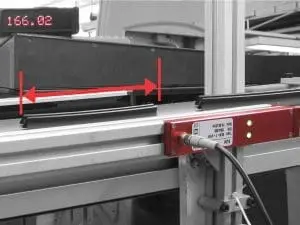

Final measurement of metal part lengths before further processing

Metal parts such as pipes, bolts, rods, slugs should have the correct part length. When operating presses and forging hammers, the parts ready for forming must not be under-sized or over-sized to ensure a perfect product result. Dimensional accuracy is automatically checked with SLM length-section light scanner even before inserting the parts. Precise, non-contact, maintenance-free and material-independent.

Typical Application Data:

- Measurement of metal parts after cutting, before further processing / packaging

- Production speeds: typically up to 120 m / min

- Problem with contact measuring devices: only sample inspection possible, accuracy: +/- 1mm / m

- Measurement accuracy with non-contact length measurement SLM: typically 0.1mm / m

- Amortization: 2 months, integration of the measuring system into the existing conveyor system

Material examples:

- Metal parts (bolts, rods, ingots, slugs, tubes, sleeves, profiles, …)

- Stamped parts, pressed parts, forgings

Machines in which non-contact piece length measurement offers advantages:

- Forging hammers, forging lines, compression molding, press, stamping

- Measurement after saw, guillotine, cross cutter, lengthwise cutter, cutting machine

- Measurement following the saw line, flying saw, continuous saw