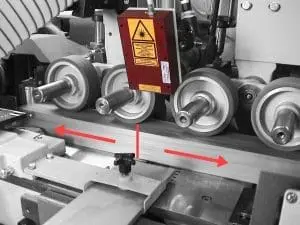

Inline length measurement after the saw or cutting unit

So far, pipes and profiles have only been randomly inspected for correct lengths after sawing. With the μSPEED gauge, the length check is carried out on each pipe with consistently high measurement accuracy. All pipe lengths and pipe diameters can be measured with μSPEED Laser-Encoder in non-contact way.

Typical application data:

- Material lengths: typically 1 m to 20 m

- Material speeds: typically up to 300 m / min (continuous measurement, without stop)

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.1% – 0.03%

- Amortization: 3 months, mounting required for μSPEED

Material examples:

- Tubes, carrier, rails, bars, rods, strips

- Profiles made of metal, plastic, rubber and gaskets

- Plasterboard, wood, MDF, HDF, OSB boards

Machines equipped with non-contact length measurement:

- sawing, punching, sheeter,

- Machines with flying knife, flying saw

- dividing lines