Final Measurement of Parts, Good/Waste Sorting, Documentation of the Production

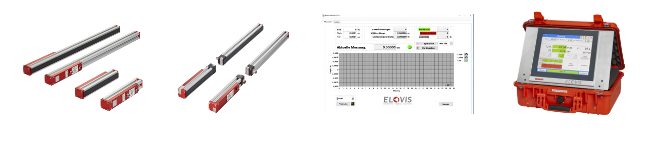

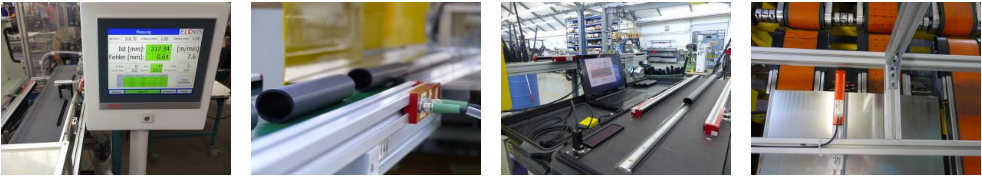

ELOVIS offers non-contact gauges for remeasuring part lengths on the basis of the worldwide unique length-section light scanner technology. With a typical measuring accuracy of 1/10 mm per meter measuring length, the SLM discrete part length measurement systems can currently be offered for measuring lengths of up to app. 15m. For even longer lengths, ELOVIS offers the μSPEED laser-encoder series. The non-contact re-measurement of the part lengths takes place in the production process, during their transport in longitudinal direction. The measurement is used for good / wast sorting and documentation of the delivery condition of the parts as well as the production and length optimization. SLM gauges are maintenance-free, permanently calibrated and measure largely independent of material. The systems are used to measure the length of parts or pieces of profiles, pipes, plates, beams, bolts, struts, beams, rails, hubs made of a wide variety of materials. The robust sensor technology is easier to integrate into the process than it seems – and the production line does not have to grow, when extended by the SLM gauge. Measuring and rejecting of parts is possible in one and the same place.”Non-contact Discrete Part Length Measurement – by the length section gauges of the SLM series from ELOVIS – is user-friendly, safe, robust, reliable and highly accurate”.

Measure piece lengths up to 5m

in transmitted light

Do you still measure piece lengths by hand in samples? Incoming and outgoing material edges ensure increased wear and...

Measure part length up to approximately 15 m

in transmitted light

The final measurement of very large parts is complex, staff-intensive, but still prone to error. If the maximum measu...

Length Measurement of long parts

in reflection

The measurement situation prevents the use of a transmitted light system for part length measurement? The space avail...

More

Measure part lengths

with free-form edges, Application Videos Part Length Measurement

Measure part lengths

with free-form edges

You want to measure the length of parts with free-form edges? ... With the μVIS based 2D and 3D sensors a variety of ...

Non-contact discrete part length measurement: The non-contact ELOVIS part length measuring instruments are listed here. The advantages resulting from the use of these measuring devices are named afterwards.

ELOVIS length measuring device, non-contact for part lengths:

- Discrete part length measuring system

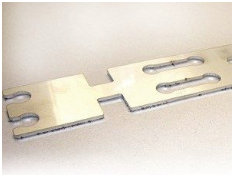

- Light curtain, length-section light scanner, transmitted-light measuring grid, optical caliper, automation light grid

µMETER-SLM

- Vision sensor, camera system, matrix and line scan camera

µMETER-VIS

Measurement advantages with non-contact ELOVIS measuring instruments:

- Wear-free, maintenance-free, permanently accurate ⇒ no maintenance costs, minimum operating costs

- Self-monitoring ⇒ Warning in case of defect

- Suitable at high speeds ⇒ prepared for the future

- Prevention of contamination ⇒ no carryover of impurities

- Large distance tolerance range ⇒ Thickness-independent measurement

- Material-independent measurement ⇒ Measuring principle largely eliminates the influence of material variation

- Longlife LED components ⇒ long sensor life

- Measurement of all parts instead of random tests ⇒ 100% documentation and traceability of measurement results

- Traceable, calibratable, conformity assessable ⇒ Legal certainty

Non-contact discrete part length measurement: The list shows the applications for non-contact ELOVIS part length measuring instruments.

