Non-Contact Length Measurement - Use of Laser-Encoders - Videos

The following videos demonstrate the wide range of applications for

ELOVIS µSPEED laser encoder sensors in measuring roll lengths,

winding lengths and coil lengths, as well as for cutting control and for

cutting goods to correct length. The videos show the measurement of webs, tapes

and strand or coil goods made of a wide variety of materials, such as e.g.

textiles, film, paper, wire, cable and non-woven fabrics.

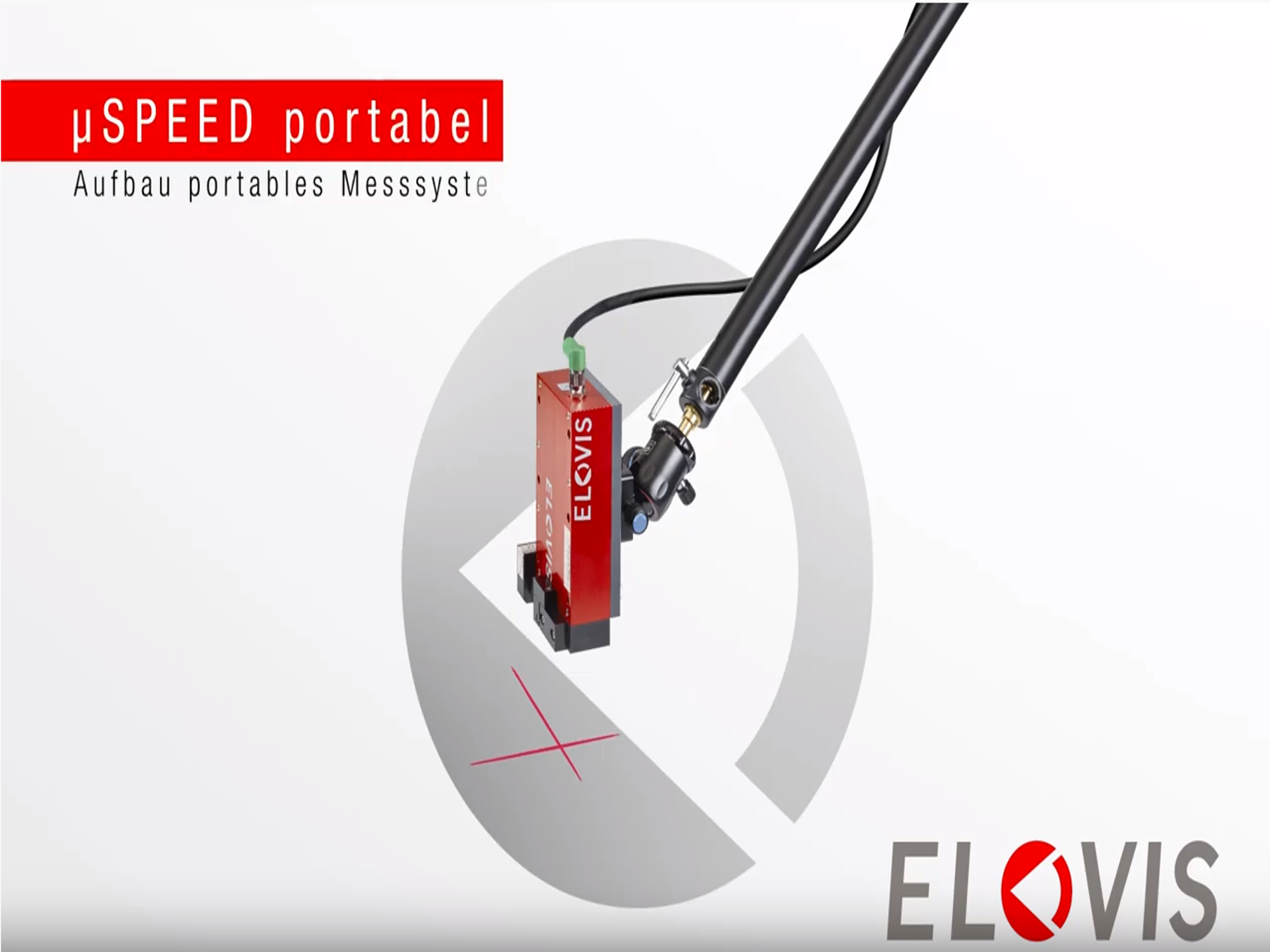

Laser-Encoder Length Measurement and Speed Measurement Systems With this product tutorial, we enable self-testers/users to use µSPEED systems independently, laser safe and with high precision and perfect measurement results. |  |

