Non-contact cross-section measurement of profiles, pipes, hoses

The early knowledge of the profile dimensions, such as height, width, gap dimensions, … helps to timely counteract a reject production in the extrusion. If a measurement system is easy to operate, to set into operation as well as being reliable and not being vulnerable to material position changes, then extrusion has a powerful tool in hand. Height, width, gap dimensions, diameter of extrusion profiles are measured without contact inline by cross-section light scanner. The cross-section light sensors measure accurately, are maintenance-free and permanently calibrated.

Typical application data:

- Measurement of profiles after extrusion, before or after calibration, before cutting

- Production speeds: typically up to 60 m / min

- Problem with contact measurement devices: only sample inspection possible, accuracy: +/- 0.1 mm

- Measurement accuracy with non-contact cross-section measurement BDM: typical: 0.01 mm

- Amortization: 2 months, integration of the measuring system into the existing system technology

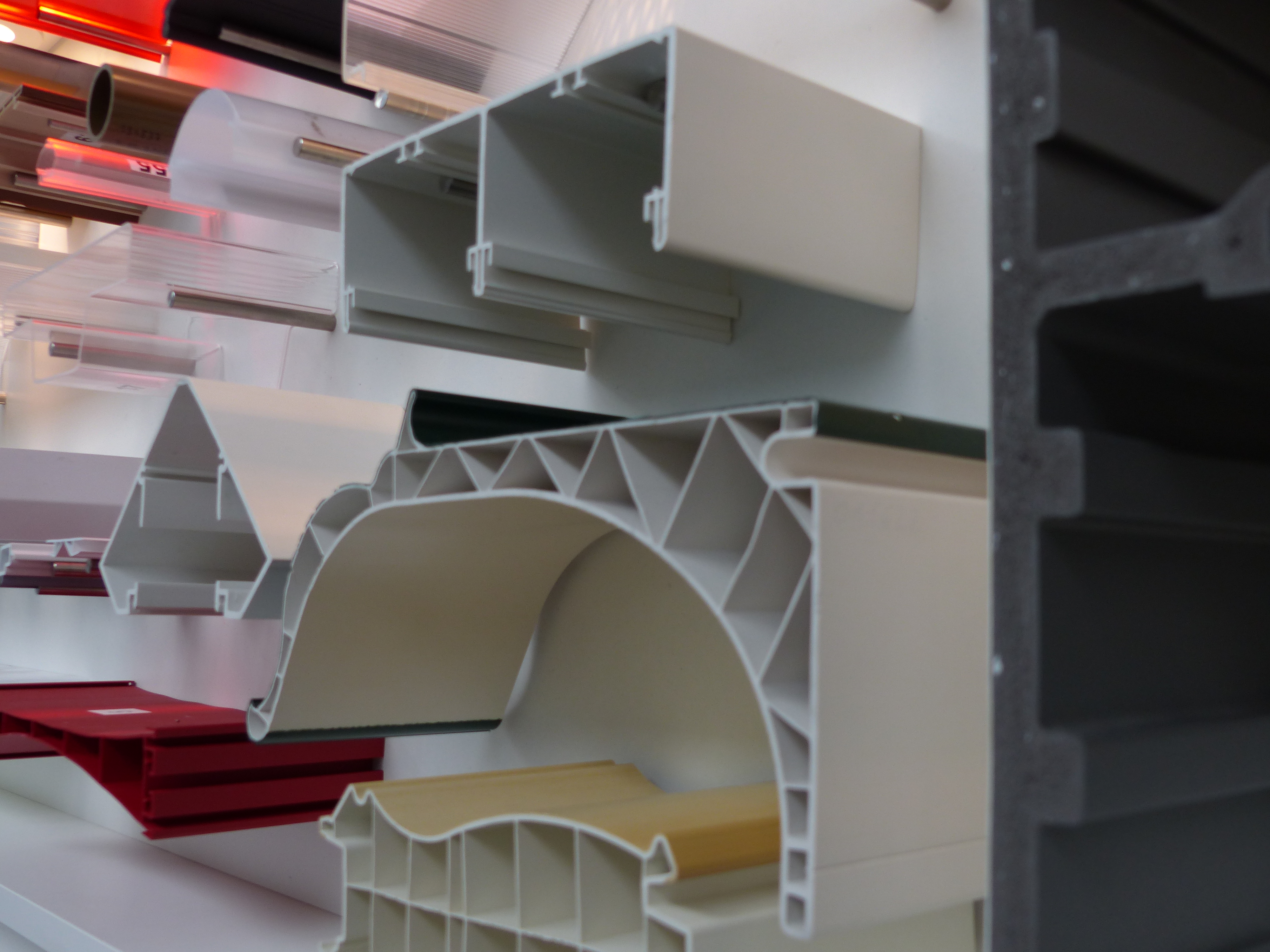

Material examples:

- Extruded profiles of hard and soft plastic as well as co-extrusion and tri-extrusion

- Materials: PVC, ABS, PP, PC, PMMA, ASA and TPU

- Products: Cable ducts, power guides, sealing profiles, pipes, hoses, corrugated pipes, …

Machines equipped with non-contact cross-section measurement:

- Extrusion lines, calibration lines, …

- Drawing lines, …

Matching Products and Services

Cross-Section Light Scanner

Width-Height-Diameter Measurement Systems

- Non-contact width, height and diameter measurement in the production process or in a cycle

- Highly precise cross section measurement, monitoring of dimensional tolerance, regulation and documentation

- LED-based light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer in order to measure lengths of profiles, tubes, plates, beams, rolls

ELOVIS Services

ELOVIS offer the following services for the measurement of widths, heights, diameters:

- Advice on cross-section measurement

- measurement services

- Help with complaints from your customers

- OEM sensor developments in the field of cross-section measurement