Measure discrete part lengths up to 5 m by length-section light scanner:

Piece lengths, fixed lengths in high speed at 4 m / s measure. Thereby length sorting for guaranteed 100% good parts delivery. Option: Cutting control and cutting length optimization for error prevention

Measure discrete part lengths up to approx. 15 m by length-section light scanner:

Re-measuring of very long piece goods with two-part longitudinal light grid

Measure long lengths with laser-encoders:

Measure any length of discrete parts during production and during transportation contactless and accurate

Measure discrete parts with free-form edges to length:

Free-form edges are detected with vision sensors and derived therefrom length measures

Touching, tactile piece or part length measurement: Here are the typical traditional and mostly touching length measuring instruments for part lengths listed. The measuring problems resulting from the use of these measuring devices are also named.

Part Length Measurement Device, traditional, tactile:

- Sampling inspection by hand with contact measurement devices

- Meter stick, caliper, tape measure

- Measuring stop with steel ruler

- Measuring wheel, impeller

- Measurement via belt pullout, drive, drive roller, measuring roller

Measurement problems with traditional part length measuring equipment:

- Material movement too fast (henceforth only sampling inspection)

- Measurement and measurement accuracy depending on the operator

- Transposed digits by visual reading and manually entering the results in lists

- Lack of accuracy due to slippage on tactile encoders

- Lack of measurement accuracy due to surface dependency with tactile systems

- Measurement deviations due to thickness dependence of tactile systems

Consequences of measurement problems:

- High staff costs

- Operator-dependent scattering of measurement values

- Complaints due to length errors

- Length additions to avoid complaints

- Great effort through follow-up with error message in sample

- Great effort through post-processing of parts

- Lack of traceability

Non-contact discrete part length measurement: Non-contact ELOVIS part length measuring instruments are used in the following industrial sectors for the measurement of piece goods lengths.

Production of semi-finished goods (part length):

- Paper and board industry (winding cores, reel cores, roll widths in longitudinal pass)

- Plastic industry and extrusion (profile, hose, pipe, sealing industry, …)

- Carpet and floor covering industry (roll width, tiles, …)

- Metal industry (sheets, blanks, tubes, profiles, bolts, rods, ingots, …)

- Furniture industry (furniture panels, doors, window frames, …)

Construction industry (part length):

- Wood industry (logs, boards, KVH, beams …)

- Drywall (plasterboard, chipboard, MDF boards, HDF boards, OSB boards

- Insulation industry (insulation panels, fiberglass panels, Rockwool panels, …)

Packaging / transport industry (packing dimension):

- packaging, packaging material (boxes, packages, pallets, …)

Non-contact discrete part length measurement: List of some application videos of ELOVIS measuring instruments for piece goods Length measurement in industrial applications:

