ELOVIS Industrial Measurement Technology

Non-contact Measurement of Length, Speed and Part Length …

ELOVIS is all about accurate and non-contact measurement of geometrical and dynamic measurands. ELOVIS gauges are integrated into the manufacturing process and are designed for harsh industrial environments. Gauges for non-contact measurement of length, speed and part length as well as gauges for contact free width measurement are the main product focus. Additionally ELOVIS is a sought-after partner for measurement services and for consulting in the field of measurement technologies since 25 years. System rental, system sales and the development of customized sensor technology complete the ELOVIS offer. Do you have measuring tasks, questions about our products and services, do you need a quotation … do you want to apply for a job … then click on the red button “Contact” on the right-hand side of the page!

We are expanding our teams in development, production and sales and are looking for inquisitive, motivated employees who share our drive and enthusiasm for convincing technical solutions. We are looking forward to employees who identify themselves with their ideas and their work and who will continue to drive the development of the company together with us. With us, you can expect a highly motivated team, creative freedom to shape your working style, performance-based pay, flexible arrangements and excellent opportunities for further development.

Non-contact length measurement of web material and strips

Non-contact surface speed measurement

Non-contact measurement of part length and goods in parts

Non-contact width and diameter measurement for belts and plates

Wireless measurement data transmission, vibration, oscillation measurement

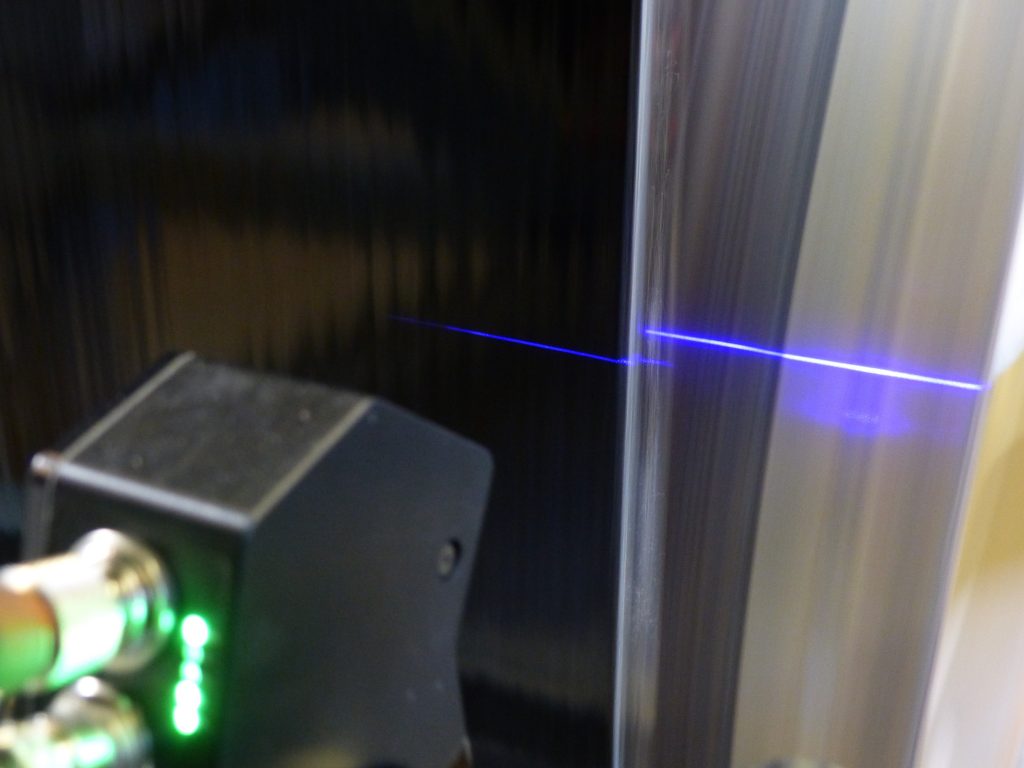

Laser Surface Velocimeter based on laser-doppler principle for length and speed measurement

Certified length measurement systems acc. European Measurement Instruments Directive MID2014/32/EU

Optical Micrometer for accurate discrete part length measurement integrated into the production process

Optical Micrometer for width and diameter measurement transverse to the transportation direction

Systems for wireless, synchronous measurement data transmission as well as vibration measurement

The non-contact measurement of length, speed and part length is only a part of the measurands that can be measured by ELOVIS sensors.

