Surface and diameter independent length measurement

Length measurement of cable and flat cable is done in many different applications. For example, already in production, in sheathing lines after extrusion or the stranding line, or during rewinding and assembly, i.e. length cutting. Due to the high raw material prices, the ordered sales lengths must be adhered to as precisely as possible. Too short cable lengths or wire lengths result in complaints. Too long lengths are a drain on the sales margin. The µSPEED non-contact laser encoder systems provide maximum accuracy, reliability and longevity. All materials and surface qualities are measured, starting from a diameter of approx. 0.2 mm.

Typical application data:

- Length measurement of insulated cables, bare cables, wires of small and large diameters

- Path speeds: up to approx. 2,500 m/min (rarely higher)

Measuring accuracy with tactile measuring equipment or via drive: typically 1 – 2 %. - Measuring accuracy with non-contact length measurement µSPEED: typically: 0.03 %

- Amortization: 1 month, direct encoder replacement, no other modifications necessary

- Translated with www.DeepL.com/Translator

Material examples:

- Extruded cables, single cable strands, …

- Multi-core cables, flat cables, power cables, submarine cables, …

- Stranded cables and wires

- Wire, drawing wire, bare wires, enamelled wires

Machines which are equipped with non-contact length measurement:

- Sheathing line, extruder

- Winding machines, rewinders, slitting machines, slitter rewinders

- Winding machine, Rewinding machine, Cable cutting machine

- Taping machine, stranding machine, …

Matching Products and Services

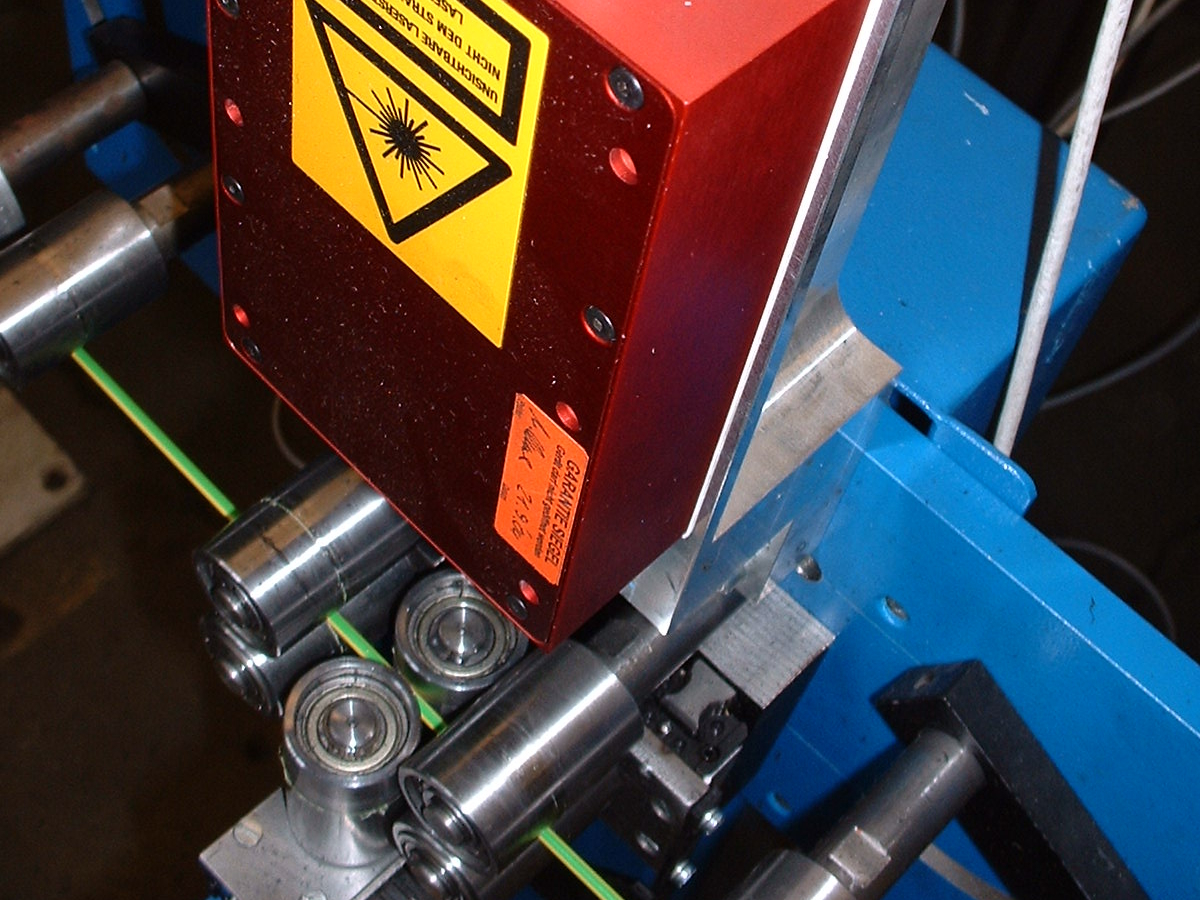

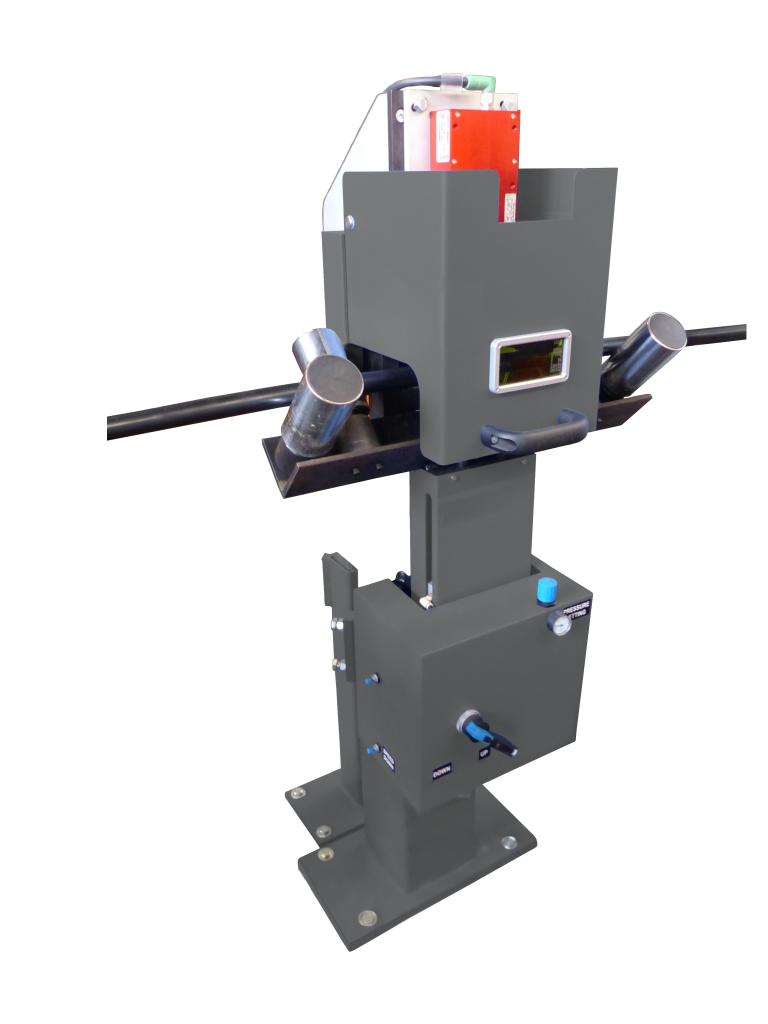

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services for the measurement of films:

- Advice on length and speed measurement

- Measurement & calibration services

- Help with length complaints of your customers

- OEM sensor developments in the field of length and speed measurement