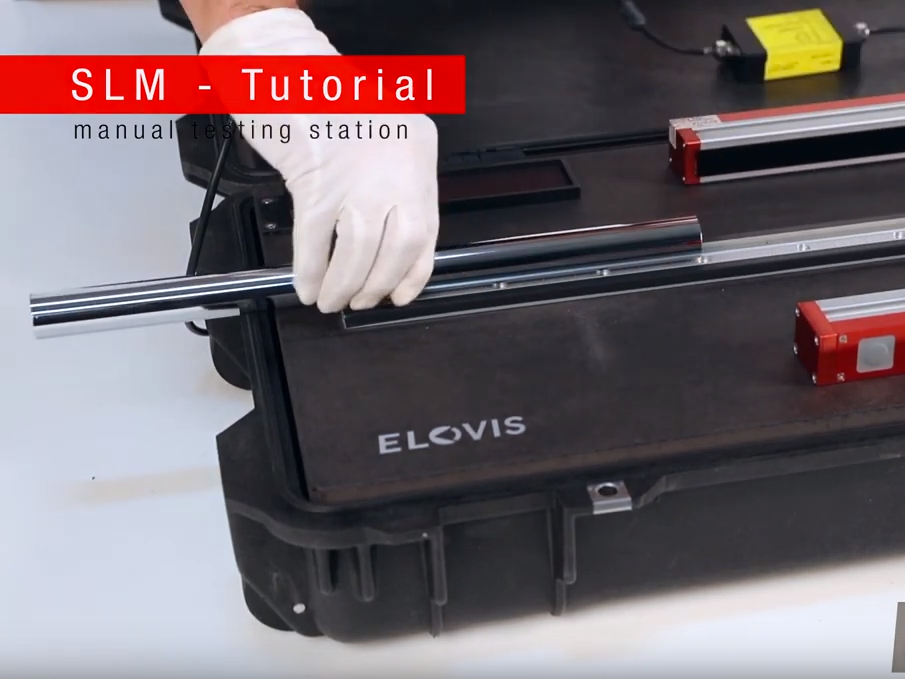

| Product-Tutorial – SLM

Length-Section Light Scanner Part Length Measurement Systems – SLM Setup |

|

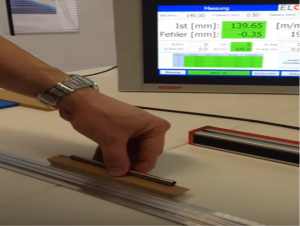

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems – Manual Tube Measurement |

|

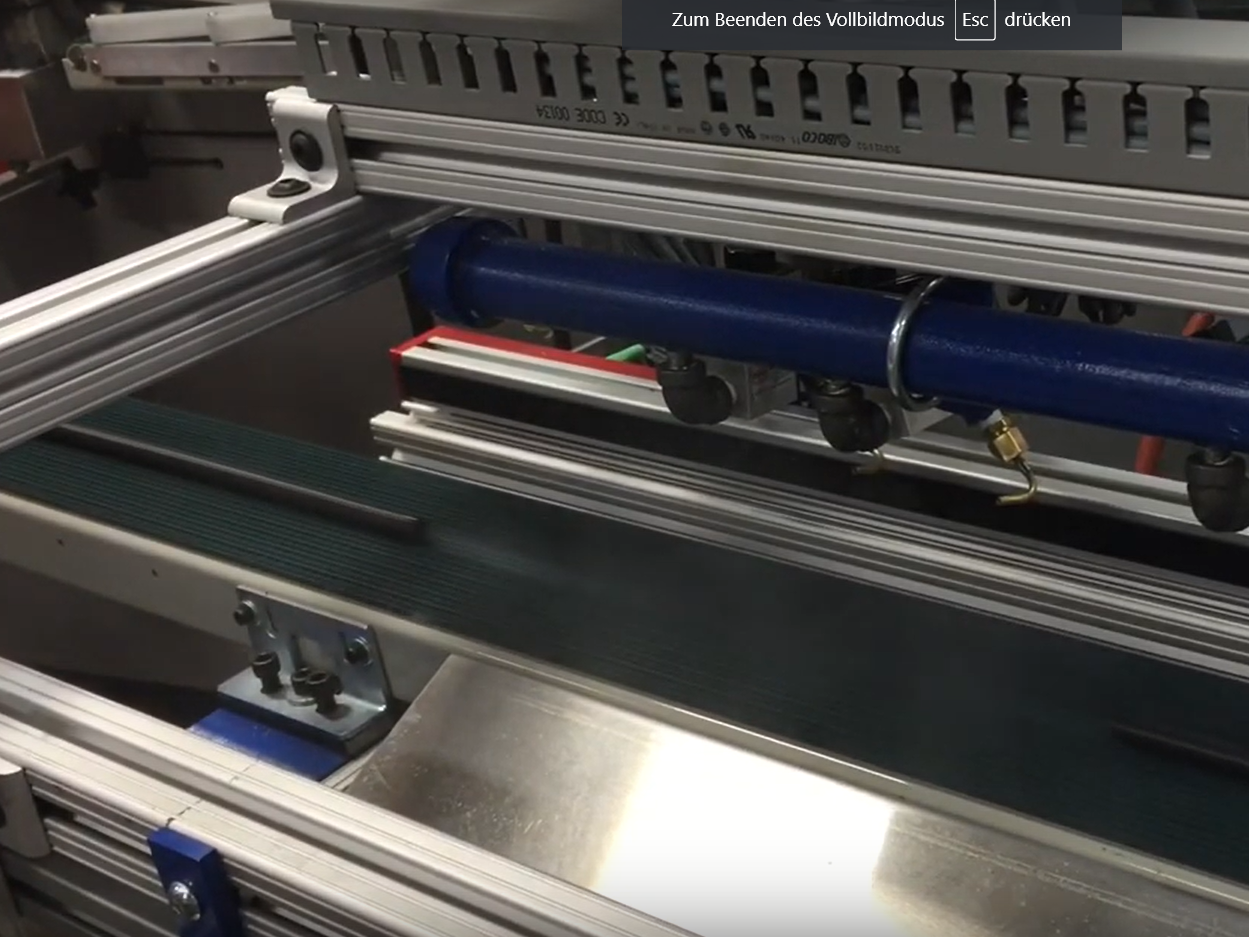

| Applikationsvideo – SLM

Length-Section Light Scanner Part Length Measurement Systems – Measurement and sorting for long plastic tube and 100% documentation of results |

