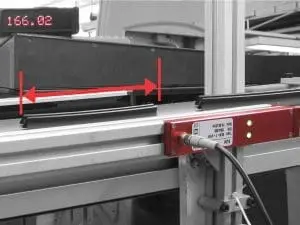

Non-contact final measurement of window profile lengths before packaging

Window profiles with lengths between 2.5 m and 7 m should be cut as precisely as possible and checked directly after the cutting. To do so, an inline non-contact length measurement directly after the saw is of great advantage. Both compliance with customer tolerances and the avoidance of rejects or length post-processing are targeted. The two-parted length-section light scanner SLM/2 covers the entire measuring range of up to 4.5 m in between the shortest and the longest part, without having to be repositioned, changed or parameterized. With SLM/2 length-section light scanners, window profiles made of plastic, aluminum or wood are measured lengthwise without contact, precisely and maintenance-free.

Typical Application Data:

- Measurement of profiles after cutting, before packaging

- Production speeds: typically up to 80 m / min

- Problem with contact measuring devices: only sample inspection possible, accuracy: +/- 1mm/m

- Measurement accuracy with non-contact length measurement SLM: typically 0.1mm / m

- Amortization: 1 month, integration of the measuring system into the existing conveyor system

Material examples:

- Extruded profiles of hard and soft plastic as well as co-extrusion and tri-extrusion

- Materials: PVC, ABS, PP, PC, PMMA, ASA and TPU

- Products: window profiles, pipes, hoses, corrugated pipes, sealing profiles, …

Machines equipped with non-contact profile length measurement:

- Guillotine, cross cutter, cross divider, cutting machine

- Saw line, flying saw, continuous saw, punch

- Packaging lines, sorting lines, QS stations

Matching Products and Services

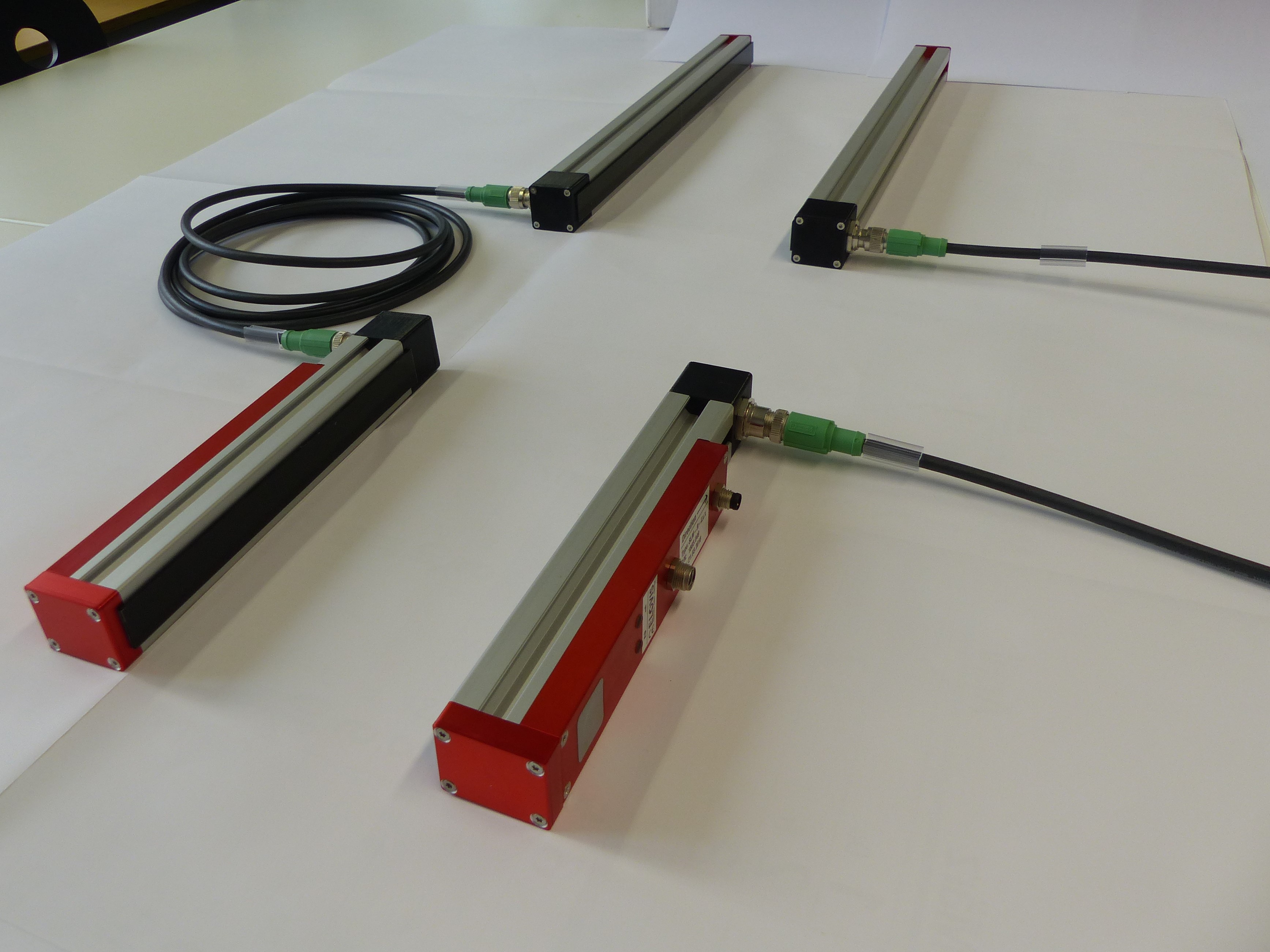

Length-Section Light Scanner

Discrete Part Length Measurement System

- Non-contact length measurement of discrete parts in the production process or in a cycle

- Highly accurate measurement of discrete parts, good/bad sorting and documentation

- LED-based length-section light scanner measurement technology, maintenance-free, optical, permanently calibrated

- Optical micrometer for the length measurement of profiles, tubes, plates

ELOVIS Services

ELOVIS offers the following services for the measurement of profile lengths:

- Advice on piece length measurement

- Measurement services

- Help with length complaints of your customers

- OEM sensor developments in the area of piece length measurement