Calibrated Length Measurement and Material Inspection – µSPEED Calibrated non-contact length measurement from ELOVIS integrated into a combined inspection machine and winding machine for textiles, technical textiles, non-wovens, coated and laminated materials. |  |

Cutting of sound Insulation Material – µSPEED Length measurement prior to winding sales rolls with the portable µSPEED system. ELOVIS parallel measurement demonstrates the optimisation potential of non-contact measurement compared to conventional tactile length measurement. |  |

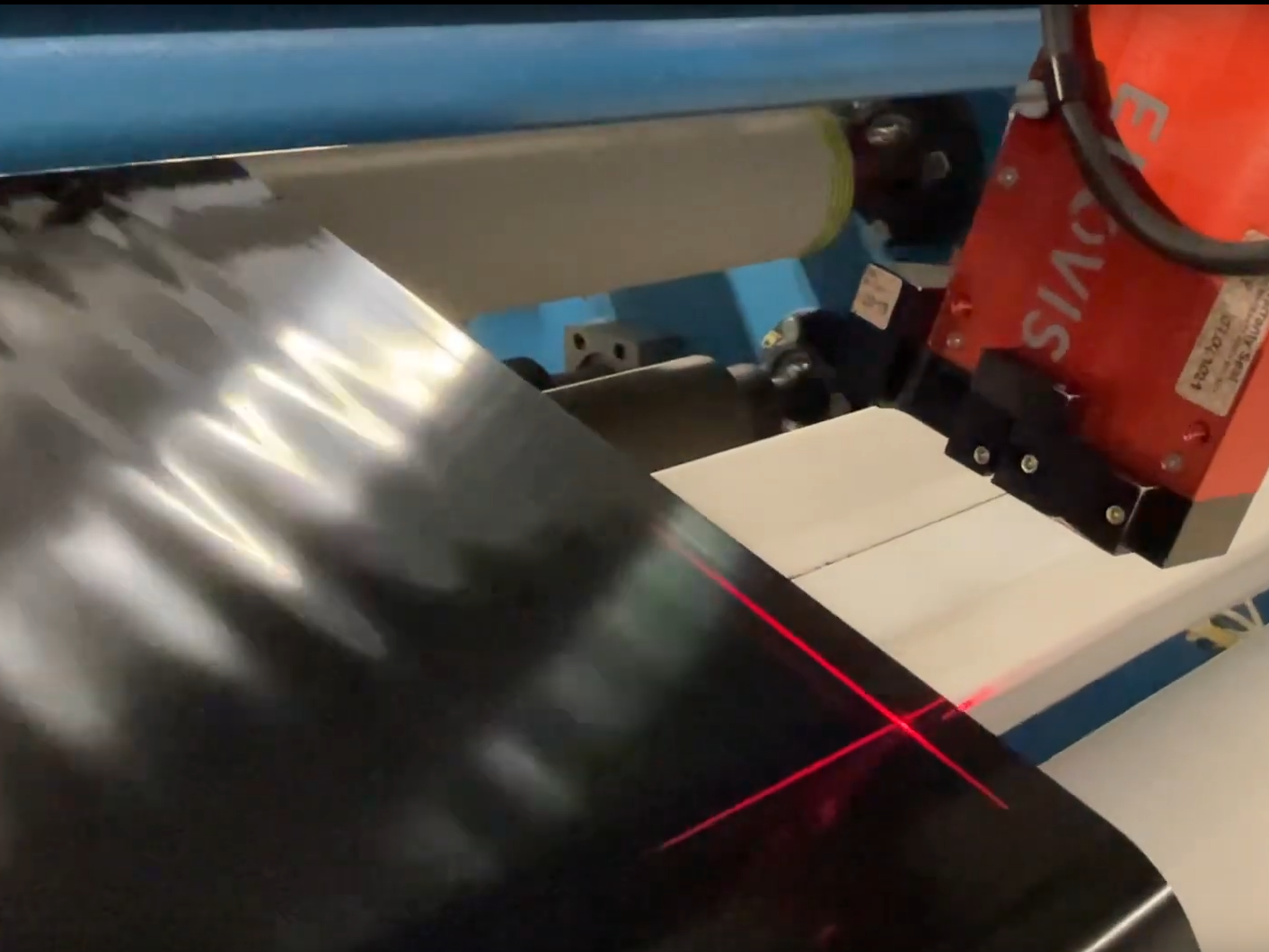

Length measurement of Black, Highly Reflective Film – µSPEED Non-contact length measurement of black, highly reflective self-adhesive film during longitudinal and cross cutting of large rolls into sales rolls/small rolls to ensure correct roll lengths. The µSPEED system delivers high measurement accuracy despite reflection, waves and creases in the material. |  |

