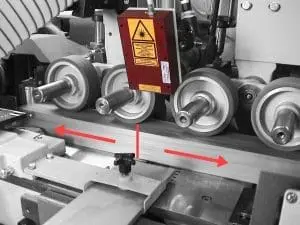

Inline length measurement after the chop saw or wedge galvanised unit

Solid construction wood, wooden beams, boards, plates made of MDF, HDF, OSB, … are mostly checked by hand after sawing and only on random samples for correct lengths. With the μSPEED Laser-Encoder gauge, the length check is performed on each piece with consistently high measurement accuracy. All lengths and cross sections can be measured with the non-contact μSPEED with continous high accuracy.

Typical application data:

- Material lengths: typically 1 m to 20 m

- Material speeds: typically up to 300 m / min (continuous measurement, without stop)

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.1% – 0.03%

- Amortization: 3 months, mounting for μSPEED required, air purge as dust prevention

Material examples:

- solid construction timber, wooden beams, wooden boards, profiled boards,

- Plates made of wood, MDF, HDF, OSB boards

Machines equipped with non-contact length measurement:

- sawing, punching, cross cutter, chop saw, finger jointing machine

- Machines with flying knife, flying saw

- Dividing lines, trimming line