|

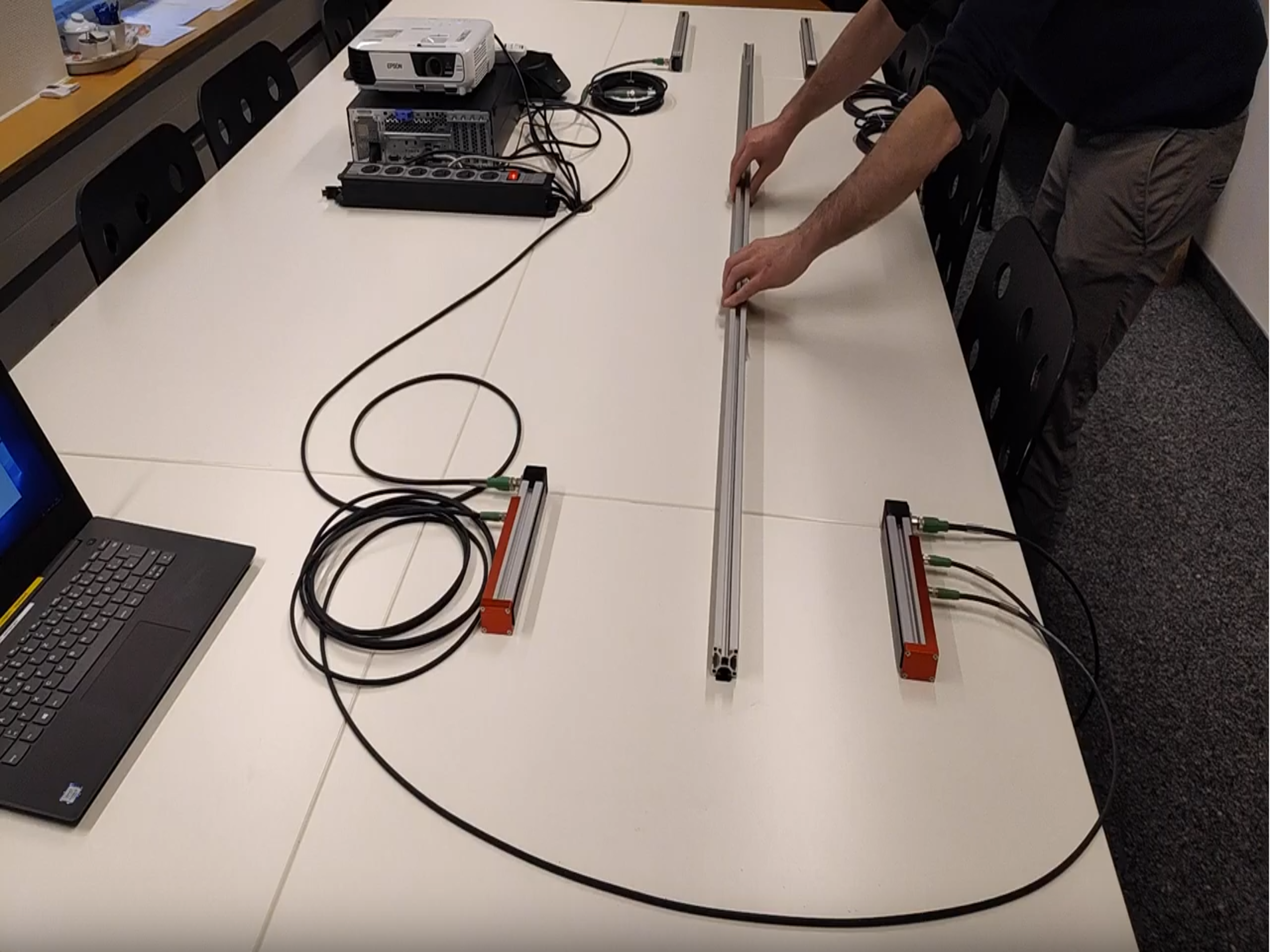

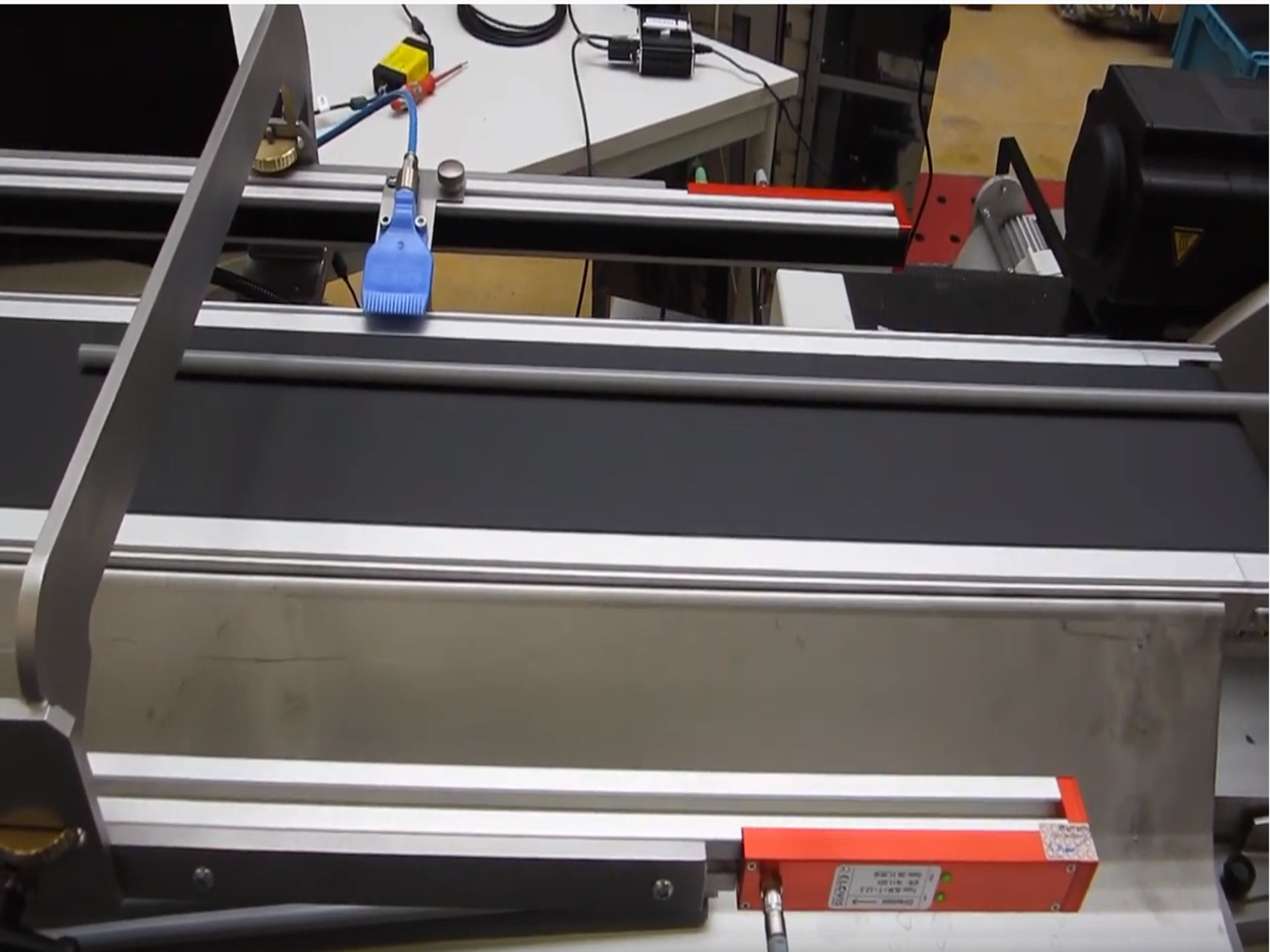