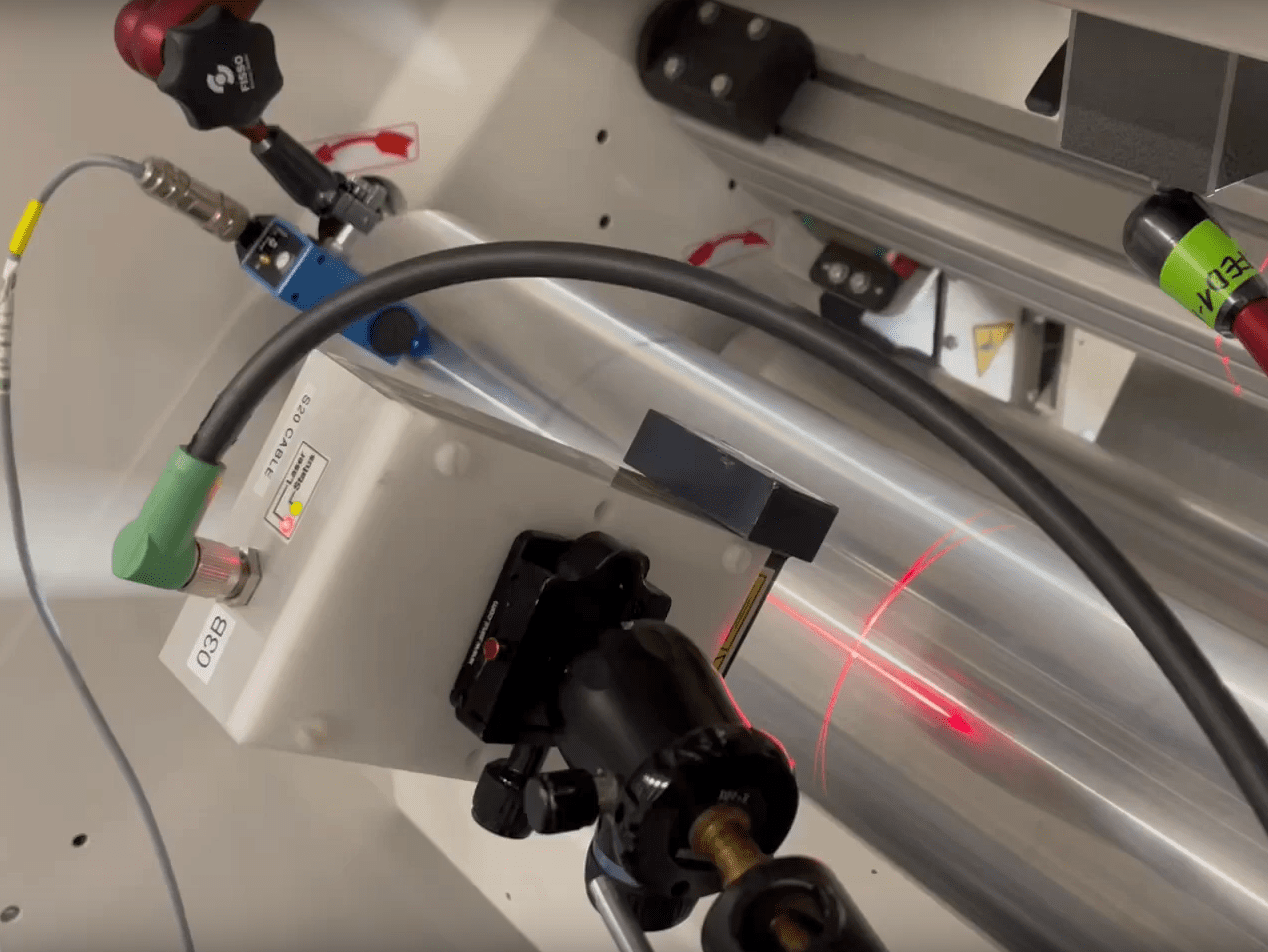

Differencial Measurement in betwen Cylinder & Foil – µSPEED Two µSPEED-SMART systems measure the difference in speed and length between a driven cylinder and a transparent film. The aim is to synchronise the drives and thus prevent scratches in the film. |  |

Length Measurement of transparent Adhesive Foil – µSPEED Comparing the machine counter with contactless length measurement using the µSPEED system enables the machine counter to be calibrated. This type of calibration often reveals length deviations of significantly more than 1.5%. When extrapolated to annual production, this can result in considerable sums. |  |

