Measurement Solution based on combined single Gauges

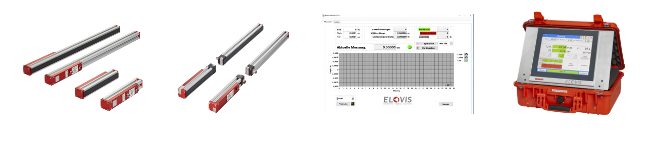

ELOVIS sensors are designed to be combined to offer complete measurement solutions from a single source. Typical combined dimensional control applications include e.g. systems for length measurement in combination with systems for width and thickness measurement. Both length measuring gauge types, either the laser-encoder family μSPEED or the discrete part length measuring systems of the SLM family can be used here. In addition to the width measurement, height and thickness measurement, other parameters, such as angularity, parallelism or the diagonal measure can be determined. ELOVIS gauges of the μMETER-X family are used here. Non-contact dimensional control usually takes place during the ongoing production process during material transportation. The measurement serves for the inline monitoring of the dimensions for compliance with the product tolerances and documentation of the delivery condition and, if applicable, the feedback to the process and machine control. All optical ELOVIS sensors are maintenance-free, permanently calibrated and measure largely independent of material. Combined measuring systems are available for the measurement of profiles, tubes, plates, beams as well as webs and tapes made of different materials.

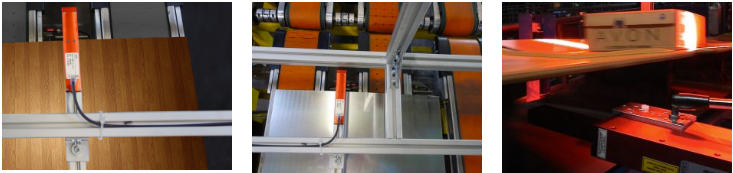

Length, Widht, Thickness, Angles, Parallelity for Plates, Boards

If several dimensions of semi-finished products have to be checked to secure subsequent processes, combined measureme...

Length, diameter, gap size of profiles, hoses, pipes

In the production of profiles, hoses and pipes, it is important to comply with different tolerances and to optimize o...

Web Length and Width Measurement

Widths of web, tape and other rolled goods are usually measured by hand in random samples, because touching measuring...

Combined applications for dimensional control: The non-contact ELOVIS measuring instruments for length, width, height and thickness measurement as well as squareness and parallelism are listed here. The advantages resulting from the use of these measuring devices are named afterwards.

ELOVIS measurement solutions for non-contact control of length, width, height, angularity, … by combining individual sensors:

- Length measurement

µMETER-SLM

- Width, height and diameter measuring system

- Light grid, cross-section light scanner, light curtain, transmitted light measuring grid, optical caliper, automation light grid

- Vision sensor, camera system, matrix and line scan camera

µMETER-VIS

Measurement advantages with non-contact ELOVIS measuring equipment:

- Wear-free, maintenance-free, permanently accurate ⇒ no maintenance costs, minimum operating costs

- Self-monitoring ⇒ Warning in case of defect

- Suitable for high product speeds ⇒ prepared for the future

- Material-independent measurement ⇒ Measuring principle largely eliminates the influence of material variation

- Long life LED components ⇒ Long measuring system life

- Measurement of all parts ⇒ 100% documentation and traceability of measurement results

- Traceable, calibratable, conformity assessable ⇒ legal certainty

Combined applications for dimensional control: The list shows the applications for non-contact ELOVIS measuring devices for the measurement of a wide variety of measured variables.

Combined measurement of length, width, height, diameter, angularity, parallelism, … with contactless ELOVIS sensors:

Dimensional control in the pass at high goods speed. This error message when exceeding the tolerance or parts sorting / guaranteed 100% goods delivery. Also intervention in machine regulations for error prevention

Dimensional control of sheets and boards

– length, width, thickness, squareness

Article identification due to dimensions

– Furniture panels

– Packages

Dimensional control in logistics

– Package and pallet dimensions

– Height width length

Dimensional control of profiles, hoses, pipes

– Diameter, length of piece, gap dimensions, profile dimensions

– Roll length

Dimensional control in roofing membrane production

– Roll length measurement

– Width measurement

– Layer order measurement

Dimensional control in paper roll production

– Roll length measurement

– Roll width measurement

Rapport length measurement on printed foils

– web speed

– Repeat marker distances right, left, delay

Measure free shapes and profiles using 2D and 3D sensors:

– Freeform dimensions, length, width, thickness, squareness

Combined Tactile Measurements Applications: Typical traditional and mostly touching measuring instruments for length, width, height and diameter measurement as well as squareness and parallelism are listed here. The measuring problems resulting from the use of these measuring devices are also named.

Dimensional control for length, width, height, angularity – traditionally tactile:

- Meter stick, caliper, tape measure

- Measuring stop with steel ruler

- Manual sampling

Measurement problems with traditional measuring equipment:

- Material movement too fast (henceforth only random checks)

- Measurement and measurement accuracy depending on the operator

- Errors by visual reading and manually entering the results in lists

Consequences of measurement problems:

- High staff costs

- Operator-dependent measurement spread

- Complaints due to width / height error

- Dimensional additions to avoid complaints

- Big effort through manual sample testing after error message

- Big effort in post-processing of parts

- Lack of traceability

Combined dimensional control applications: Combined non-contact ELOVIS measuring devices are used in the following industrial sectors.

Semi-finished goods production (widths, diameters):

- Plastic industry and extrusion (profile, hose, pipe, sealing industry, …)

- Carpet and flooring industry (roll width, web width, …)

- Metal industry (sheets, blanks, tubes, profiles, bolts, rods, bars, …)

- Furniture industry (furniture panels, doors, window frames, …)

- Paper and board industry (hubs, cores, width in transverse movement, roll diameter during longitudinal movement)

Construction industry (panel widths, thicknesses):

- Wood industry (piece wood, boards, KVH, beams …)

- Drywall construction (plasterboard, chipboard, MDF boards, HDF boards, OSB boards

- Insulation industry (insulation panels, fiberglass panels, Rockwool panels, …)

Packaging / transport industry (package dimensions):

- Packaging material, packaging material (boxes, packages, pallets, …)

ELOVIS Services

ELOVIS offers the following services for combined non-contact measurement gauges:

- Consulting regarding combined measurement of length, part lenght, width, height, thickness, diameter

- Measurement & calibration services

- System rental and sales of gauges

- Assistance in dealing with measurement complaints of your customers