Roll Length, Cut-to-Length Control, Calibrated MID and Portable Length Measurement, Print Control, Pattern Repeat Length Measurement, …

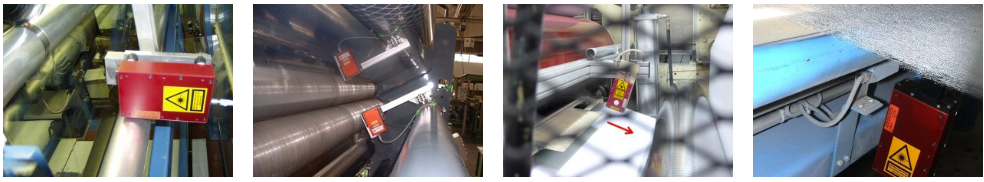

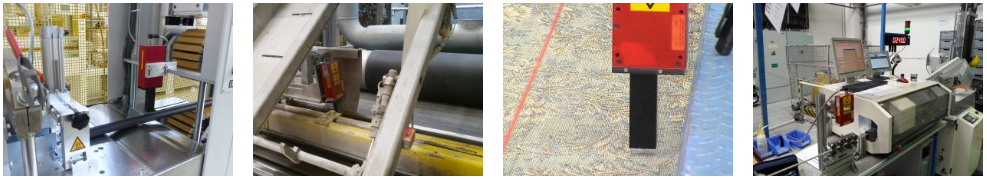

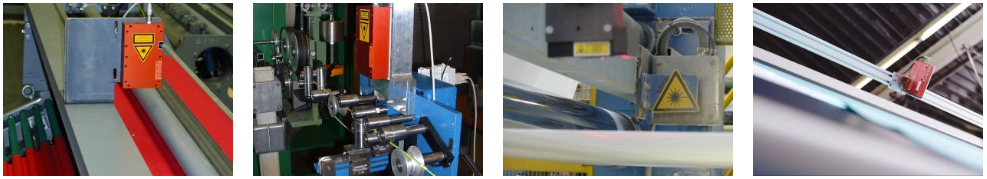

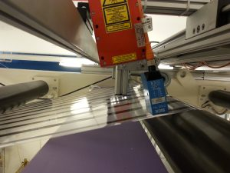

With its non-contact gauges for length measurement, ELOVIS replaces measuring wheels and drive-based or measuring roll-based measurement solutions. ELOVIS gauges are mounted at a safe distance to the transport conveyor and measure the length of the passing material surface. The sensors are used for measuring roll lengths, winding lengths and coil lengths, as well as for cutting or cut-to-length control. The gauges measure webs, ribbons and stranded or spooled goods as well as goods in pieces made of a wide variety of materials. ELOVIS also offers calibratable length measuring systems in accordance with the European Measuring Instruments Directive MID 2014/32/EU. Non-contact length measurement offers significant accuracy and application advantages over conventional measurement methods in mobile, tripod-based measurement, encoder calibration and in the measurement of elongation and shrinkage of goods. Several thousand successful installations speak for themselves: “Non-Contact Length Measurement – by the laser-encoder gauges of the μSPEED series from ELOVIS – is user-friendly, handy, robust, reliable and permanently accurate”.

Roll Length/Coil Length

Is your billing based on correct length values? Are all materials measured with same accuracy? Or do you risk len...

Cut-to-length Control

Do you avoid length additions or do you deliver excess length just to be safe? Do you have the strict requirement to ...

MID certified Length Measurement

If goods are sold in Europe by length or area, they generally must be measured with "MID-certified" calibrated length...

More

Portable/Mobile Length Measurement, Encoder Calibration, Discrete Part Length Measurement, Measurement of Mark Distan...

Portable/Mobile Length Measurement

Where do you lose lengths during the production process? Where does waste or rejects occur? Does material shrinkage o...

Encoder Calibration

Do all system counters work with the same accuracy across the production spectrum? Which method do you use to check t...

