Find and eliminate reasons for waste production

Knowing the sources of errors is crucial to minimize waste. Steel sheets and other metal sheets are valuable materials. Sometimes the materials go through many processing procedures. Every single waste directly minimizes the achievable returns. By means of non-contact length measurement based on μSPEED, the lengths generated at the individual processing procedures can be recorded and compared in the product cycles. As a result, processes that are prone to waste are quickly identified and process errors can be eliminated.

Typical application data:

- Path Velocity: typically up to 2,000 m / min

- Measurement accuracy with tactile measuring equipment or via drive: typically 0.5-1%

- Measurement accuracy with non-contact length measurement μSPEED: typically 0.03%

- Amortization: 3 months, direct encoder replacement, no other modifications needed

Material examples:

- steel sheets, aluminum sheets, stainless steel sheets, galvanized sheets

- Non-ferrous metal sheets, coated and painted sheets

- Sheet metal of all kinds, surface and structure, with and without oil / emulsion

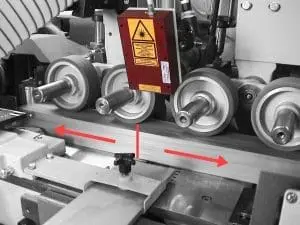

Machines equipped with non-contact length measurement:

- roll cutting machines, roll cutter, cross cutter, lengthwise cutter

- Winding machines, rewinder, rolling machine, rolling stand

- Finishing machines, painting machines, coating machines