ELOVIS offers industrial measurement solutions for the measurement of:

Length | Speed | Part Length | Movement | Standstill | Direction of Movement | Width | Height | Diameter | Perpendicularity | Parallelism | Measurement of Diagonals | Area Measurement| Cross-Sectional Area| Volume | Volume Flow | Slippage | Elongation | Shrinkage | Repeat Length | Mark Distances | Web Distortion | Transverse

Distortion | Longitudinal Distortion | Vibration | Oscillation

The exact, non-contact measurement of length, speed and part length as well as measurement of width or cross section area of materials in the production process or during the transport of goods are typical ELOVIS measurement tasks. The measurement is carried out by optical gauges, using different kinds of light and thus is contactless and maintenance-free. ELOVIS developed the first laser encoder systems for measuring length and speed 25 years ago. Since then, μSPEED length gauges and speed gauges for contact-free measurement have been used worldwide in industrial environments. Laser length measurement and laser speed measurement by μSPEED laser encoder systems equipping length measurement solutions and length measurement machines represent the product focus of ELOVIS GmbH.

Other ELOVIS gauges are also measuring contact-free by the use of light. To mention is the contactless, accurate length measurement of discrete parts. The μMETER-SLM gauges were developed especially for this purpose. Optical micrometers of the type SLM are based on the through-light principle, work contact-free and therefore are maintenance-free. Parts and fix lengths are measured in-line, meaning during the production process and whilst still in production. The length measurement system SLM works with high precision and independent of the measuring material without touching the measurement material. The measured parts should be transported straight and separated during SLM measurement.

An additional focus at ELOVIS is calibrated length measurement systems which can be installed in calibrated length measurement machines. Length measurement machines according to MID2014/32/EU are conformity assessed in accordance with the European Measuring Instruments Directive. MID length gauges also comply with the German calibration law. Many calibration offices now have made good experiences with the non-contact measurement technology based on the ELOVIS MID-COUNTER in conjunction with tactile measuring wheel encoders or in conjunction with the ELOVIS laser encoder μSPEED. The German National Metrology Institute PTB (Physikalisch Technische Bundesanstalt, Braunschweig) is the notified body for length measurement and area measurement according to module B and is often used by ELOVIS as the conformity assessment body. Calibrated length and area measurement devices are available from ELOVIS for the measurement of cables, paper, fleece, felt, nonwoven, carpet as well as for floor coverings. Calibrated length counters or so-called MID length counters using the MID-COUNTER in combination with measuring wheel or the MID-COUNTER in combination with laser gauges type μSPEED are also in use in other European countries. All ELOVIS systems are CE certified.

When measuring widths, cross sections, diameters and heights, ELOVIS gauges also use non-contact, contactless or contact-free measurement technology based on laser, LED or structured light technology e.g based on camera vision sensors. All measurements are therefore free of slippage, wear-free, largely independent of material and user-independent, permanently accurate and also maintenance-free.

ELOVIS – Specialists for non-contact measurement of length, speed, part length, …

The measurement of web and strip lengths as well as of long parts is carried out optically by ELOVIS laser surface velocimeter (LSV system) using the laser-doppler method. The gauging technology is called laser encoder or laser speed gauge by ELOVIS. The related product family is named μSPEED.

