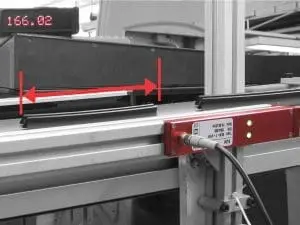

Non-contact final measurement of extruded, cut tubes

The final measurement of all tubes after the cutting allows a shortening of the setup time of the cutting system and thus a reduction of the machine rejects. ELOVIS length-section light scanners measure in the accuracy range of 1/10 mm/m, sort the parts in good and bad lengths and document the testing and sorting process.

Typical application data:

- Measurement of pipes after cutting, before packaging

- Production speeds: typically up to 50 m / min

- Problem with contact measuring devices: only sample inspection possible, accuracy: +/- 1mm / m

- Measurement accuracy with non-contact length measurement SLM: typically 0.1mm / m

- Amortization: 2 months, integration of the measuring system into the existing conveyor system

Material examples:

- Pipe pieces: pipes, tubes, fuel pipes, air pipes, corrugated pipes, protective pipes

- Hoses, compressed air hoses, hose line, cable protection hose, insulation hose

- Tubes and tubes made of hard and soft plastic as well as co-extrusion and tri-extrusion

- Materials: PVC, ABS, PP, PC, PMMA, ASA and TPU

Machines equipped with non-contact piece length measurement:

- guillotine, cross cutter, cross divider, cutting machine

- saw line, flying saw, continuous saw, punch

- Packaging lines, sorting lines, QS stations