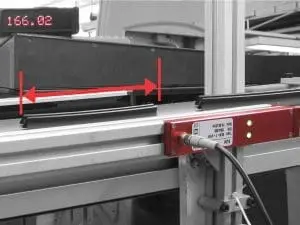

Non-contact remeasurement of profile lengths, pipes, hoses

High demands of the automotive, furniture, electronics or medical industry on the cutting accuracy of profiles make the 100% inspection of the pieces after cutting an important process step. Often the buyers of profile pieces also require documentation on the parts inspection. ELOVIS length-section light scanners measure in the accuracy range of 1/10 mm/m, sort the parts in good and bad and document the testing and sorting process.

Typical Application Data:

- Measurement of profiles after cutting, before packaging

- Production speeds: typically up to 50 m / min

- Problem with contact measuring devices: only sample inspection possible, accuracy: +/- 1mm/m

- Measurement accuracy with non-contact length measurement SLM: typically 0.1mm / m

- Amortization: 2 months, integration of the measuring system into the existing conveyor system

Material examples:

- Parts: Sealing profiles, tubes, hoses, corrugated pipes, windscreen wiper profiles, spoilers, …

- Extruded profiles of hard and soft plastic as well as co-extrusion and tri-extrusion

- Measuring materials: PVC, ABS, PP, PC, PMMA, ASA and TPU

Machines equipped with non-contact piece length measurement:

- guillotine, cross cutter, cross divider, cutting machine

- saw line, flying saw, continuous saw, punch

- Packaging lines, sorting lines, QS stations

ELOVIS services

ELOVIS offers the following services for the measurement of profile pieces:

- Advice on piece length measurement

- measurement services

- Help with length complaints of your customers

- OEM sensor developments in the area of piece length measurement