μSPEED key applications for non-contact measurement of length, speed and part length are: Contactless length measurement of moving webs and belts | Optical measurement of roll length | Measurement of winding length without contact | contact-free length measurement solutions for spooled goods | Optical Laser Length Measurement on Moving Material Surfaces | Optically measure path length | Optical repeat length measurement.

Applications for non-contact measurement of length, speed, part length:

Non-contact length measurement of paper and paper board: raw paper, coated paper, tissue paper, printing paper and packaging paper, photo paper, carbonless paper, thermal paper, decorative paper, cardboard, corrugated paper, sandpaper, abrasive paper.

Contact-free length measurement in the field of plastic and extrusion: foil, film, profile, adhesive film, tape, self-adhesive film, optical film, rubber seal, flat band seals, seals, pipe, hose.

Contactless length measurement of textiles, fabrics and nonwovens: upholstery, artificial leather, headliners, straps, tapes, technical textiles, insulating materials, geotextiles, filters.

Length measurement of floor coverings without contact: carpet, laminate, PVC, parquet, linoleum, cork floors, artificial turf.

Measure lengths of cable and wire without touch: drawing wire, casting wire, electric cable, high voltage cable, stranded cable, stranded wire, submarine cable, ropes, ropes.

Optical length measurement of metal: rods, tubes, plates, sheets, sinkers, slugs, slabs, sheets, strips, aluminum foil, metal foil, silver foil.

Part length measurement in the machining process: such as wood, construction timber, gypsum board panels, chip-board, flake baord, winding cores, cardboard sleeves, metal sheets, metal plates.

ELOVIS – Specialists for non-contact measurement of length, speed, part length.

The measurement of speed is also carried out with laser encoder gauges based on laser surface velocimeter using the laser-doppler method. Laser speed gauges for speed measurement are part of the μSPEED product family.

μSPEED key applications for non-contact speed measurement include: non-contact speed measurement of rotating cylinders and rollers | Optical measurement of reel speed | Touch-free measurement of drive roller speed | contact-free measurement solution for speed adjustment of drives, rollers and web material | Measuring differential speed without contact | Laser speed measurement on moving material surfaces | Optical motion monitor or speed monitor including standstill detection.

Applications for non-contact measurement of length, speed and part length …

Non-contact speed measurement on cylinders to determine roller speed, reel speed, drive roller speed, peripheral speed on chromed and rubberized cylinders.

Touch-free differential speed measurement for speedometer calibration and speed comparison between machine drive and material movement.

Contact-free speed measurement as a trouble-shooting tool to find reasons for material damage, friction marks, scratches and for eliminating web breaking problems.

Non-contact measurement of shrinkage and elongation via differential speed measurement for textiles in the tenter frame/stenter frame applications, or for foils in printing machines.

Optical measurement of material flow in rolling mills and stretching machines.

Process stablization e.g. material congestion detection, edge strip movement and direction detection, standstill detection via non-contact speed measurement.

ELOVIS – Specialists for non-contact measurement of length, speed, part length, …

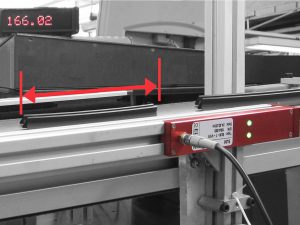

ELOVIS gauges for non-contact part length measurement are length-section light scanners or optical micrometers. The parts are measured during their longitudinal transportation while still in production. ELOVIS gauges are most closely related to measuring light grids or light curtain systems, though a lot more accurate. The product group for part length measurement is called μMETER-SLM.

μMETER-SLM key applications for non-contact measurement of length, speed and part length are: In-process Contact-free measurement of part lengths | Optical measurement of fix lengths | Contactless measurement of sections and saw parts | Touch-free measurement of pipe sections, pipes and hoses | In-situ measurement of parts after cutting.

Applications for non-contact measurement of length, speed and part length …

Non-contact part length measurement after cutting or after the cross-cutter or the guillotine at separated and longitudinally moving parts.

