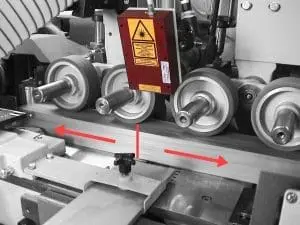

Slip-free, non-contact length measurement for cutting control

When sawing and cutting extruded materials, such as pipes, hoses and profiles, a slip-free length measurement is essential so that the cutting lengths are as correct as possible. Mostly flying saws are used to achieve the highest possible accuracy at high through-put. The output of encoder pulses for trigger control or to control the saw, the guillotine or the punch is most easily and accurately with the non-contact laser encoder μSPEED.

Typical application data:

- Removal Velocity: typically up to 40 m / min

- Measurement accuracy with tactile measuring equipment or via drive: typically 2 – 5 mm / m

- Measurement accuracy with non-contact length measurement μSPEED: typically 1 – 2 mm / m

- Amortization: 3 months, direct encoder replacement, no other modifications needed

Material examples:

- Extruded pipes, hoses, profiles, corrugated hoses, gaskets, …

Machines equipped with non-contact length measurement:

- Flying saw, flying scissors, flying knife, guillotine, punch

- band saw, band trigger, profile trigger, trigger control