Pipe separator machines with non-contact part length measurement

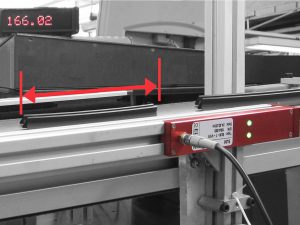

Weerth Handling Systeme manufactures systems for the non-cutting and burr-free cutting of metal pipes and tubes. For self-monitoring purposes, the pipe separation machines and cutting systems can be equipped with the SLM length-section light scanners for discrete part length measurement. The pipes / tubes are measured during production transportation in the 1/10 mm range and with repeat accuracies in the 1/100 mm range. With µMETER-SLM the production is secured and the quality is completely documented.

Typical application data:

- Measurement of pipes after separation or cutting, before sorting / packaging

- Production speeds: typically up to 1 pcs/sec or 60m/min

- Separation system without SLM system: only random sample inspection possible, accuracy: +/- 0.5mm/m

- 100% measurement with non-contact length measurement SLM, typical accuracy: 0.1mm/m

- Amortization: 2 months, integration of the measuring system into Weerth Anlagentechnik

Material examples:

- Precision pipes / tubes – straight pipes / tubes

- Diameters: from 4 mm to 120 mm

- Wall thickness: 0.4 mm to 3 mm

- Pipe materials: steel, stainless steel, aluminium alloys, copper alloys

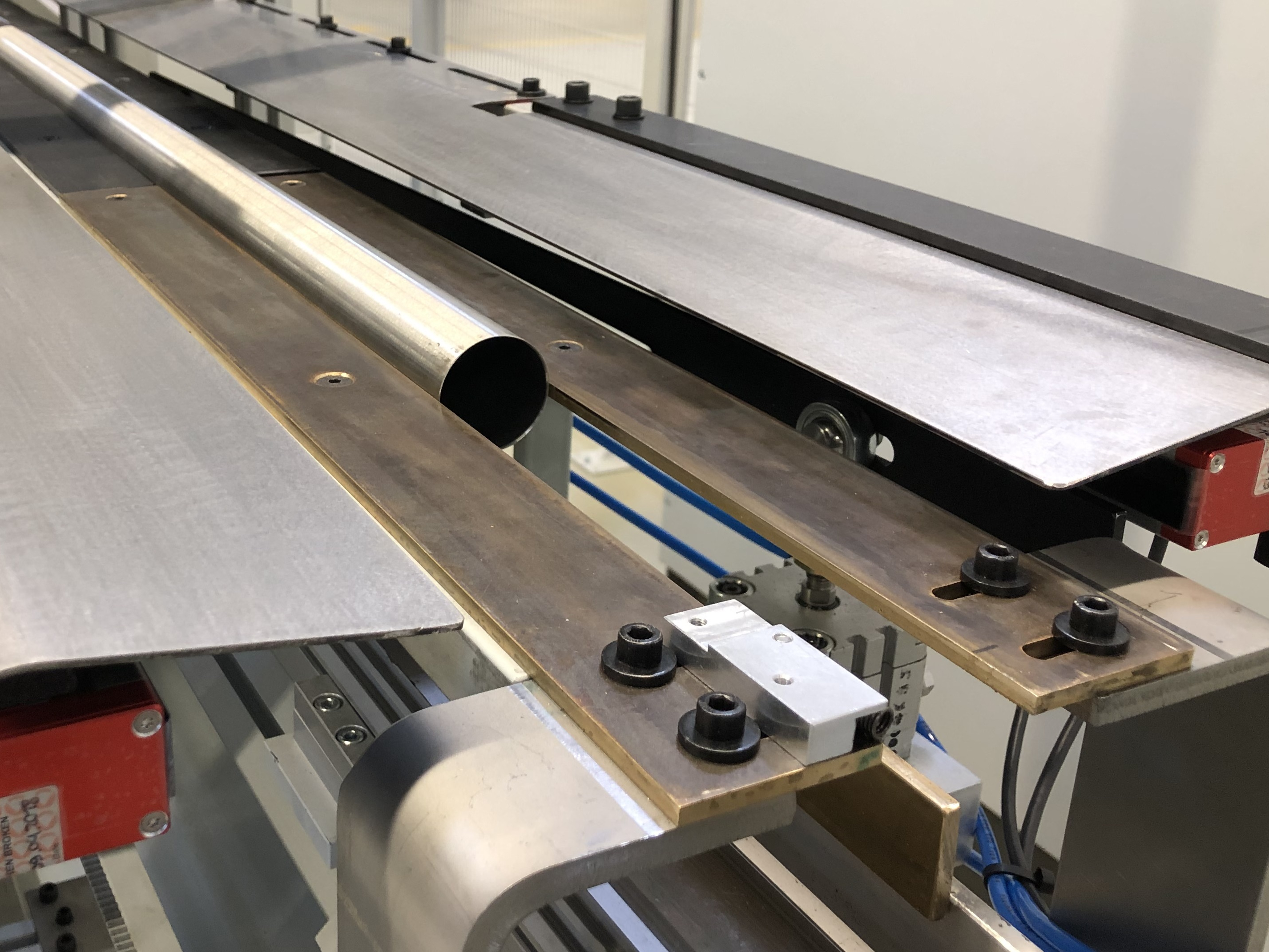

Weerth machines, which are extended by non-contact discrete part length measurement:

- Tube cutting machines

- Pipe separation machines

- Trennomat

- ROTAK

- Tube End Conditioning

Matching Products and Services

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

ELOVIS Services

ELOVIS offers the following services for the measurement of pipes, tubes and hose pieces:

- Advice on discrete part length measurement

- measurement services

- Help with length complaints of your customers

- OEM sensor developments in the area of piece length measurement