Define target length and cut and assemble accurately

Do you avoid length additions or do you deliver excess length just to be safe? Do you have the strict requirement to deliver exactly the right length? … When reaching the target length, a cut should be triggered by the cut-to-length control. While doing so, the target length should be hit very precisely. Length additions cost a fortune in the long term and should therefore be avoided. Length additions can also be unwanted, to avoid expensive reworking steps. Achieving the precise target length requires a reliable, permanently accurate length measurement of all goods. Contact based tactile measurement instruments are exposed to wear and contamination. At high accelerations, tactile measuring equipment is exposed to slippage. Non-contact length measurement systems from ELOVIS which are used for cut-to-length control, deliver target lengths with consistently high accuracy.

Typical Materials for a Cutting Control:

- Roofing Films, Roof Sheeting

- Carpets, Nonwoven, Textiles

- Cable, Wire

- Adhesive Films

- Profiles, Tubes, Strands

- Sand Paper

Typical Cutting Systems with Cut-to-Length Control:

- Roll Cutter, Cross Cutter

- Roll Winder

- Winding Machine

- Rewinder

- Flying Saw, Flying Scissors

- Belt Saw

Application Examples

Cutting Control in Pipe/Profile Extrusion

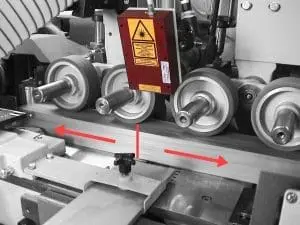

When sawing and cutting extruded materials, such as pipes, hoses and profiles, a slip-free length measurement is esse...

Roll Cutter for Roof Membranes

Due to the large number of different measuring surfaces, the CTL length cutting of sales rolls of roofing membranes, ...

Carpet Cutting Control

Hardly any material is more diverse than carpet and therefore difficult to measure in length. Carpeted floor can be 2...

Cutting Control on Cables and Wire

Cable and wire are rewound and cut at high speed. Due to the high raw material prices, the ordered sales lengths must...

CAMPEN off-line Slitters Rewinders

CAMPEN Machinery A/S off-line slitter and rewinders from Denmark are customer specific machines for rewinding and sli...

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services in this area:

- Consulting on the subject of cutting control and packaging

- Measurement and calibration services

- Help with length complaints from your customers

- OEM sensor developments in the area of cutting and sawing lines