measurement during material movement, cross to the feeding direction

Do you measure the widths and heights of profiles in random samples, because optical micrometers can only cope with perfect material guidance, or because permanently contact measurement systems affect your material? … Generally, in the production of profiles, pipes and hoses a random sample inspection of the main dimensions width, height or diameter happens in the setup process. The material produced in the meantime moves into the rejects. In the current production process, the dimensions can only be checked to a limited extent with previous measurement devices. After the production is finished samples can be taken and measures can be checked. If there are deviations from the nominal dimension, the entire batch is declared as waste. … The solution is the non-contact cross-section light scanner, which works properly despite limited material guidance, for example in case of transverse and diagonal movements as well as material sag. The measurement is used for production control or for the error message when the tolerance is exceeded as well as for the documentation of the delivery quality. µMETER_X cross-section light sensors are used to measure the width, height and diameter of profiles, tubes, hoses, bolts, bars, beams and rods made of various materials.

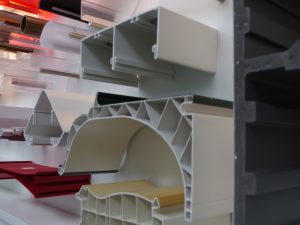

Typical measurement objects using non-contact width measurement and height measurement::

- Profiles, pipes hoses, …

- Bolts, ingots, …

- Beams, planks, slats, …

- Rods, round rods, edged rods, …

- Cable, wire, …

Typical machines using width and height measurement systems:

- extrusion machines

- roll form machine

- milling machines

- calendering machines

- laminators

Application Examples

Dimension of extrusion profiles

The early knowledge of the profile dimensions, such as height, width, gap dimensions, ... helps to timely counteract ...

Matching Products and Services

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offers the following services in this area:

- Advice on non-contact width-height diameter measurement

- measurement services

- Measurement System Rent

- Help in finding system malfunctions

- OEM sensor developments in width-height diameter measurement