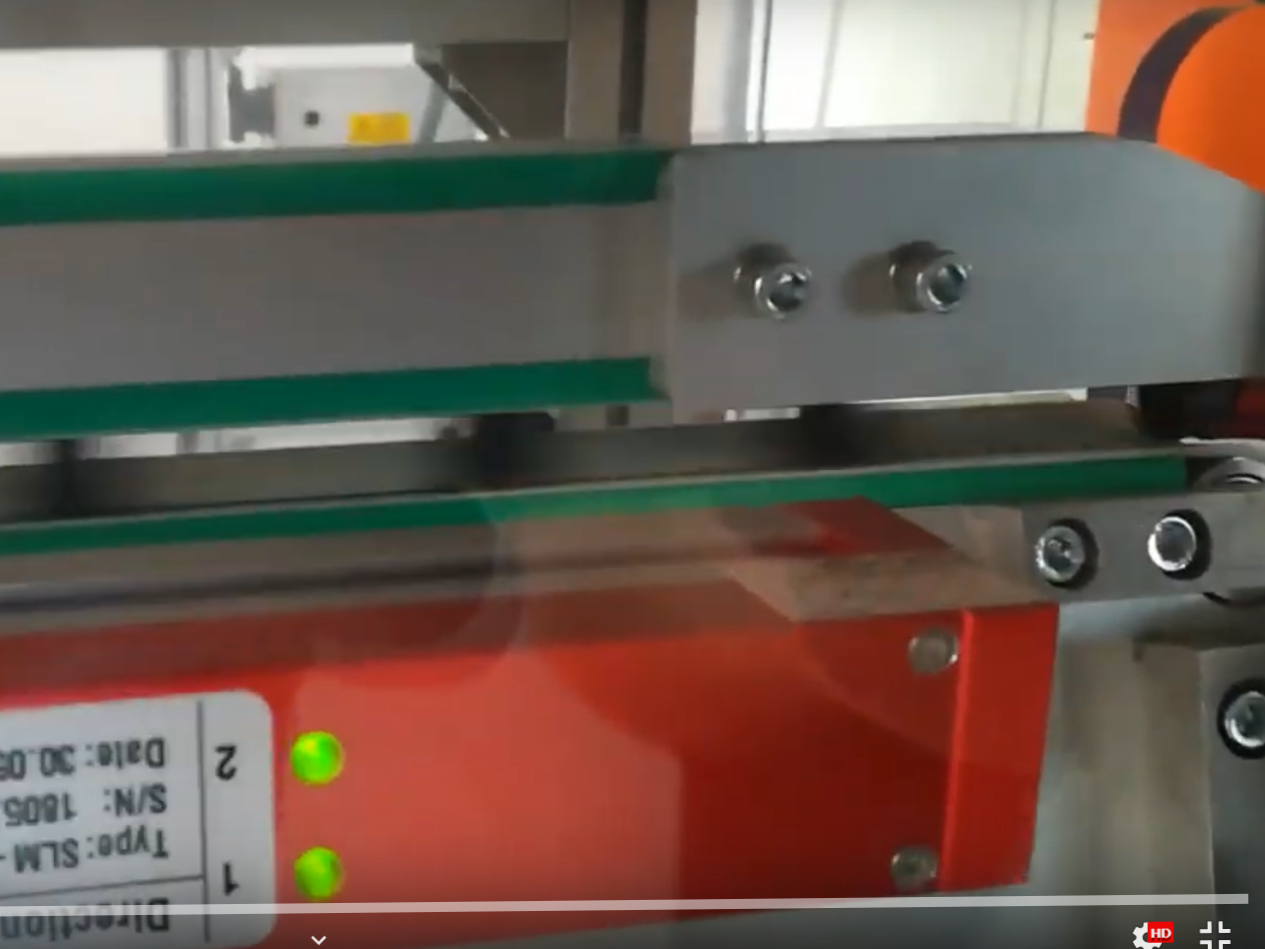

| Application Video – SLM/2

Length-Section Light Scanner Part Length Measurement Systems – Length Measurement System for long discrete parts SLM/2 – Aluminium profiles |

