Length Counter with measuring wheel encoder and parts certificate according to MID 2014/32/EU

The ELOVIS MID-COUNTER complies with the requirements of the European Measuring Instruments Directive MID 2014/32 / EU and has a parts certificate even as length counter with measuring wheel encoder. The ELOVIS MID-COUNTER is equipped with a long-term memory that safely stores more than 4 million measurement results. The MID COUNTER also provides control functions, such as preselection length, pre-contact, cut/stop contact, additional functions, such as good/bad length counter; transmission correction factor; calibration; Connection of a label printer. The MID-COUNTER is network-compatible and provides interfaces for connection to the customer’s own production data acquisition (PDA).

Product Types for length counters with measuring wheel encoder and parts certificate according to MID 2014/32/EU

Technical Data – Length Counter with measuring wheel encoder and parts certificate acc. to MID 2014/32/EU

| MID-COUNTER with MID-WE |

|

| Conformity Assessment Procedure | MID 2014/32/EU pre-examination and part unit certificate available |

| Direction Recognition | Yes, contact |

| Measurement from V=0 | Yes, contact |

| Accuracy (typ.) (2σ;L>10m/3σ;L>20m) |

ca. ± 0,3 % Accuracy Class III |

| Repeatability | ± 0,1 % of measurement value |

| Type of Sensor/Device | Measuring Wheel Encoder with Counter |

| V-Measurement Range | 0 m/min → 300 m/min (5 m/s) 0 m/min → ± 900 ft/min (± 15 ft/s) |

| Measurement Distance (Tolerances) | tactile, contacting measurement |

| Interfaces | 2 x RS-232 USB 2.0 Device (PC Connection) 10/100 MBit Ethernet interface |

| I/Os | Quadrature Output 1 to 100.000 (depending on maximum speed) pls/m Input: 4 x digital Output: 4 x digital |

| I/O Type | RS‐422 Gauge Laser Interlock (single, 24V) |

| Available Data | Speed, Length, Laser Interlock, Valid Measurement Data Storage: Storage of > 4 million measurement values |

| Network/Database Connection | Available Protocols: SOAP, XML, JSON, UPD transmitted with every reset: serial number, measurement ID, meter, status optional transmission: date, time, pre-settings, order number |

| Protection Class | Sensor Head: acc. to type (smooth running types: IP65, IP66) MID-COUNTER: Front: IP51; Back: IP20 |

| Dimensions (LxWxH) |

Measuring Wheel: depending on diameter |

| Power Supply | 24VDC (18 V to 24 V) |

| Weight | Measuring Wheel: depending on diameter |

| Ambient Temperature/Humidity | 5 to 45°C ‐ not condensing Beyond normal temperature range: external cooling/heating system required. |

Accessories for MID 2014/32/EU Calibratable Length Measurement Systems tactile / non-contact

Sensor Cable |

| Shielded Cables

µSPEED-C10, C25, C50 |

Sensor cables for connecting the µSPEED sensors with the MID-COUNTER with lengths between 10 and 50 m (longer lengths on demand) |  |

Display and Control Units |

Label Printer |

Optical Adjustment Monitoring |

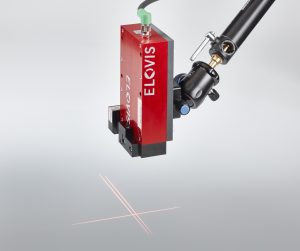

| Optical Adjustment Aid

µSPEED-OAJ-3-N |

μSPEED-OAJ-3-N allows a fast and safe adjustment of μSPEED systems without the aid of meter sticks, spirit level or protractor. The adjustment aid OAJ3 is, among other things, for portable measurement applications, for measurements on rotating cylinders or in tight spaces and in applications with constantly varying material spacing. |