Discrete Part Length Measurement

Are you interrupting your production or reducing the throughput speed to check lengths manually? Sample test costs pr...

Measurement of Mark Distances

The purpose of pattern repeat length measurement is to shorten the running-in process and to achieve permanently corr...

Differential Length Measurement

Length differences are often caused by the process. Reasons are drying, moisture input, thickness change, tensile str...

Measurement of Stretch and Shrinkage

The determination of material stretch and material shrinkage is an important process parameter for you? Whenever the ...

Length-proportional imprint

Do you print products in the process with a length measurement? However, the length varies depending on the products ...

Non-contact length measurement: The list shows the applications for non-contact ELOVIS length gauges.

Measure roll length / coil length:

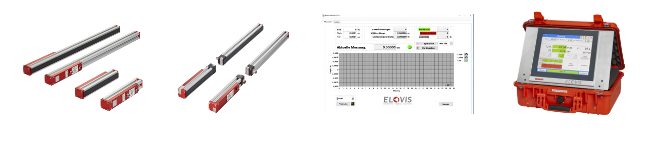

Length measurement on moving webs, tapes, rolls, wraps, bobbins

Cut-to-length control:

Control of cutting, cutting and finishing processes

Calibratable length measurement:

Length measuring machines with “Type Approval”, “Type Examination Certificate”, conformity assessment acc. MID 2014/32 / EU

Portable / mobile length measurement:

Portable length measurement systems for tripod mounting for calibration of system counters

Encoder calibration:

Length measuring systems for calibrating wheel encoders and machine encoders

Length measurement on moving discrete parts:

Non-contact and accurate measuring of piece lengths in high-speed continuous operation

Differential length measurement:

Parallel length measurement at separate measuring positions for process control

Measurement of mark distances:

Length measurement from mark to mark (repeat length measurement)

Measurement of elongation and shrinkage:

Differential length measurement for determining the elongation and shrinkage of materials in the machining process

Control of length-proportional scale imprint:

Print control via the output of length-proportional pulses to a printing / marking unit

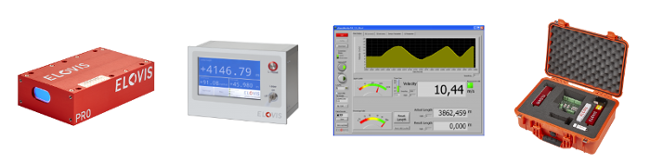

Non-contact length measurement: The non-contact ELOVIS length measuring devices are listed here. The advantages resulting from the use of ELOVIS gauges over other gauges are named afterwards.

ELOVIS length measuring instruments, non-contact length measurement:

- Laser Encoder, Laser Doppler Velocimeter, Surface Velocity Measurement System

µSPEED

- Light Scanner, light curtain, transmitted light measuring grid, optical caliper, automation light grid

µMETER-SLM

- Vision sensor, camera system, matrix and line scan camera

µMETER-VIS

Measurement advantages with non-contact ELOVIS measuring instruments over other gauges:

- Wear-free, maintenance-free, permanently calibrated ⇒ no maintenance costs

- Self-monitoring with early warning system ⇒ failure protection

- Suitable at high speeds ⇒ prepared for the future

- Prevention of traces of wear ⇒ no material damaged, no carryover of impurities

- Large measurement distance tolerance range ⇒ Thickness-independent measurement

- Measuring principle eliminates the influence of material variation ⇒ Material-independent measurement

- Longlife laser and LED components ⇒ Long measuring life

- Digital measurement of all lengths ⇒ 100% documentation and traceability of the measurement results

- Traceable, calibratable, conformity assessable ⇒ Legal certainty

Non-contact length measurement: Non-contact ELOVIS measuring devices are used in the following industrial sectors for length measurement.