Process control by length-section light scanner, such as e.g. length sorting in good and bad parts, cutting length optimization, cutting control, reject optimization.

Contact-free part length measurement of extruded material, e.g. profiles, tubes, hoses, strips and rails.

Measure contact-free length of plates, sheets, blanks, boards, tiles, sections.

Contactless length measurement of gypsum boards, chipboards, flake boards, furniture boards, OSB boards, fibreboard and MDF boards, plates and construction timber.

ELOVIS – Specialists for non-contact measurement of length, speed, part length, …

ELOVIS gauges for non-contact cross-section measurement and combined dimensional checks are optical micrometers and are called cross-section light scanners by ELOVIS. Measurement happens vertically to the conveying direction of the materials, during production. The product group is called μMETER-X. The systems often occur in combined dimensional checks, e.g. for non-contact measurement of length, speed and part length. μMETER-X key applications for cross-section measurement are: In-process non-contact width measurement of webs | Optical measurement of plate widths moving on conveyor belts and on the roller conveyor | Contact-free measurement of sections and edged strips, plates | Contactless cross-section measurement of profiles pipes and hoses | Insitu measurement after the width cutting.

Applications for non-contact measurement of length, speed and part length, width measurement, …

Non-contact width measurement on webs and strips as well as on web-shaped produced and transported materials.

Contactless measurement of plate geometry (length, width) and the angularity or squareness of plates.

Contact-free measurement of plate diagonals, edge parallelism and edge shape during production and during transport on the roller conveyor or parallel conveyor belt.

Optical profile contour measurement, outer edge measurement and measurement of pipe diameters and hose diameters.

Combined measurement of web widths, strip widths and lengths with optical light scanner gauges.

Add-on gauges for the above-mentioned gauges for optical 2D and 3D measurement or for determination of the meter weight.

ELOVIS – Specialists for non-contact measurement of length, speed, part length, …

Rewinder | Roll Cutter | Roll Cutting Machine | Cutting Machine | Winding Machine | Cross Cutter | Doctor Roller | Fabric Inspection Machine | Inspection Machine | Calander | Finishing Machine | Coating Machine | Saw and Saw Machine | Punching Machine | Laminator | Laminating Machine | Composite Production Line | Converting Machine | Printing Machine | Roller Printing Machine | Extrusion Machine | Extruder | Guillotine | Automatic Cutting Machine and Automatic Packaging Machine | Carpet Printing Machine and Carpet Coating Machine | Carpet Packing Line | Coupons Cutting Machine | Calibrated Cable Measurement Machine | Calibrated Length Gauge and Area Gauge for Paper, Nonwoven, Felt, Carpet, Flooring, Plastic Film, Synthetic / Artificial Leather and Composite Material | Length Measurement Machine with approval according to MID 2014/32/EU / Part Certificate.

ELOVIS industrial gauges for non-contact measurement of length, speed and part length as well as for width measurement optimize numerous converting and production machine types.

ELOVIS – Specialists for non-contact measurement of length, speed, part length, width … cooperate with partners in development and manufacturing of machines and plants.

Here is a selected excerpt from our list of partners:

Gebr. Maag MaschinenfabrikThe company MAAG is leading in its field of fabric inspection machines and length measurement machines for hard-to-measure strip and web products. MAAG often uses μSPEED systems for calibrated machines and has so-called type approvals in order to enable the placing on the market of calibrated machines. Segments: textile, imitation leather, foil, laminated materials and other composite materials. Application Example: Rolling and Inspection Machine Link: http://texmaag.ch |

|

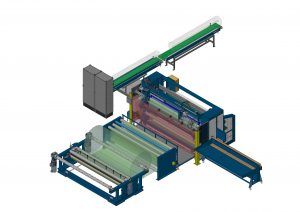

ETF Machinefabriek B.V.In the carpet segment, ETF is the world’s leading company for winding machines, length cutting machines, cutting machines, packaging and sorting machines, electronic measuring systems, fabric inspection machines, coupon cutting machines. ETF uses ELOVIS μSPEED systems for calibrated length measurement machines and has type approvals to enable the placing on the market of calibrated machines. Segments: carpet, non-woven, vinyl Application Example: Carpet Cutting Machine Link: www.etf.nl |

