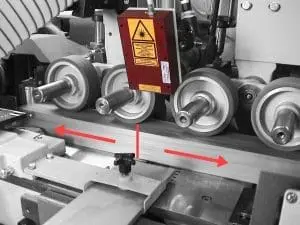

Surface and diameter independent marking control

In order to be able to measure cables commercially or in trade more easily and without tools, cables are printed or laser-marked with meter markings. The control of the marking unit is done during the cable production in the current process by a permanently length-accurate measurement methond. The non-contact μSPEED laser encoders, because of their reliability and material independence are often used for such marking applications.

Typical application data:

- Length marking of insulated, bare cables, small and large cable diameters

- Path Velocity: typically up to 1,000 m / min

- Measurement accuracy with tactile measuring equipment or via drive: typically 1 – 2%

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.03%

- Amortization: 2 months, direct encoder replacement, no other modifications needed

Material examples:

- Extruded cables, insulated cables

- Multi-core cables, flat cables, power cables, submarine cables, …

- ropes, wire ropes, ….

Machines equipped with non-contact length marking:

- Winding machines, rewinders, Roll cutting machines, roll cutters

- Spooling machine, rewinding machine, cable cutting machine

- extruder, stranding machine, banding machine