Measurement of furniture panels, chipboard, drywall, …

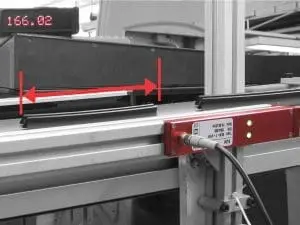

The woodworking industry is now confronted with high accuracy requirements. In order to make a profit, it is important to get the processes under control quickly even after a change of article. The ELOVIS length-section and cross-section light scanners have proven themselves in dimensional inspection. The inline measurement ensures transparency of the relevant dimensions from the first plate. For example, systems for furniture panels, chipboard, MDF, HDF and OSB boards or other drywall and insulation boards can be operated quickly and safely and with great reliability.

Typical Application Data:

- Measurement of plates and sheets after cutting, before packaging

- Production speeds: typically up to 250 m / min

- Problem with contact measurement devices: only sample inspection possible, accuracy: +/- 1mm / m

- Measurement accuracy with non-contact length measurement SLM: typically 0.1mm / m

- Amortization: 1 month, integration of the measuring system into the existing conveyor system

Material examples:

- Furniture mats (MFB melamine coated panels, printed panels, lacquered furniture panels, …)

- Particle boards (MDF boards, HDF boards, OSB boards)

- wood (firewood, KVH, beams, …)

- Construction and insulation materials (drywall, plasterboard and fiberboard, insulation material)

Machines equipped with non-contact piece length measurement:

- saw line, flying saw, continuous saw

- Guillotine, sheeter, cross divider, cutting machine, punch

- Packaging lines, sorting lines, QS stations