Production of semi-finished goods:

- Paper and board industry (paper raw material, rolls, sheets, …)

- Printing and packaging industry (rolls, labels, sheets, …)

- Plastic industry (extrusion, profile, hose, pipe, foil, film industry, …)

- Textile industry (technical textiles, fabrics, nonwovens, …)

- Carpet and flooring industry (rolls, tiles, …)

- Metal industry (web, bands, sheets, tubes, profiles, wire, cables, …)

- Cable and wire industry (rolls, spools, cut, strip and terminate, …)

Construction industry:

- Wood industry (veneer, firewood, slabs, …)

- Drywall (boards, slabs, strips, …)

- Insulation industry (webs, rolls, plates, …)

Automotive industry:

- Automotive industry (measurement of driving distance for cars, trucks, rail vehicles, trains, sports vehicles, …)

Touching and tactile length measurement: The typical traditional and mostly surface touching length measuring instruments are listed here. Measurement problems resulting from the use of these measurement devices are also listed in the following.

Length measurement devices, traditional, tactile:

- Contact measuring wheel, impeller, measuring crawler

- Measurement via drive, drive cylinder, measuring roller

- Sample random testing by tape measure

Measurement problems with traditional contact measurement devices:

- Lack of accuracy due to slippage of tactile driven encoders (Wear, contamination, adhesion problems, accelerations, …)

- Lack of measurement accuracy due to surface dependency with tactile measurement systems (Moisture, strength, softness, roughness, elasticity, …)

- Measurement deviations due to thickness dependency of contact measurement systems

- Problems at high temperature with contact driven measurement systems (hot material)

- Too fast material movement (henceforth only random checks feasible)

Consequences of measurement problems:

- High maintenance effort

- Complaints due to length errors

- Delivering add-on lengths to avoid complaints

- Compensation due to lack of transparency and traceability

- Legal uncertainty in regulated markets (European measurement directive, …)

Non-contact length measurement: List of application videos of ELOVIS measuring instruments in industrial use:

| Product Tutorial – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Tutorial |

|

| Product Video – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Explanation and Application Overview |

|

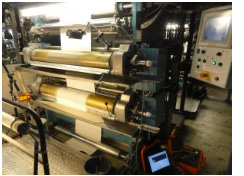

| Length Measurement in Fabric Production – µSPEED

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Measurement at the production output with a portable µSPEED system |

|

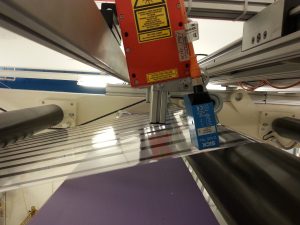

| Repeat Length Measurement – µSPEED-RL

Laser Encoder Length Measurement Systems and Speed Measurement Systems Laser-precise measurement of repeat mark distances in a film printing machine |

|

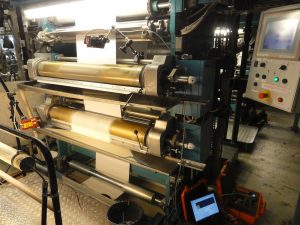

| Differential Speed Measurement in Foil Coating Production – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Measurement on a web and parallel on the coating roller with μSPEED parallel systems |

|

| Paper-Roll Cutter Counter Calibration – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Calibrating the length counter of a winder with a portable μSPEED sensor |

|

| Tenter Frame Shrinkage Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Differential measurement in the goods infeed as well as in the goods outfeed for the determination of the goods advance |

|

| Wire Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in bare-wire production with μSPEED laser system |

|

| Steel Rope Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Testing the measurement accuracy of a system counter for ropes with portable μSPEED laser sensors |

|

| Textile Fabric Inspection Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement machine for textiles is calibrated without contact with μSPEED |

|

| Nonwoven Length Measurement – µSPEED

Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in a nonwoven fabric production machine without contact with μSPEED laser Doppler system |

|

ELOVIS Services

ELOVIS offers the following services for non-contact length measurement:

- Consulting regarding length and speed measurement

- Measurement & calibration services

- System rental and sales of tactile and non-contact gauges

- Assistance in dealing with length complaints of your customers