|

Weerth-Handling-Systeme GmbHWHS manufactures machines and plants for the chipless and burr-free cutting of metal pipes. Whenever customers want it to be precise, production plants are equipped with the ELOVIS μMETER-SLM systems in order to safeguard production and, additionally, document the quality. Segments: metal, pipes, stainless steel tubes Application Example: Pipe Separation System Link: http://weerth.com/ |

|

Eugen Riexinger GmbH & Co. KGEugen Riexinger GmbH & Co. KG is a partner for the development and production of sawing machines. Eugen Riexinger’s product range includes semi-automatic and fully automatic saws and sawing systems. Here, the systems will be expanded by μMETER-SLM systems as well when it comes to 100% control. Segments: metal, pipes, stainless steel tubes Link: www.riex.de/en |

|

CAMPEN Machinery A/SPartner for development and production of slitter rewinding machines: CAMPEN off-line slitting machines, wrapping machines and wrapping machines from Denmark are specifically designed machines for cutting and wrapping various types of nonwoven, delicate materials and technical textiles, mainly web-shaped materials. CAMPEN uses ELOVIS μSPEED systems for length measurement in machines with difficult-to-measure materials, but also when it comes to verifiable MID certified solutions. Segments: Application Example: Off-line Slitter Rewinder Link: www.campenmachinery.com |

|

EXTRUDEX Maschinenbau GmbHPartner for the development and manufacture of extruders and downstream equipment: EXTRUDEX manufactures Helibar single-screw extruders, grooved and smooth-tube extruders. EXTRUDEX extruders are mainly used in the automotive and medical technology sectors as well as in the cable industry. EXTRUDEX uses ELOVIS SLM systems for length check and documentation after cutting process. Segments: Example Application: Segmenting Station with non-contact Part Length Measurement Link: www.extrudex.de/en |

|

ERBATECH GmbHPartner for development and production of winding and converting machines for the roofing and paper industry: ERBATECH is a mechanical engineering company from Erbach. ERBATECH manufactures production lines and machine modules for the production of membranes and shingles. ERBATECH offers machine modules for the reprocessing of primary products such as substrate materials via web control to impregnation / coating and sprinkling / cooling. ERBATECH uses ELOVIS μSPEED systems when it comes to precise cutting control in the production of rolls. Segments: Link: www.erbatech.de |

|

ROBUST HABICHT & HEUSER GmbH & Co.KGROBUST specializes in machines and components for industrial longitudinal and transverse cutting as well as for pre- and post-processing winding and sorting technology. The product range includes roll cutting and winding machines, longitudinal and cross cutting machines, machines for laminating, coating and gluing. ELOVIS discrete part length measurement systems complement ROBUST cutting machines to ensure length accuracy and 100% documentation of production. Segments: foil, wood and furniture, paper, composites, cell and battery production Example Application: Foil Format Cutting Machine Link: www.robust.de/en |

|

National Metrology Institute of Germany PTBPartner for the conformity assessment of length measurement machines: lndustry, trade and commerce in many cases count on the basis of length measurements of assets. In these cases, the conformity of the measuring instruments acc. to the Measurement Instruments Directive MID/2014/32 / EU or to the Measurement and Calibration Act must be certified. Among other things, such conformity assessments for devices for measuring lengths and their combination determine the field of activity of PTB. PTB has already evaluated numerous length measuring machines with ELOVIS length measuring technology. PTB issued a part certificate for the MID-COUNTER, both for length measurement with a laser encoder and a measuring wheel. Segments: conformity assessments according to MID 2014/32 / EU for measuring instruments for textile, non-woven, foil, cable, … Link: www.ptb.de |

|