Protection Casing |

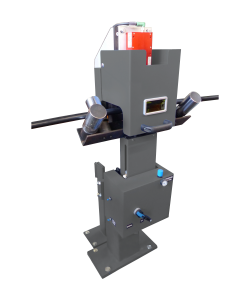

| Casing for air cooling

µSPEED-HSEe |

The casing μSPEED-HSEe made of stainless steel is used to protect the sensor head from contamination and from unsuitable ambient temperatures. The HSEe must be supplied with suitable purging air. | |

| Casing for air cooling and water cooling

µSPEED-HSEw |

The casing μSPEED-HSEw is used to protect the sensor head from contamination and from unsuitable ambient temperatures. The HSEw must be supplied with suitable purging air. It is designed for higher ambient temperatures due to the additional connection for water cooling. The HSEw contains two heat exchanger plates. | |

| Heat Exchanger Plates

µSPEED-HE |

Heat exchanger plates with 2 cooling water flange connections can be mounted on one or both sides of the sensor head. The water-rinsed heat exchanger plates allow the use of the sensor in a warm measuring environment. | |

| Quick Cange Protective Glass

µSPEED-QCW |

The μSPEED-QCW Quick Change Protective Glass is designed for use in harsh environments with heavily polluted ambient air. The QCW allows the replacement of the protective glass in seconds and allows the actual cleaning of the glass can be operated detached from the sensor. |

Sensor Mounting Plate |

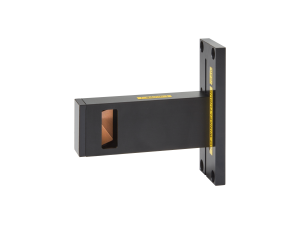

| Mounting Plate with Swivel/Slot Hole Element

µSPEED-MP |

μSPEED-MP is set up via rotary element, which allows an angular adjustment of the sensor in the material movement direction by +/- 80 °. Slotted holes on the rotary element allow a distance adjustment of the sensor head. |

Height Adjustment Unit |

Cable Guidance with Stand |

Laser Protection Equipment |

Length Counter with Measuring Wheel Encoder and Parts Certificate acc. to MID 2014/32/EU

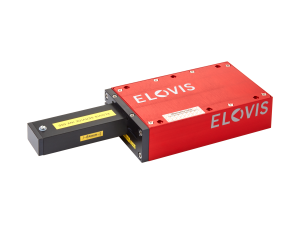

MID 2014/32/EU Tactile Calibratable Length Measurement

A measuring wheel runs along the medium to be measured. The measuring wheel is driven by the measurement object itself. The measuring wheel is mechanically connected to the machine and is held by a spring arm via the spring preload on the material to be measured. The encoder flanged to the measuring wheel sends a quadrature signal to the MID-COUNTER, which processes the signal and determines length values.

The basis for a good function and accuracy is a slip-free contact between the friction wheel and the measurement surface. Not all measurement surfaces are suitable for tactile measuring wheel scanning. In these cases, we recommend the use of non-contact laser encoders type μSPEED, which are also used in connection with the MID-COUNTER acc. European Measuring Instruments Directive MID 2014/32 / EU.

Videos regarding MID 2014/32/EU Calibratable Length Measurement Systems tactile / non-contact

| Product Video – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Product Ranges and Application Overview |

|

| Length Measurement in Textile Production – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Measurement at the output of production with portable μSPEED system |

|

| Wire Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in bare-wire production with μSPEED laser system |

|

| Steel Rope Length Measurement System – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Testing the measurement accuracy of a system counter for ropes with portable μSPEED laser sensor |

|

| Textile Fabric Inspection Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement machine for textiles is calibrated without contact with μSPEED |

|

| Nonwoven Fabric Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in nonwoven fabric production plant without contact with μSPEED laser doppler system |

|

APPLICATIONS

MID certified Length Measurement

If goods are sold in Europe by length or area, they generally must be measured with "MID-certified" calibrated length...

Roll Length/Coil Length

Is your billing based on correct length values? Are all materials measured with same accuracy? Or do you risk len...

Cut-to-length Control

Do you avoid length additions or do you deliver excess length just to be safe? Do you have the strict requirement to ...

APPLICATION EXAMPLES

Certified fabric inspection for textiles

Textiles, fabrics, artificial leather, laminated materials are sold by length and must therefore be measured on calib...

Calibrated Length Measurement of Cables

Cables are usually sold on rolls according to length and must therefore be measured with calibrated length measuremen...

Calibrated Measurement of Paper and Fleece

When selling paper and nonwovens in the EU, the length or area measurement must be done with calibrated length measur...

MAAG Rolling Measuring Inspection Machine

MAAG inspection machines for the final presentation with contactless calibrated length measurement acc. MID 2014/32 /...

ETF carpet cutting and length measuring machines

ETF slitting machines and length measuring machines for the carpet and non-woven industry are offered with non-contac...