Speed adjustment between conveyor belts and drives

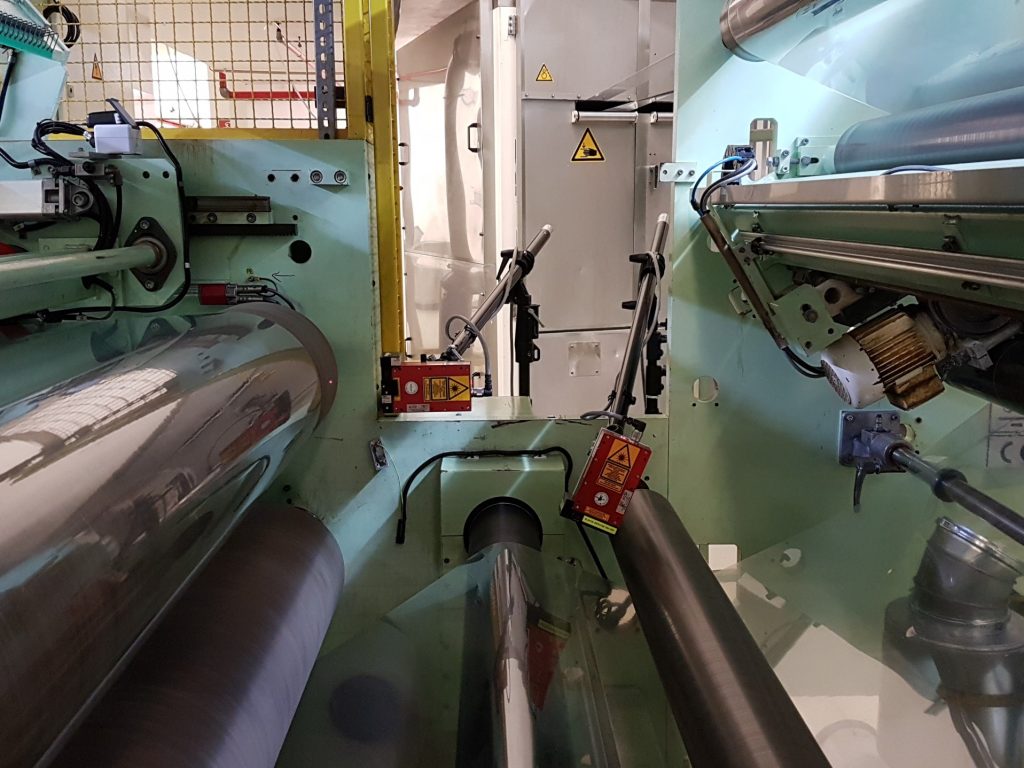

Systems with several drives, conveyor belts, screens or felts place particular demands on the synchronicity across all process stages and speed ranges. With contact measurement devices, measurement in the wet machine area is particularly difficult to realize. This works without a problem with contactless speed measuring systems. But even drives for materials with sensitive surfaces, or high-speed drives are better synchronized with non-contact measurement devices. Even machines with numerous drives or those for materials with strain-sensitive surfaces, or high-speed drives are better synchronized with non-contact measuring equipment. ELOVIS laser-encoders are also used in harsh environmental conditions.

Typical application data:

- Speeds: typically up to 3,000 m / min

- Measurement accuracy with tactile measuring equipment or via drive: only at low speeds

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.03%

- Amortization: 1 – 3 months, PC for displaying measured values and storage, tripod mounting

Measurement / Material Examples:

- Synchronization in the course of the initial commissioning, the plant inspection / trouble shooting

- Permanent synchronization of drives and belts as permanent system control

- belt, wire, felt speed in paper machines, fleece machines, calenders, rolling stands

Machines equipped with non-contact length measurement:

- Paper Machines, Tissue Machines, Crepe Formers, Yankee Cylinders

- Nonwoven machines, felting machines

- Rolling mills, rolling machines and winding machines

- Extruders, film casting machines, calenders, laminating machines, fabric inspection machines

Matching Products and Services

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services for speed synchronization:

- Advice on speed measurement

- Measurement & calibration services

- Help with system malfunctions

- OEM sensor developments in the field of length and speed measurement