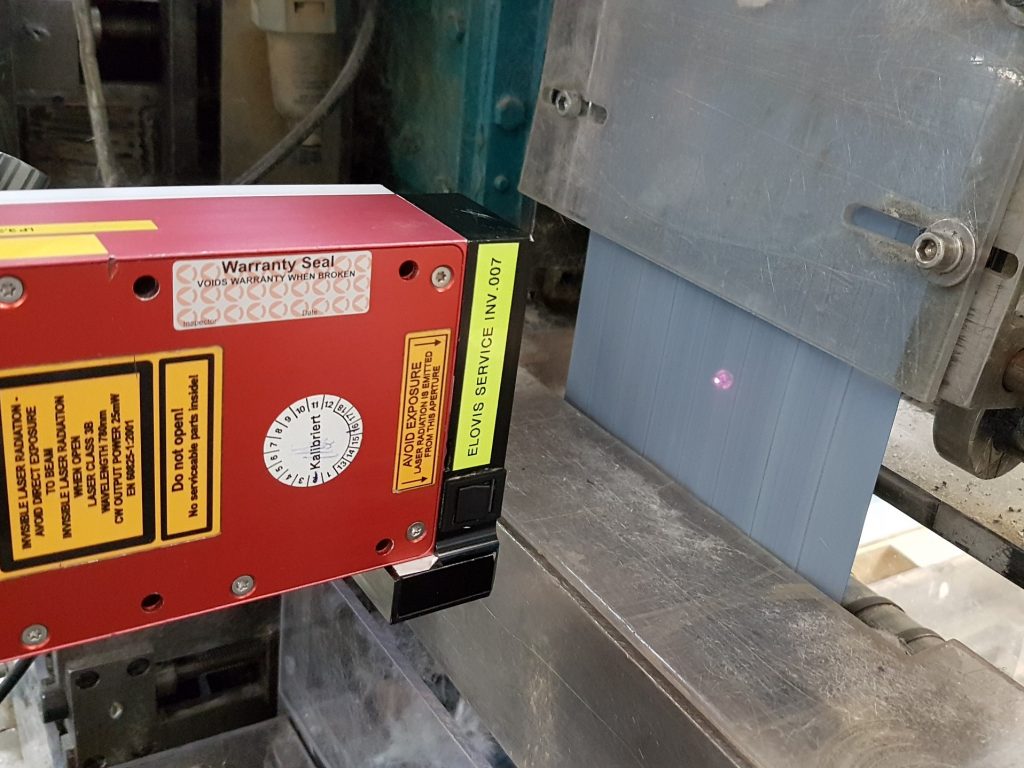

Abrasion-free, non-contact measurement of sensitive battery films

Battery separator foil must not show any holes, folds, kinks or damage, otherwise this may result in considerable damage. Non-contact length measurement does not endanger the surface and is highly accurate despite longitudinal bars and structures. μSPEED laser encoders measure accurately without touching the separator foil and doing so permanently.

Typical application data:

- Path Velocity: typically up to 600 m / min

- Measurement accuracy with tactile measuring equipment or via drive: typically 0.5 – 1%

- Measurement accuracy with non-contact length measurement μSPEED: typical: 0.03%

- Amortization: 3 months, direct encoder replacement, no other modifications needed

Material examples:

- Battery separator foil, separator foil, battery foil, plastic foil with longitudinal structure, …

- microporous film, film with longitudinal bars, structured film, spacer film, …

Machines equipped with non-contact length measurement:

- Roll cutting machines, roll cutter, cross cutter, lengthwise cutter

- Winding machines, rewinder, re-roller, doctor roller

- extruders, film casting machines, calenders

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services for the measurement of films:

- Advice on length and speed measurement

- Measurement & calibration services

- Help with length complaints of your customers

- OEM sensor developments in the field of length and speed measurement