Measuring a submarine cable during unloading and loading – µSPEED When loading submarine cable-laying vessels, there is no turning back and no chance to measure a second time. µSPEED-PRO systems ensure that submarine cables are cut exactly at the right points and can therefore be laid correctly later on without having to make expensive length additions (€1,000/m). |  |

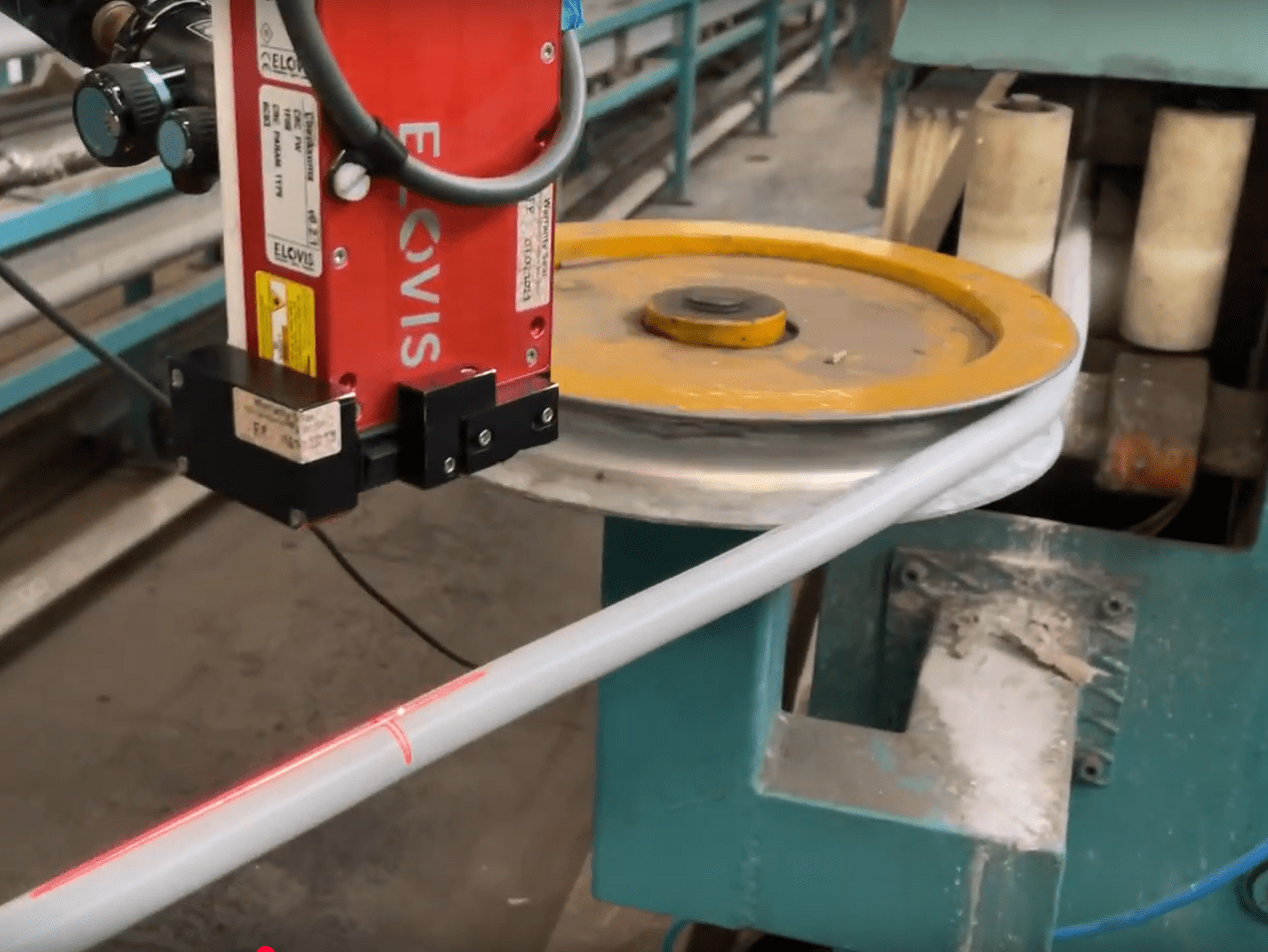

Non-contact Length Measurement in Cabel Extrusion – µSPEED Non-contact length measurement using ELOVIS µSPEED is permanently accurate, works independently of cable diameter, sheath and material type, and regardless of surface condition. |  |