|

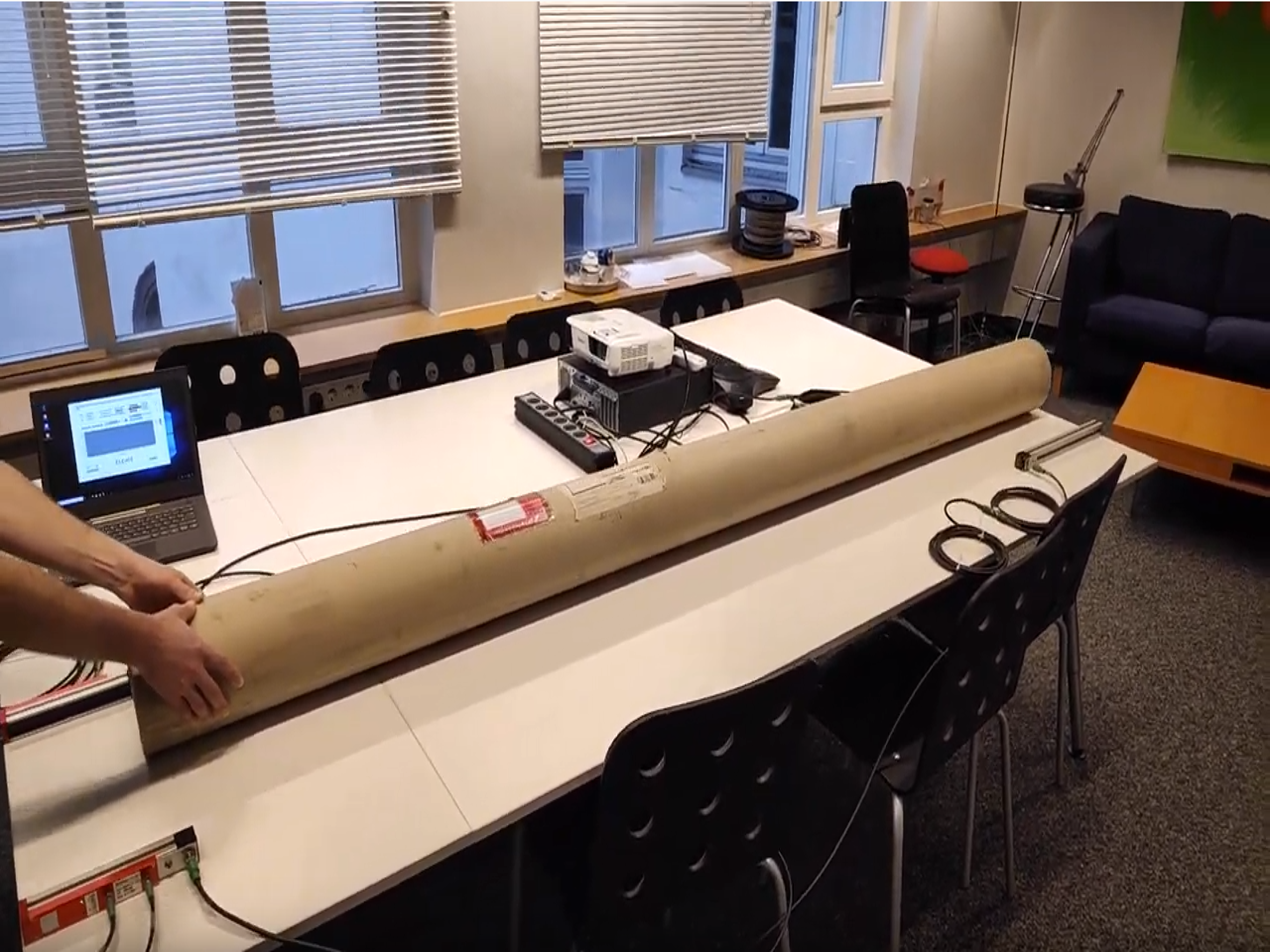

| Application Video – SLM/2

Length-Section Light Scanner Part Length Measurement Systems – Length Measurement System for long discrete parts SLM/2 – tubes |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems -Measurement of profile length with SLM plus PLC for material sorting |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Measurement of film sheet length after cutting, before sorting and packaging |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Length Measurement of cut tubes with material good/waste sorting |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems and sorting Part Length Measurement on short plastic profiles at high speeds |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems and sorter device Part Length Measurement of 354 mm long plastic profiles after extrusion and cut |

|

| Applikationsvideo – SLM

Length-Section Light Scanner Part Length Measurement Systems and sorter device Part Length Measurement of short plastic tubes after extrusion and cut |

|

| Applikationsvideo – SLM

Length-Section Light Scanner Part Length Measurement in a tube processing machine Part Length Measurement and sorting of stainless steel tubes |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Small tubes in manual part guidance |

|

| Application Video – SLM

Length-Section Light Scanner Part Length Measurement Systems Width Measurement of Rolls with SLM |

|

ELOVIS Services

ELOVIS offers the following services for non-contact discrete part length measurement:

- Consulting regarding part length measurement

- Measurement & calibration services

- System rental and sales of tactile and non-contact gauges

- Assistance in dealing with length complaints of your customers