0.1 %

- Measurement setup: µSPEED laser encoder, PC for measured value display and storage, tripod mounting

- Amortization: typically 1 month

Measurement / Material Examples:

- Wire speed or paper wire speed in paper machines

- Speed of conveyor belts, screens, felts in alignment with drive speeds

- Material speed of pulp, pulp jet, paper, nonwoven, fleece

- Speed of cylinders, rollers, Poperoller, Tambour

Machines equipped with non-contact length measurement:

- Paper Machines, Card-Board machines

- Tissue Machines, Crepe formers, Yankee cylinders

- Nonwoven and nonwoven machines

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services for speed measurement:

- Advice on speed measurement

- Measurement & calibration services

- Help with system malfunctions

- OEM sensor developments in the field of length and speed measurement