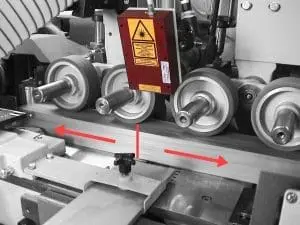

Non-Contact Measurement of soft, elastic surfaces

Length measurement of nonwoven, felt and material with high thickness variance and different grammages with consistently high measurement accuracy. Precise length measurement on soft and elastic surfaces. Non-contact measurement as a basis for length and square size or area accounting. The non-contact laser encoder system μSPEED serves as a measuring device which is maintenance-free, almost independent of material and can be used with consistently high accuracy at high and low speeds.

Typical application data:

- Path Velocity: typically up to 600 m / min

- Measurement accuracy with tactile measuring equipment or via drive: typically 2 – 5%

- Measurement accuracy with non-contact length measurement μSPEED: typical: 0.05%

- Amortization: 3 months, direct encoder replacement, no other modifications needed

Material examples:

- Nonwoven, felt, technical nonwoven, insulation materials, glass fiber fleece, spunbond spunlace

- Nonwoven fabric, filter fleece, roof underlayment, heat / impact sound insulation, geo-fleece, …

Machines equipped with non-contact length measurement:

- Roll Cutting Machines, Roll Cutter, cross cutter, lengthwise cutter

- Winding machines, rewinder, re-roller, doctor roller

- calenders, laminating machines, fabric inspection machine