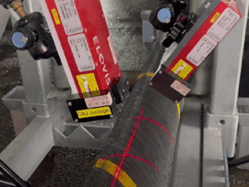

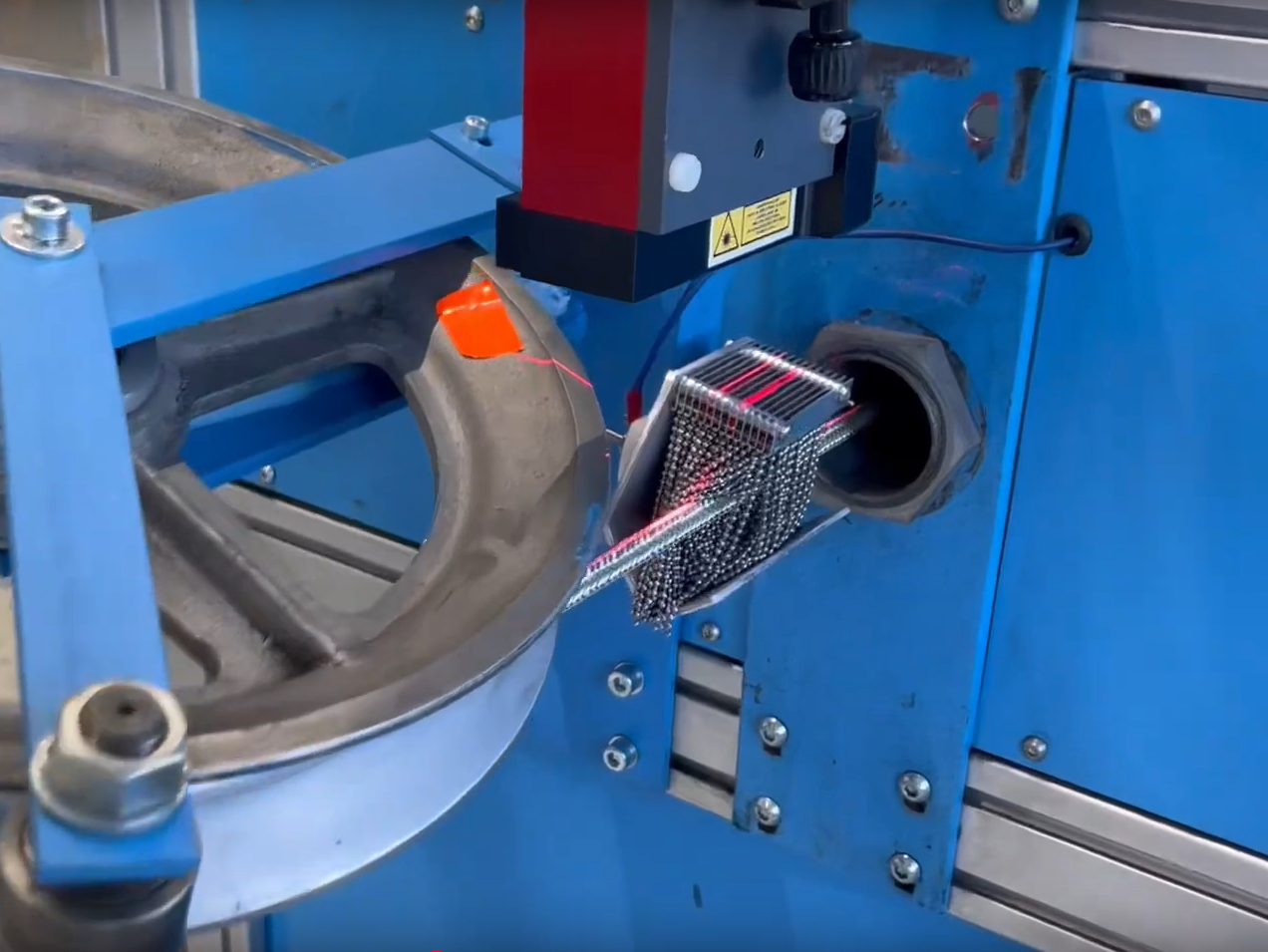

Length measurement on cables with braided metal sheathing – µSPEED uSPEED systems are also capable of measuring cables with a braided metal sheath safely and accurately in terms of length and speed. |  |

Length Measurement in Sheathing Production- µSPEED 1000 m cable length measured with an accuracy of better than +/- 0.5 m instead of the previous accuracy of + 20 m. The savings of almost 2% result in an ROI (return on investment) of less than 1 month. |  |

Speed Measurement on a casting machine – µSPEED When a rotational moulding machine operates at a constant withdrawal speed, the moulded parts, which are complex and energy-intensive to manufacture, are perfect. µSPEED is used to ensure that the moulding machine operates at a constant speed, thereby avoiding extremely costly rejects. |  |