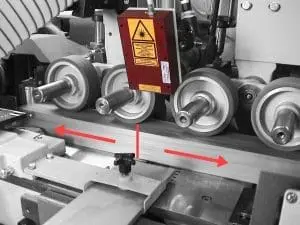

Measurement on fast-moving and touch-sensitive surfaces

Machine drives and material should be moved with the lowest possible differential speed. Ensuring this is not easy and speed difference check is e.g. not possible with contact measurement devices in case of high speed drives or with freshly coated materials. μSPEED laser encoder systems work without contact and are therefore predestined for this measurement application and for measuring slippage. μSPEED for the trouble shooting!

Typical Application Data:

- Cylinder and material speeds: typically up to 3,000 m / min

- Measurement accuracy with tactile measuring equipment or via drive: only at low speeds

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.03%

- Amortization: 1 – 3 months, PC for displaying measured values and storage, tripod mounting

Measurement / Material Examples:

- Cylinder speed in paper machines, rolling machines, calenders, coating machines

- Speed of conveyor belts, screening, felts in comparison with drive speeds

- Material speed of paper, nonwoven, fleece, foil, film, … in alignment with the drive

Machines equipped with non-contact length measurement:

- Paper Machines, Tissue Machines, Crepe Formers, Yankee Cylinders

- Nonwoven and nonwoven machines, felting machines

- Rolling mills, rolling machines, winding and winding machines

- Extruders, film casting machines, calenders, laminating machines, goods foam machines